Hydroscopic cellulose hydrogel and preparation method thereof

A cellulose hydrogel, water absorption technology, applied in the field of polymer materials, can solve the problems of non-biodegradable production and application, lack of strength, limited development, etc., and achieves easy recovery and recycling, simple and convenient operation, and is beneficial to The effect of industrial production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

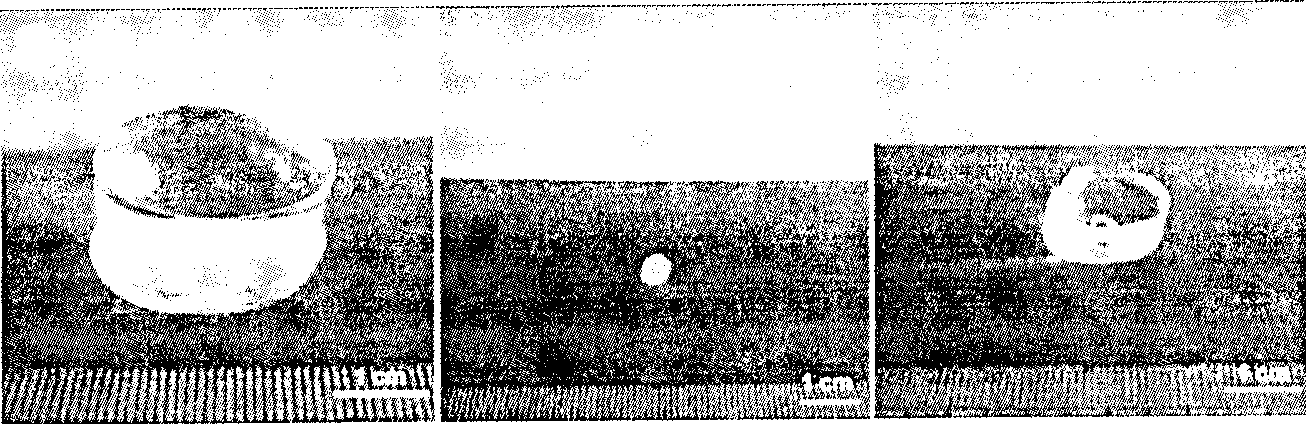

Image

Examples

Embodiment 1

[0010] Disperse 3 g of carboxymethyl cellulose in 97 g of a mixed aqueous solution containing 6 wt% NaOH and 4 wt% urea, and stir evenly at room temperature until the carboxymethyl cellulose is dissolved. 3 grams of cellulose (viscosity average molecular weight M η =3.5×10 4 ) dispersed in 97 grams of mixed aqueous solution containing 6wt% NaOH and 4wt% urea, pre-cooled to -20--10°C, thawed and stirred after 5-24 hours to obtain a transparent cellulose solution. Take 90g carboxymethyl cellulose solution and 10g cellulose solution and mix, wherein the weight ratio of carboxymethyl cellulose and cellulose is 9:1, and carboxymethyl cellulose and cellulose account for 3% of the solution. Add 10ml of epichlorohydrin dropwise to 100g of the mixed solution, raise the temperature to 60°C, and obtain a water-absorbing cellulose hydrogel with a weight ratio of carboxymethylcellulose and cellulose of 9:1 after 2 hours. The water absorption rate is 1000g / g.

Embodiment 2

[0012] Disperse 3 g of carboxymethyl cellulose in 97 g of a mixed aqueous solution containing 8 wt% NaOH and 10 wt% urea, and stir evenly at room temperature until the carboxymethyl cellulose is dissolved. 3 grams of cellulose (viscosity average molecular weight M η =3.5×10 4 ) is dispersed in 97 grams of a mixed aqueous solution of 8wt% NaOH and 10wt% urea, pre-cooled to -20--10°C, thawed and stirred after 5-24 hours to obtain a transparent cellulose solution. Take 80g carboxymethyl cellulose solution and 20g cellulose solution and mix, wherein the weight ratio of carboxymethyl cellulose and cellulose is 8:2, and carboxymethyl cellulose and cellulose account for 3% of the solution. Add 10ml of epichlorohydrin dropwise to 100g of the mixed solution, raise the temperature to 50°C, and obtain a water-absorbing cellulose hydrogel with a weight ratio of carboxymethylcellulose and cellulose of 8:2 after 6 hours. The water absorption rate is 800g / g.

Embodiment 3

[0014] Disperse 3 g of carboxymethyl cellulose in 97 g of a mixed aqueous solution containing 6 wt% NaOH and 4 wt% urea, and stir evenly at room temperature until the carboxymethyl cellulose is dissolved. 3 grams of cellulose (viscosity average molecular weight M η =3.5×10 4 ) dispersed in 97 grams of mixed aqueous solution containing 6wt% NaOH and 4wt% urea, pre-cooled to -20--10°C, thawed and stirred after 5-24 hours to obtain a transparent cellulose solution. Take 70g carboxymethyl cellulose solution and 30g cellulose solution and mix, wherein the weight ratio of carboxymethyl cellulose and cellulose is 7:3, and carboxymethyl cellulose and cellulose account for 3% of the solution. Add 10ml of epichlorohydrin dropwise into 100g of the mixed solution, raise the temperature to 40°C, and obtain a water-absorbing cellulose hydrogel with a weight ratio of carboxymethylcellulose and cellulose of 7:3 after 10 hours. The water absorption rate is 500g / g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| water absorption | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com