Sodium sulfide evaporation concentration system and method

An evaporation concentration system and technology of alkali sulfide, applied in the field of concentration evaporation system of alkali sulfide, to achieve the effects of improving production efficiency, reducing scaling, and easy cleaning of scaling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

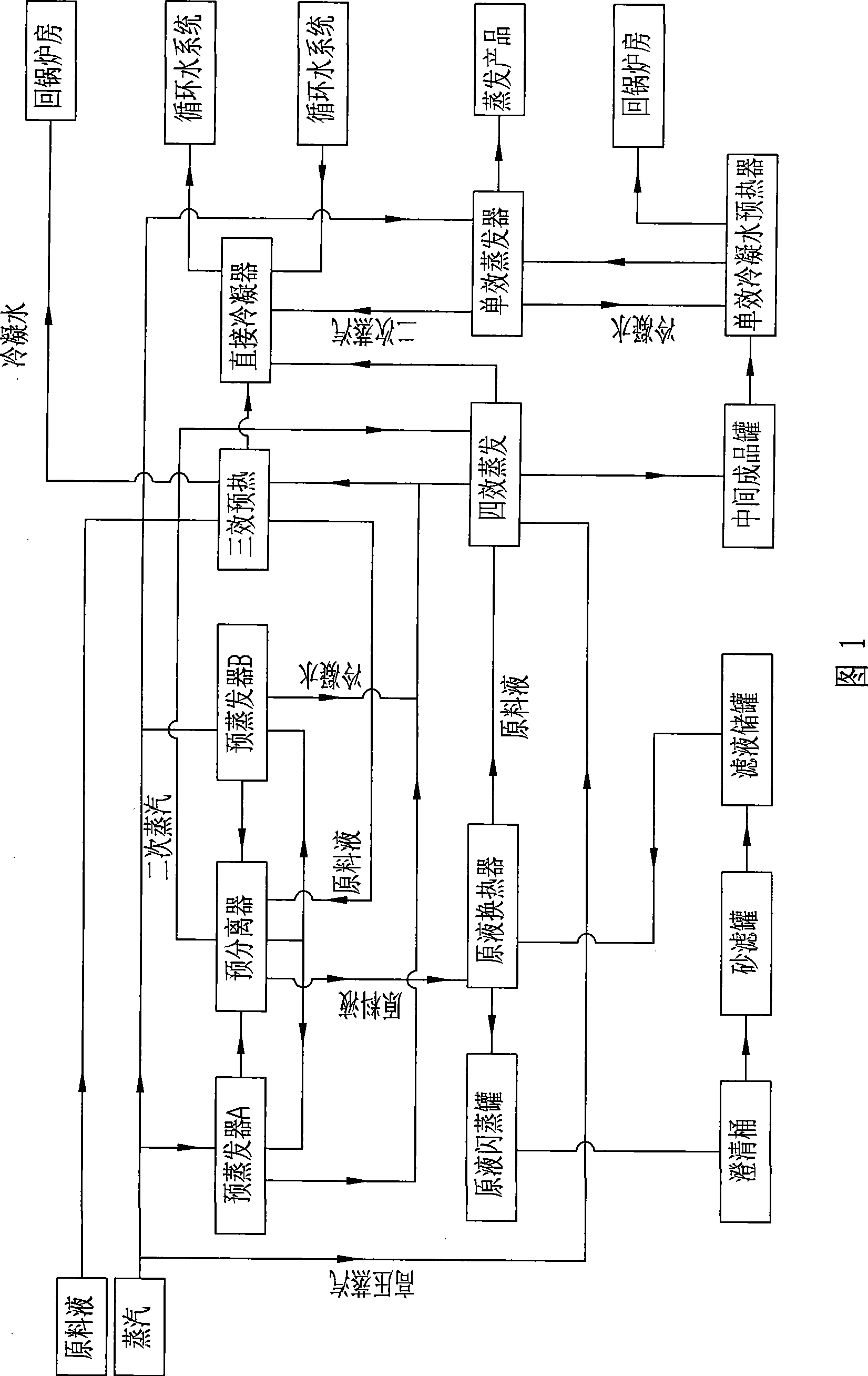

[0019] The present invention is described in further detail below in conjunction with accompanying drawing:

[0020] The alkali sulfide evaporation and concentration system of the present invention includes a material preheating part, a pre-evaporation part, a solution purification and solid separation part, a four-effect evaporation part, a single-effect evaporation part, a condensed water recycling part, and a cooling water part. Its specific equipment includes: boiler, three-stage preheater, pre-separator, pre-evaporator, raw liquid heat exchanger, raw liquid flash tank, clarification tank, sand filter tank, filtrate storage tank, four-effect evaporator, intermediate product tank , single-effect condensate preheater, single-effect evaporator, direct condenser and circulating water system.

[0021] The saturated steam produced by the boiler is used as the heat source of evaporation, the pressure of the saturated steam is 0.45MPa, and the temperature is 155°C; the raw materia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com