A kind of cooling clothing hydrogel-cotton composite material and preparation method thereof

A composite material, hydrogel technology, applied in the direction of plant fiber, fiber treatment, textile and papermaking, etc., can solve the problems of easy exudation, uneven dispersion of particles or powder, environmental pollution, etc., to achieve non-irritant and sensitization performance, light weight, and ease of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

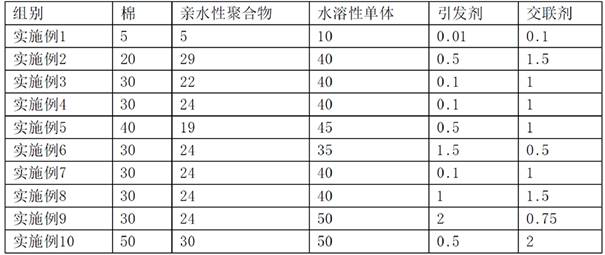

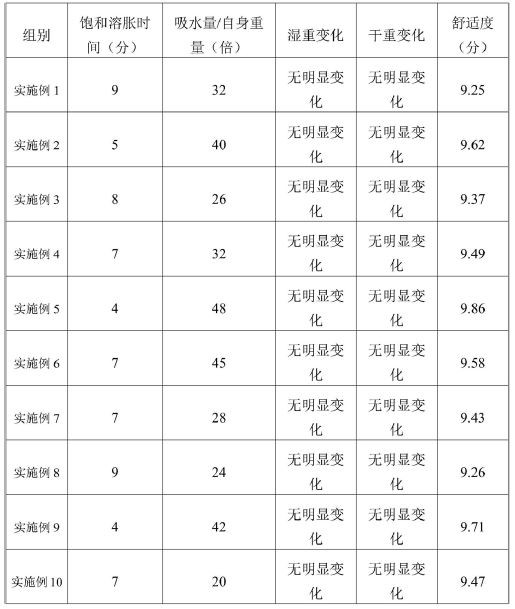

Embodiment 1

[0031] A kind of hydrogel-cotton composite material for cooling clothing, consisting of the following components by weight:

[0032] 5 parts of cotton cloth, 5 parts of polyvinyl alcohol, 10 parts of acrylic acid, 0.01 part of 2,4,6-trimethylbenzoyl-diphenylphosphine oxide, N , N 0.1 part of '-methylenebisacrylamide.

[0033] Its preparation method comprises the following steps:

[0034] 1) According to the above formula, weigh each component for later use;

[0035] 2) Take 2 parts of polyvinyl alcohol and dissolve in water to obtain polyvinyl alcohol aqueous solution;

[0036] 3) Soak the cotton cloth in the polyvinyl alcohol aqueous solution obtained in step 2) for 0.5 hours to obtain the soaked cotton cloth;

[0037] 4) Take out the soaked cotton cloth obtained in step 3), freeze it at -20°C for 12 hours, and then thaw it at room temperature to obtain the thawed cotton cloth;

[0038] 5) After dissolving acrylic acid in water, add 2,4,6-trimethylbenzoyl-diphenylphosphi...

Embodiment 2

[0043] A kind of hydrogel-cotton composite material for cooling clothing, consisting of the following components by weight:

[0044] 20 parts of cotton, 14 parts of polyvinyl alcohol, 15 parts of polyvinyl pyrrolidone, 30 parts of acrylamide, 10 parts of sodium acrylate, 0.5 parts of dibenzoyl peroxide, N , N 1.5 parts of '-methylenebisacrylamide.

[0045] Its preparation method comprises the following steps:

[0046] 1) According to the above formula, weigh each component for later use;

[0047] 2) Dissolve polyvinyl alcohol with water to obtain polyvinyl alcohol aqueous solution;

[0048] 3) Soak the cotton in the polyvinyl alcohol aqueous solution obtained in step 2) for 3 hours to obtain soaked cotton;

[0049] 4) Take out the soaked cotton obtained in step 3), freeze it at -20°C for 10 hours, and then thaw it at room temperature to obtain the thawed cotton;

[0050] 5) After dissolving acrylamide and sodium acrylate in water, add dibenzoyl peroxide, N , N '-methylene...

Embodiment 3

[0055] A kind of hydrogel-cotton composite material for cooling clothing, consisting of the following components by weight:

[0056] 30 parts of cotton yarn, 12 parts of polyethylene glycol, 10 parts of polyvinylpyrrolidone, 30 parts of acrylic acid, 10 parts of sodium acrylate, 0.1 part of 2,4,6-trimethylbenzoyl-diphenylphosphine oxide, bis(ethyl ethylene glycol) diacrylate 1 part.

[0057] Its preparation method comprises the following steps:

[0058] 1) According to the above formula, weigh each component for later use;

[0059] 2) Add water to dissolve polyethylene glycol to obtain polyethylene glycol aqueous solution;

[0060] 3) Soak the cotton yarn in the polyethylene glycol aqueous solution obtained in step 2) for 3 hours to obtain the soaked cotton yarn;

[0061] 4) Take out the soaked cotton yarn obtained in step 3), freeze it at -180°C for 0.5 hours, and then thaw it at room temperature to obtain the thawed cotton yarn;

[0062] 5) After dissolving acrylic acid ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com