Finishing method of pore self-generation superhard abrasives grinding tool

A super-hard abrasive, super-hard abrasive particle technology, applied in the field of precision and ultra-precision grinding, can solve the problems of increased processing cost, workpiece burn, large wear ratio, etc., to achieve good durability and accuracy retention, low damage The effect of ultra-precision machining and simple production method

Inactive Publication Date: 2011-01-05

吴寿麟

View PDF0 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

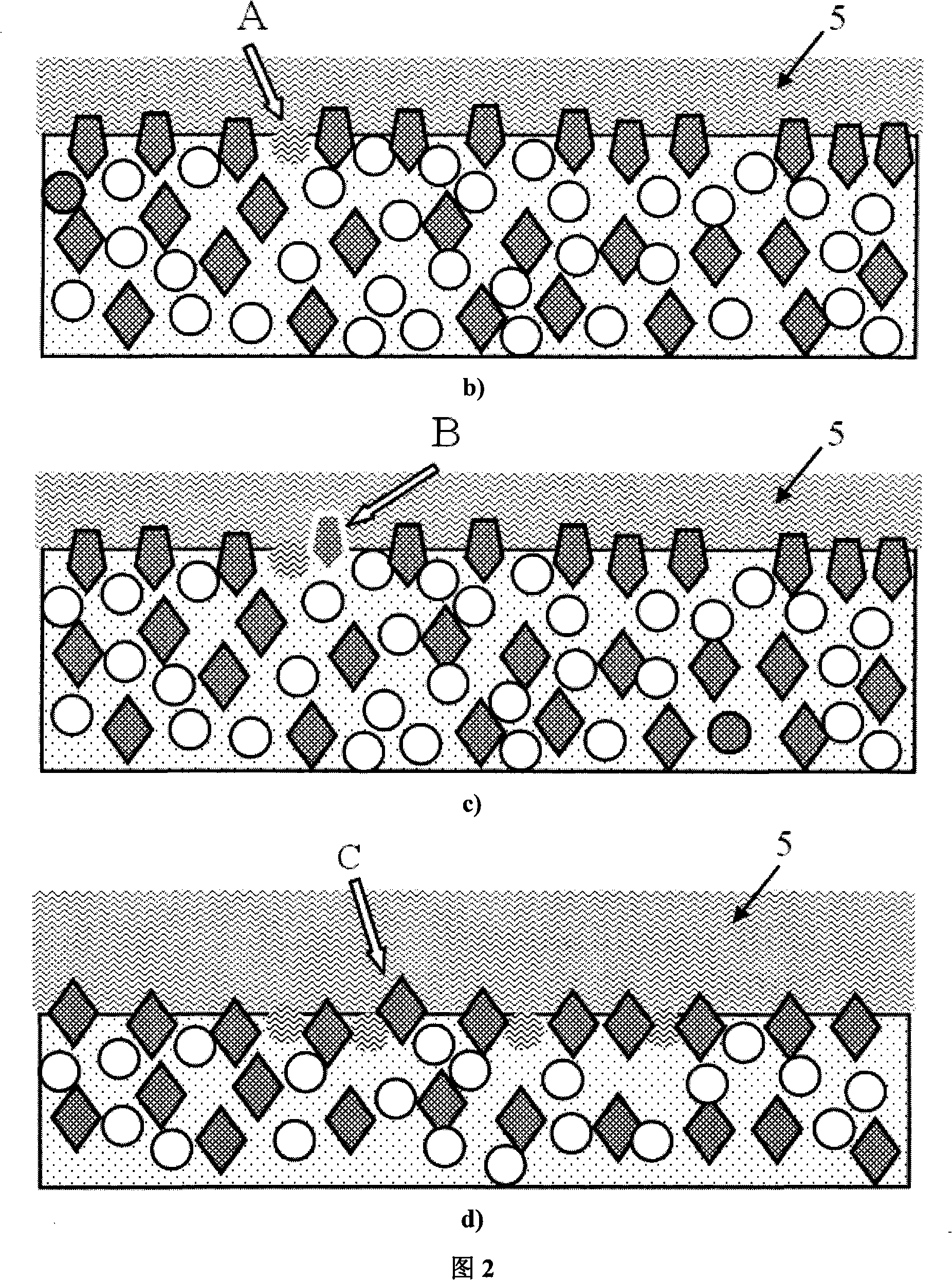

Since the strength of the oxide layer is much lower than that of the bond matrix, it is easy to be removed by the friction force and centrifugal force between the workpiece and the grinding wheel during the grinding process. The resulting cutting action (wear) is separated from the grinding wheel, increasing the ineffective loss of the grinding wheel

To sum up, although the current superhard abrasive grinding process can achieve a high material removal rate, it is difficult to trim due to the dense metal bond abrasive, which is likely to cause problems such as workpiece burns and affect the processing quality; Although abrasive tools and porous grinding wheels can effectively solve the problem of chip space, etc., the strength of the grinding wheel itself is low, and the wear ratio is large when processing difficult-to-machine materials such as structural ceramics, which increases the processing cost.

