Flexible dye-sensitized solar battery with stainless steel as substrate and preparation method thereof

A technology of solar cells and dye sensitization, applied in the field of solar cells, can solve problems such as high cost and complicated preparation process, and achieve the effects of improving fill factor, good bonding performance, and prolonging electronic life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

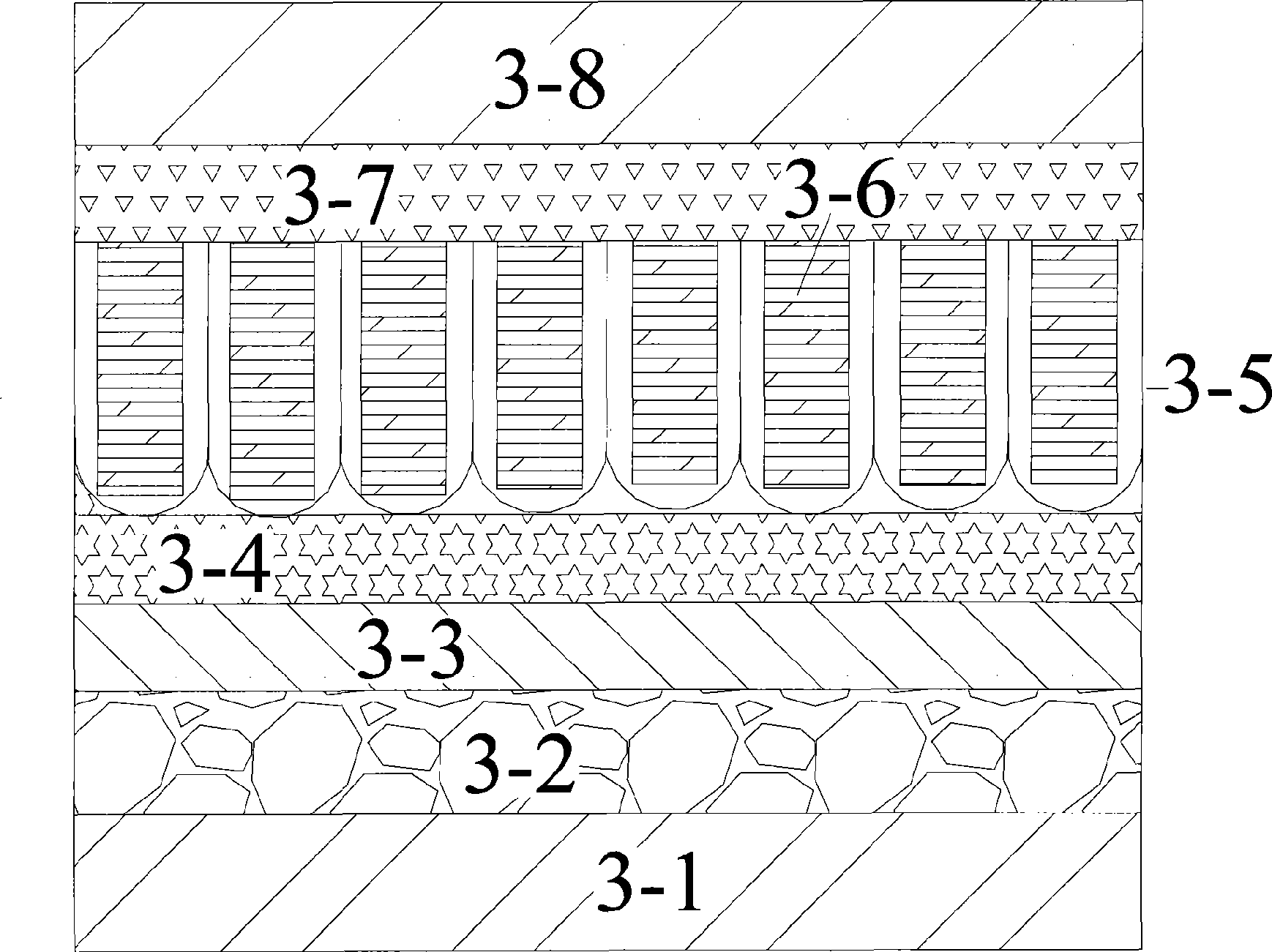

[0022] ① Dense SiO on stainless steel 2 Preparation of thin films and pure Ti thin films:

[0023] Select stainless steel with a thickness of 0.1-0.2mm as the substrate, first ultrasonically clean the stainless steel, and the sputtering vacuum reaches 7.0×10 -4 After Pa, use SiO 2 The target and titanium film are sputtered at 105-300W sputtering power, 0.5Pa argon pressure, and substrate temperature at room temperature-1000°C. The time for sputtering insulating thin film and titanium film is 5-15min and 0.5h-2h respectively.

