BCD semiconductor device and manufacturing method thereof

A semiconductor and device technology, applied in the field of semiconductor power devices, can solve the problem of high cost and achieve the effects of excellent performance, low manufacturing cost and low output impedance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

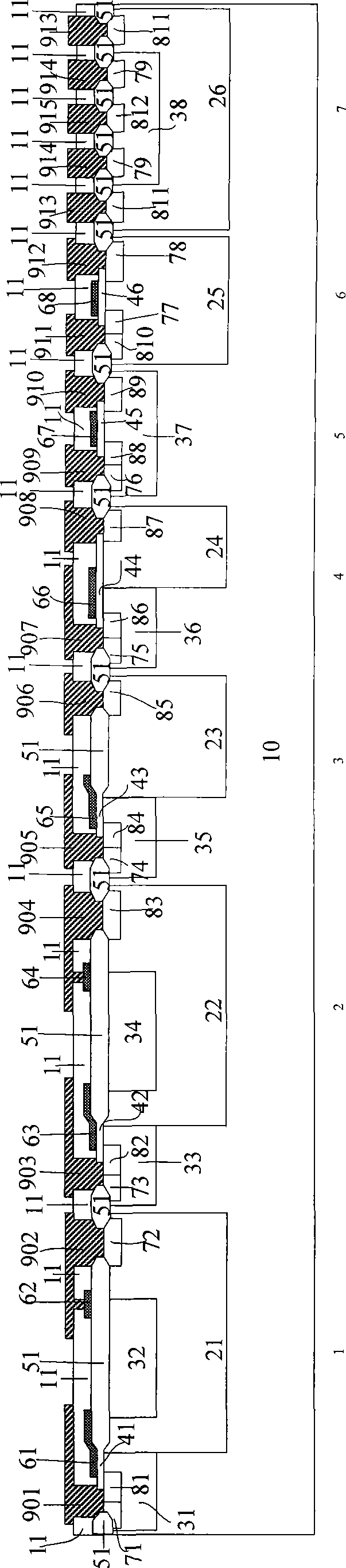

[0024] Referring to the accompanying drawings, it can be seen that the present invention provides a group of BCD semiconductor devices, which are directly fabricated on a single crystal substrate.

[0025]The high-voltage nLIGBT device 1 is directly made in the p-type substrate 10, 21 is the n-type drift region well of nLIGBT, 31 is the p-type body region of nLIGBT, 32 is the p-type falling field layer of nLIGBT, and 81 is the nLIGBT nLIGBT + Cathode area, 71 is the p of nLIGBT + Well contact area, 72 is the p of nLIGBT + Anode region, 51 is the field oxide layer of nLIGBT, 41 is the gate oxide layer of nLIGBT, 11 is the metal front dielectric of nLIGBT, 61 is the polysilicon gate of nLIGBT, 62 is the polysilicon field plate of nLIGBT, 901 is the cathode metal of nLIGBT, 902 It is the anode metal of nLIGBT. The p-type drop field layer 32 is located under the field oxide layer 51 and surrounded by the n-type drift region well 21, the p-type + The anode region 72 is under the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com