LED chip-containing photonic crystal side direction light extractor

A technology of light-emitting diodes and light extractors, applied in semiconductor devices, electrical components, circuits, etc., can solve the problems of large heat generation and stress concentration, and achieve the effects of stable performance, high luminous brightness, and improved external quantum efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] Below according to accompanying drawing and embodiment the present invention is described in further detail.

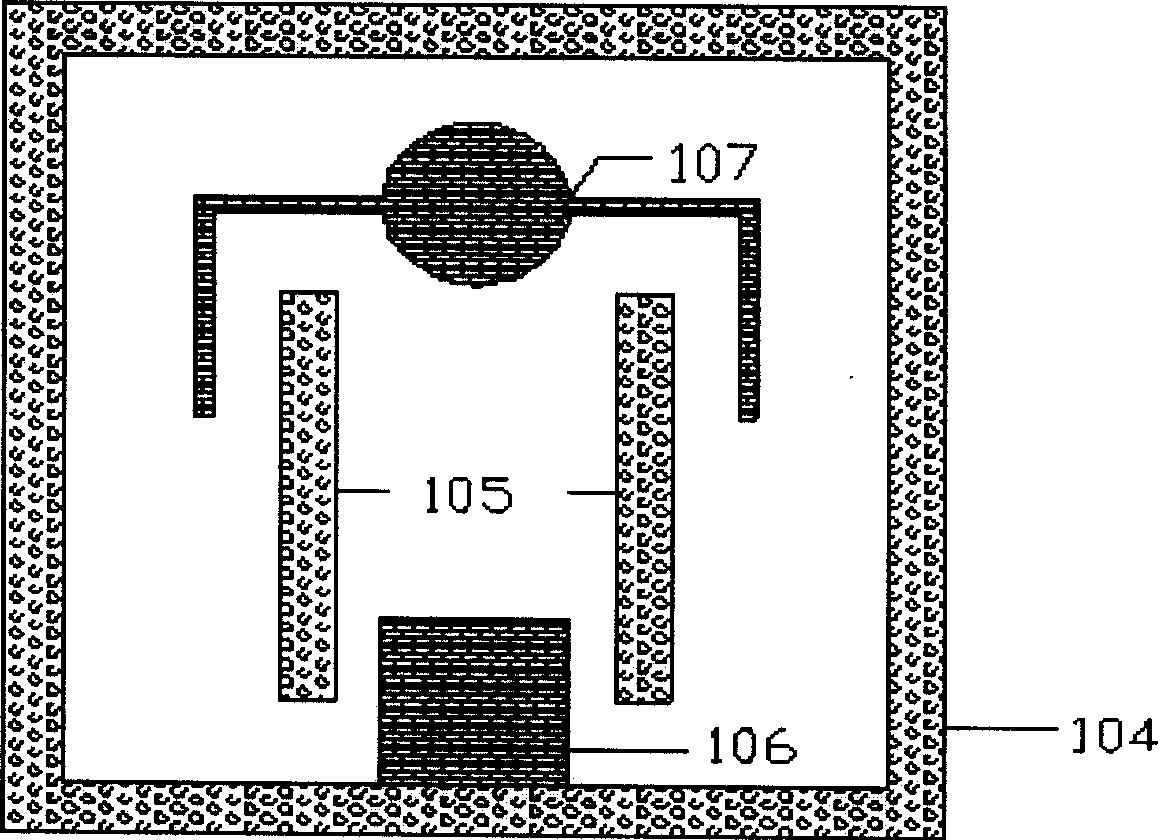

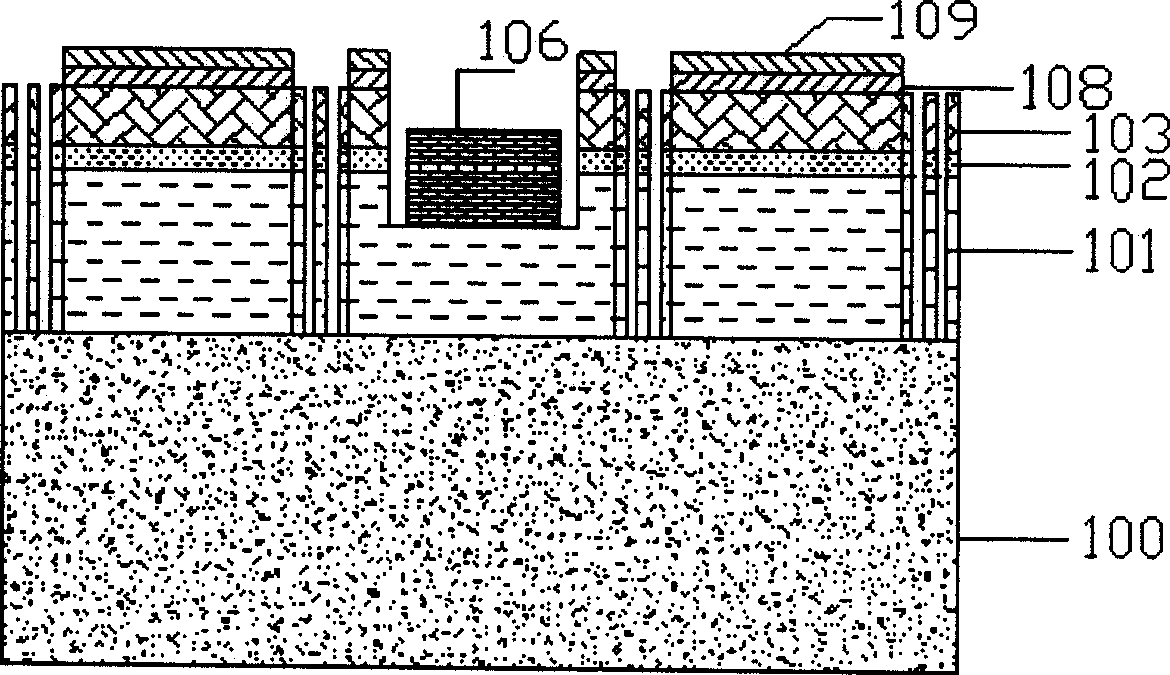

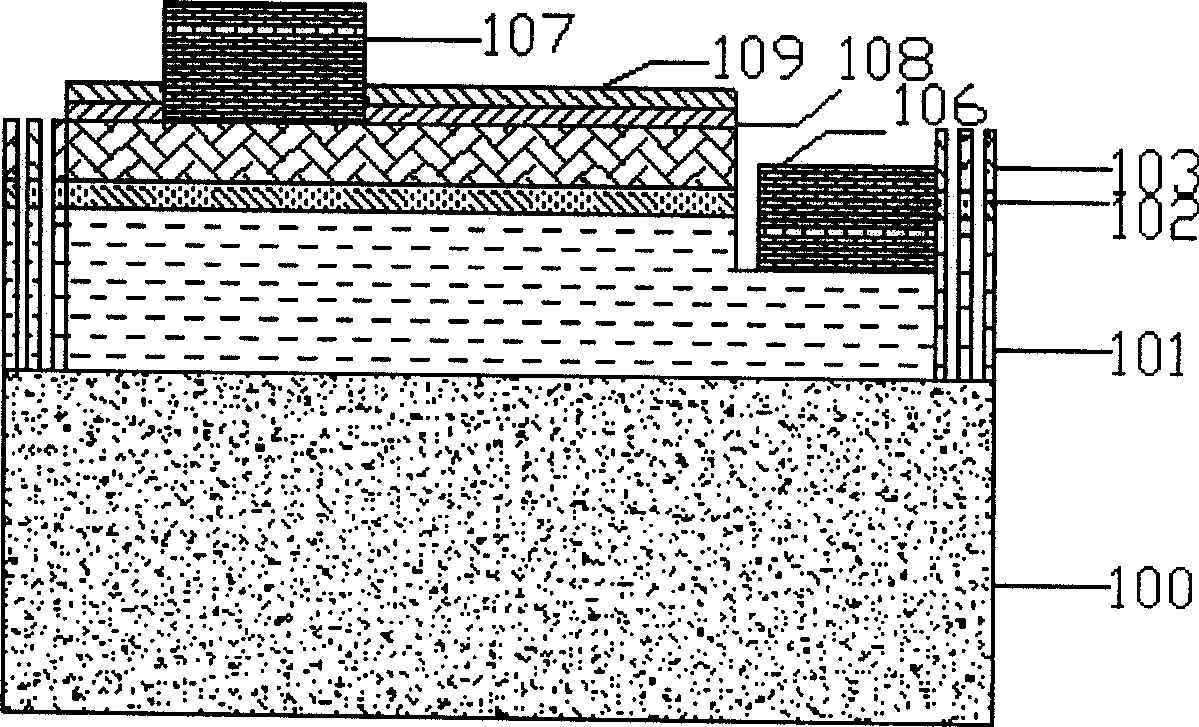

[0042] Figure 1A ~ Figure 1C Explanation of middle marks: 100—substrate, 101—n pole region, 102—active layer, 103—p pole region, 104—surrounding pillar array, 105—middle pillar array, 106—N electrode, 107—P electrode, 108— Current spreading layer, 109—protective layer.

[0043] Figure 2A ~ Figure 2IExplanation of middle marks: 200—substrate, 201—n pole region, 202—active layer, 203—p pole region, 204—passivation layer, 205—photoresist, 206—N electrode, 207—P electrode, 208— Current spreading layer, 209—protective layer.

[0044] see Figure 1A ~ Figure 1C , are top view, front view and side view of Embodiment 1 of the present invention.

[0045] see Figure 1A , is a top view of Embodiment 1 of the present invention, showing the relative positions of the peripheral column array 104 and the middle column array 105, the N electrode 106 and the P electrode 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com