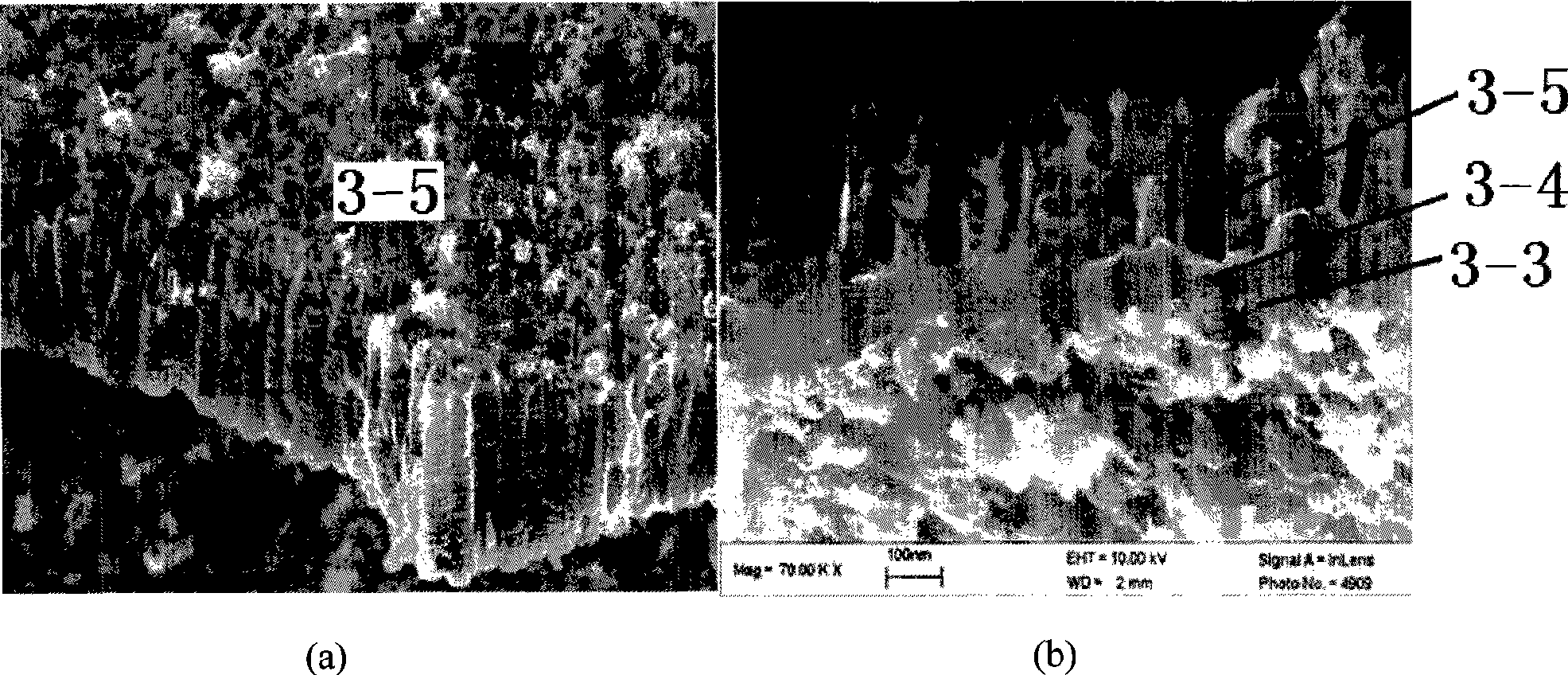

[0024] ② Flexible TiO 2 Preparation of nanotube / stainless steel photoanode:

[0025] The sputtered sample was nested on a metal fixture as an anode, and then the entire sample was completely immersed in the electrolyte for anodic oxidation at room temperature; the platinum sheet was used as the cathode, and the distance between the two electrodes was 30cm. 4 F is anodized in the electrolyte, the constant voltage is 10-60V, and the reaction time is 0....

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com