ELID technology can well solve the problem of online dressing of grinding wheels, but it often causes ineffective loss of ultra-fine superabrasive grinding wheels and increases production costs

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

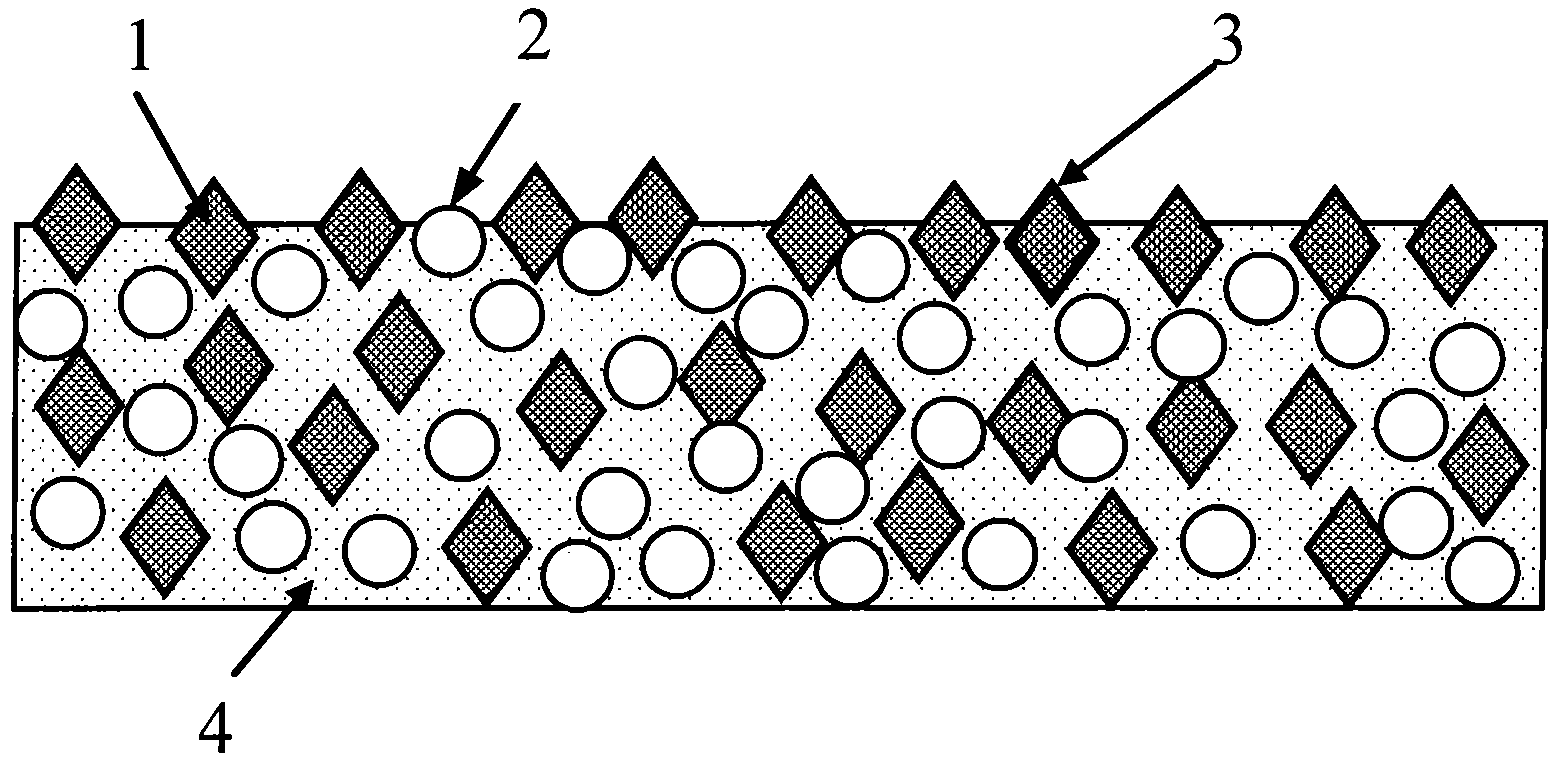

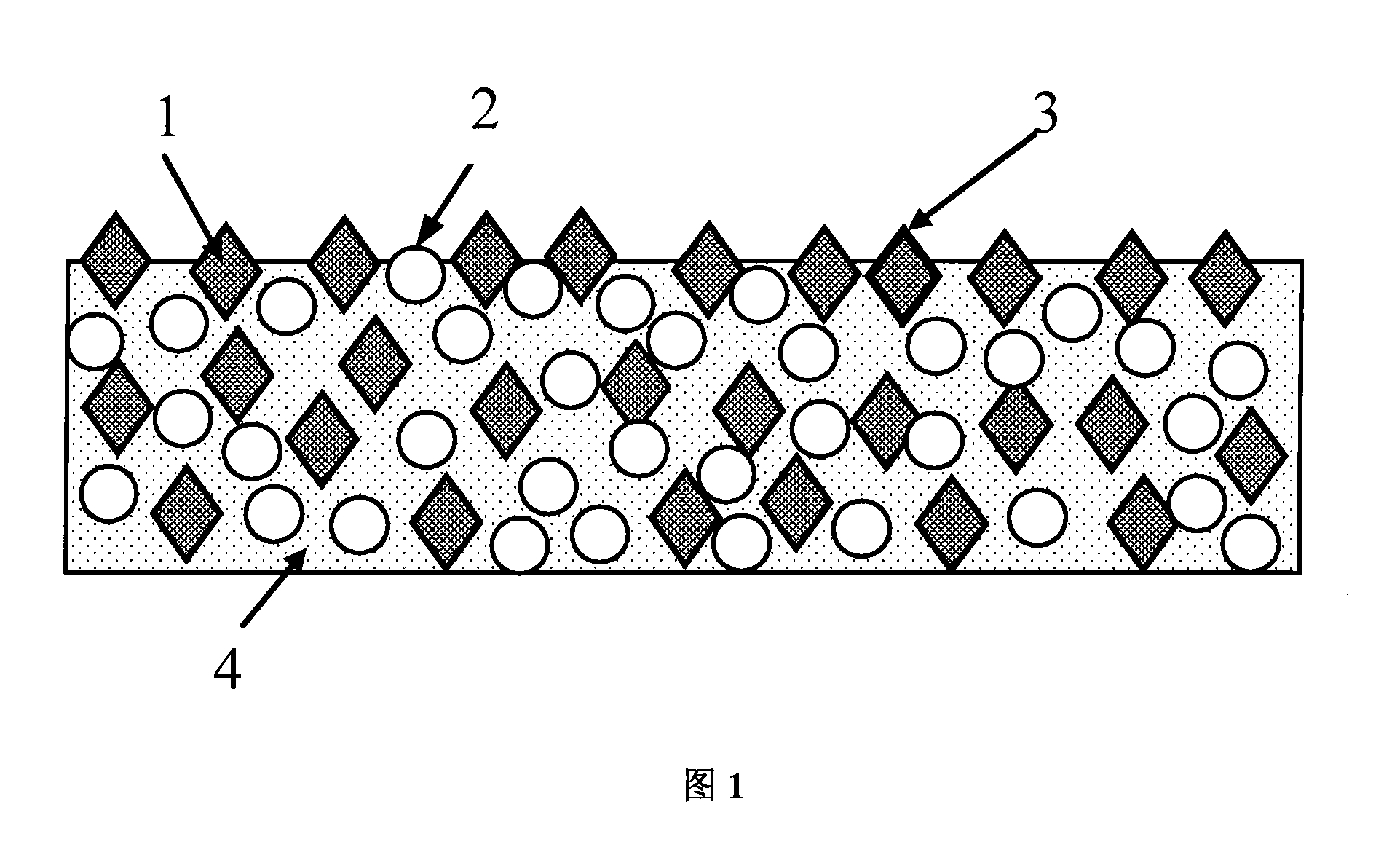

The invention discloses an automatic pore generation ultrahard abrasive grinding tool and a method for dressing the same. The grinding tool at least consists of abrasive grains, a bonding agent and a 'soluble' filling agent. The 'soluble' agent soluble in a certain solvent is added into the bonding agent of the automatic pore generation ultrahard abrasive grinding tool, and a layer of the 'soluble' filling agent can be coated on the ultrahard abrasive grain surface layer according to requirement. The 'soluble' filling agent and the bonding agent act together to hold the abrasive grains and ensure excellent strength of the grinding tool. In a grinding process of the grinding tool, when the abrasive grains on the surface of the grinding tool are passivated and the grinding tool needs to be dressed, the method can deliver the certain solvent to the surface of the grinding tool to dissolve the 'soluble' filling agent on the surface layer of the grinding tool and generate pores in the bonding agent to reduce the structural strength of the bonding agent and holding force of the bonding agent to the sounding abrasive grains and make the abrasive grains on the surface layer of the grinding tool easy to fall off, thereby automatically dressing the grinding tool and revealing new abrasive grains.

Description

A method for dressing self-generated superabrasive abrasives with pores technical field The invention relates to the field of precision and ultra-precision grinding, in particular to a pore self-generated superhard abrasive abrasive tool capable of forming pores on the surface layer of the abrasive tool during processing and a dressing method thereof. Background technique At present, grinding with superabrasive grinding wheels (diamond grinding wheels, CBN grinding wheels) is an efficient processing method for hard, brittle and difficult-to-machine materials with high precision. However, in the production and application of superabrasive abrasives for many years, it has also exposed its own inherent defects, mainly in: non-metallic bond superhard grinding wheels have low holding force on abrasive grains, easy to fall off, poor durability, and processing costs High; the metal bond superhard grinding wheel is difficult to dress, it is difficult for the abrasive grains to com...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): B24D3/32B24D3/04B24D3/00B24D3/10

Inventor 吕冰海袁巨龙熊万里邓朝晖戴勇

Owner 吴寿麟

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com