Production process of indented steel stranded wire for prestressed concrete

A technology of notched steel strand and production process, which is applied in the direction of structural elements, building components, textile cables, etc., can solve the problem of core wire stress reduction, core wire edge slip and retraction, and reduce the grip between steel wire strand and concrete Power and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

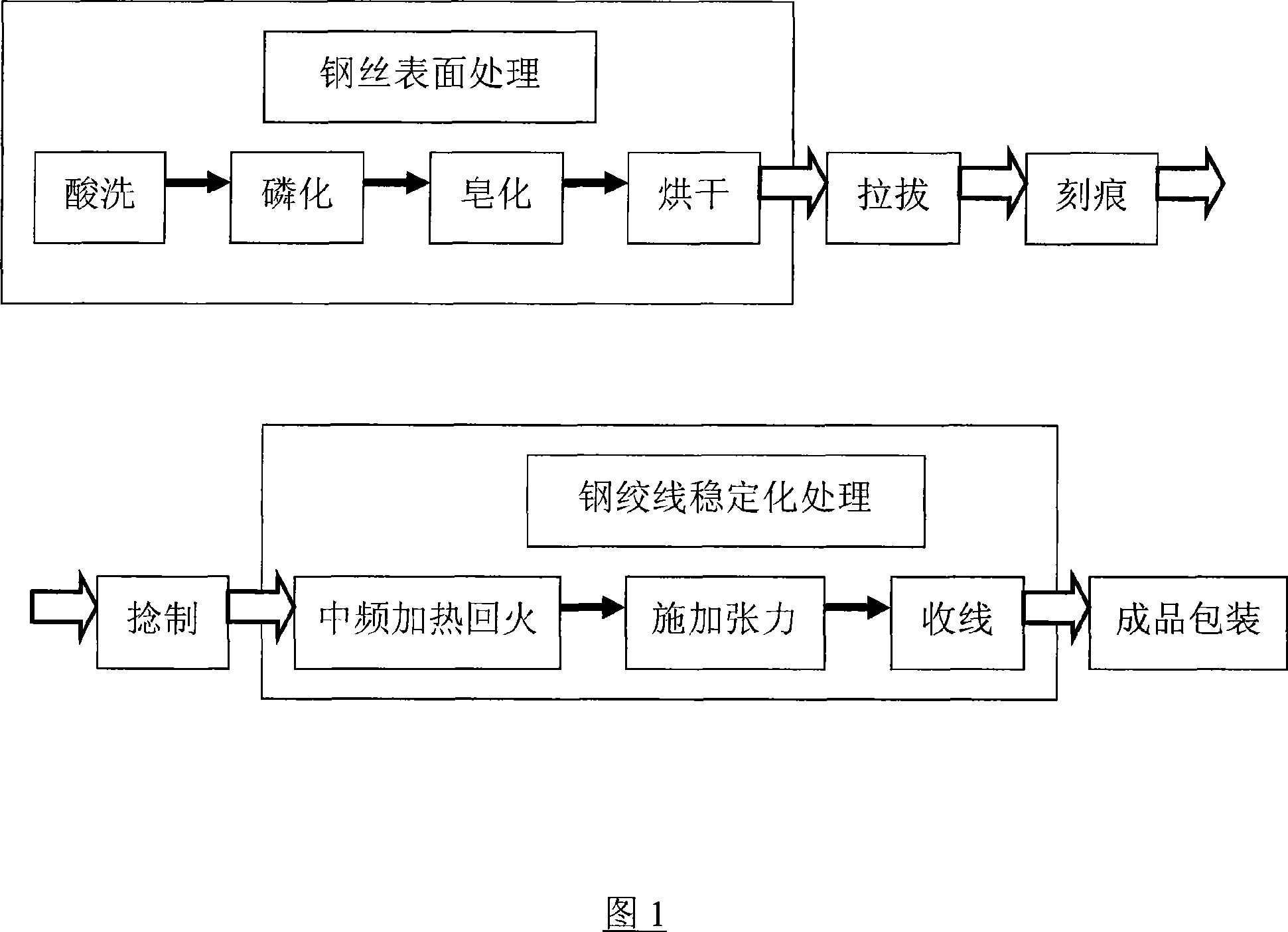

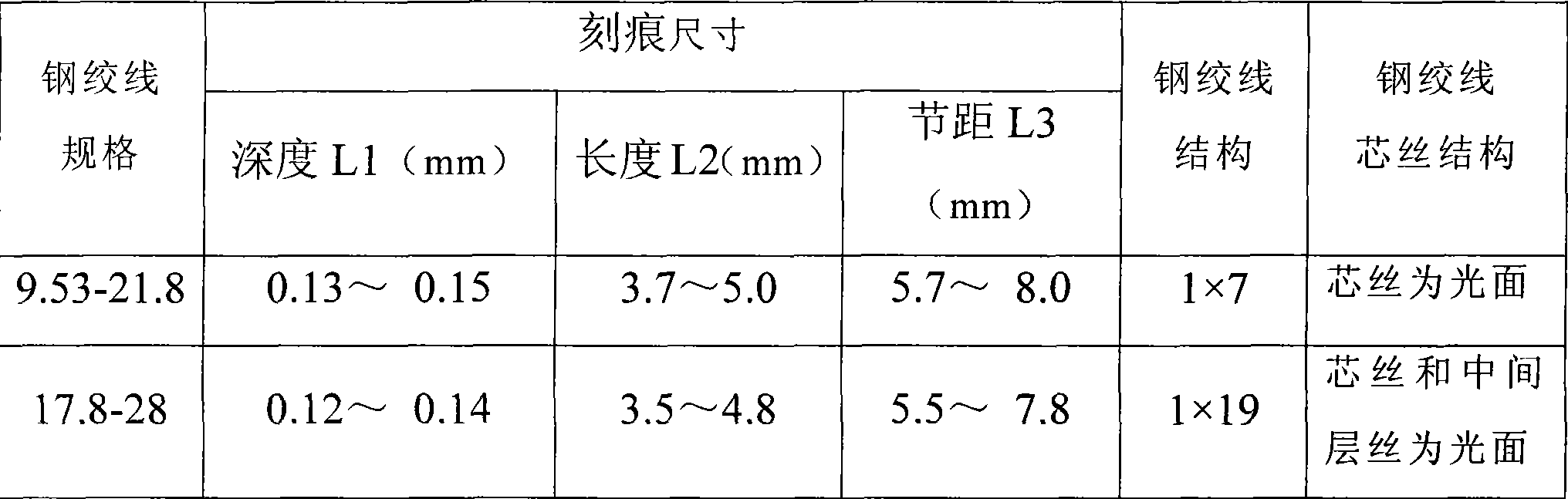

[0011] As shown in the accompanying drawings, it is the production process flow of the scored steel strand for prestressed concrete designed by the present invention, which adopts pickling→phosphating→saponification→drying→drawing→notching→twisting→heat treatment→winding→ Finished product packaging, steel wire that has passed the inspection is pickled with hydrochloric acid with a concentration of 80-180 g / l, and the FeCl in the pickling solution 2 ≤250g / L→Phosphating with zinc phosphate as the coating type and 2-3ml concentration of nitrite as accelerator, phosphating time 3-5min, total acidity 15-22ml, free acid point 6-10ml →Use 15%~22% soap flakes for saponification, and the saponification temperature is controlled at 80°C~90°C →Dry at a temperature of 90°C~100°C, and the drying time is controlled at 10min~20min→The smooth round steel wire passes through 5~ 10 passes of cold drawing, the compression rate of each pass of cold drawing is 15% to 22%, and the total compression...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com