Thermally conductive thermoplastic adhesive composition

A composition and thermoplastic technology, applied in the direction of adhesive types, other rubber adhesives, polymer adhesive additives, etc., can solve the problems that cannot be said about heat resistance, sufficient retention, etc., and achieve excellent disassembly and high heat Conductivity, anti-static effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

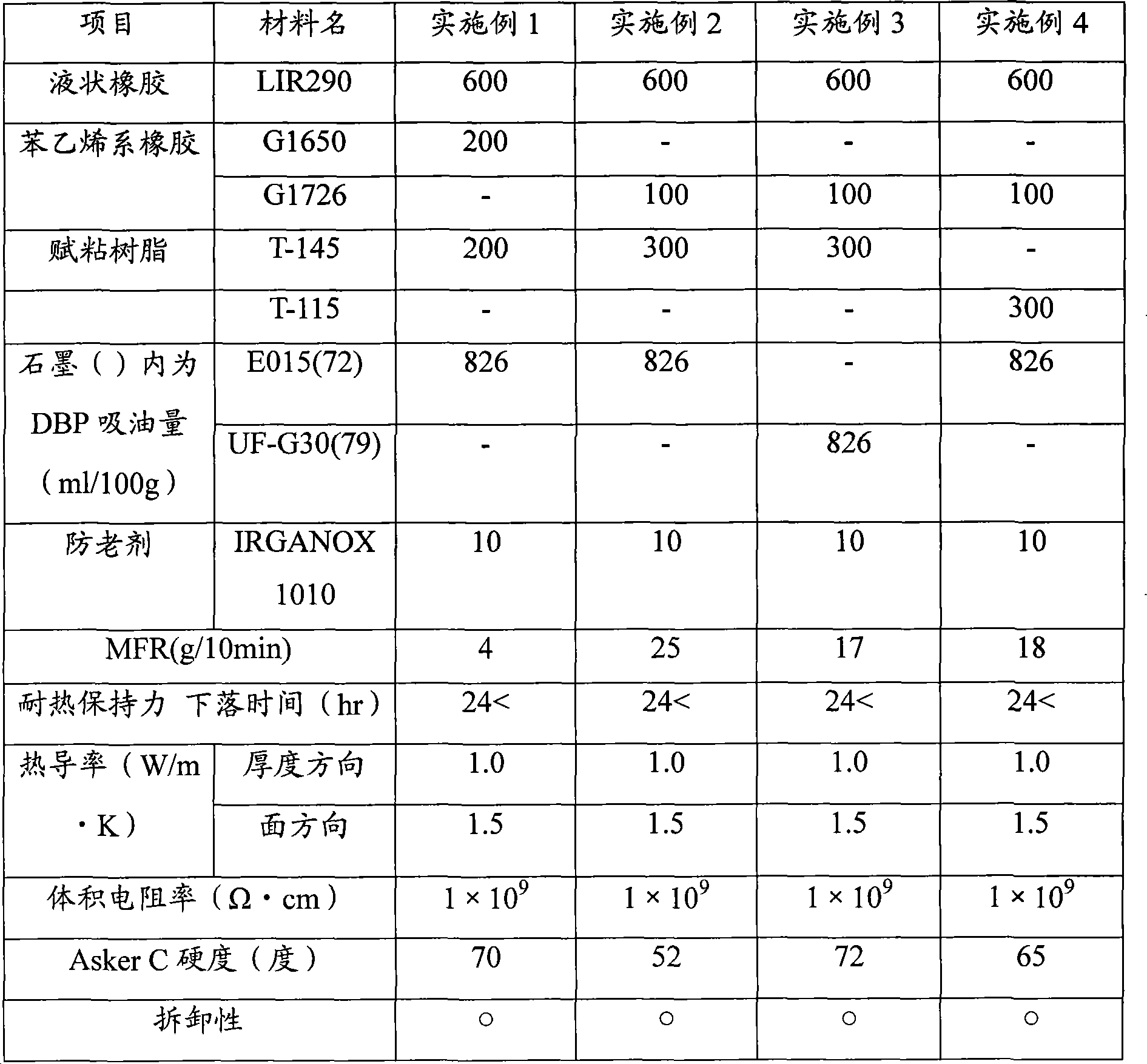

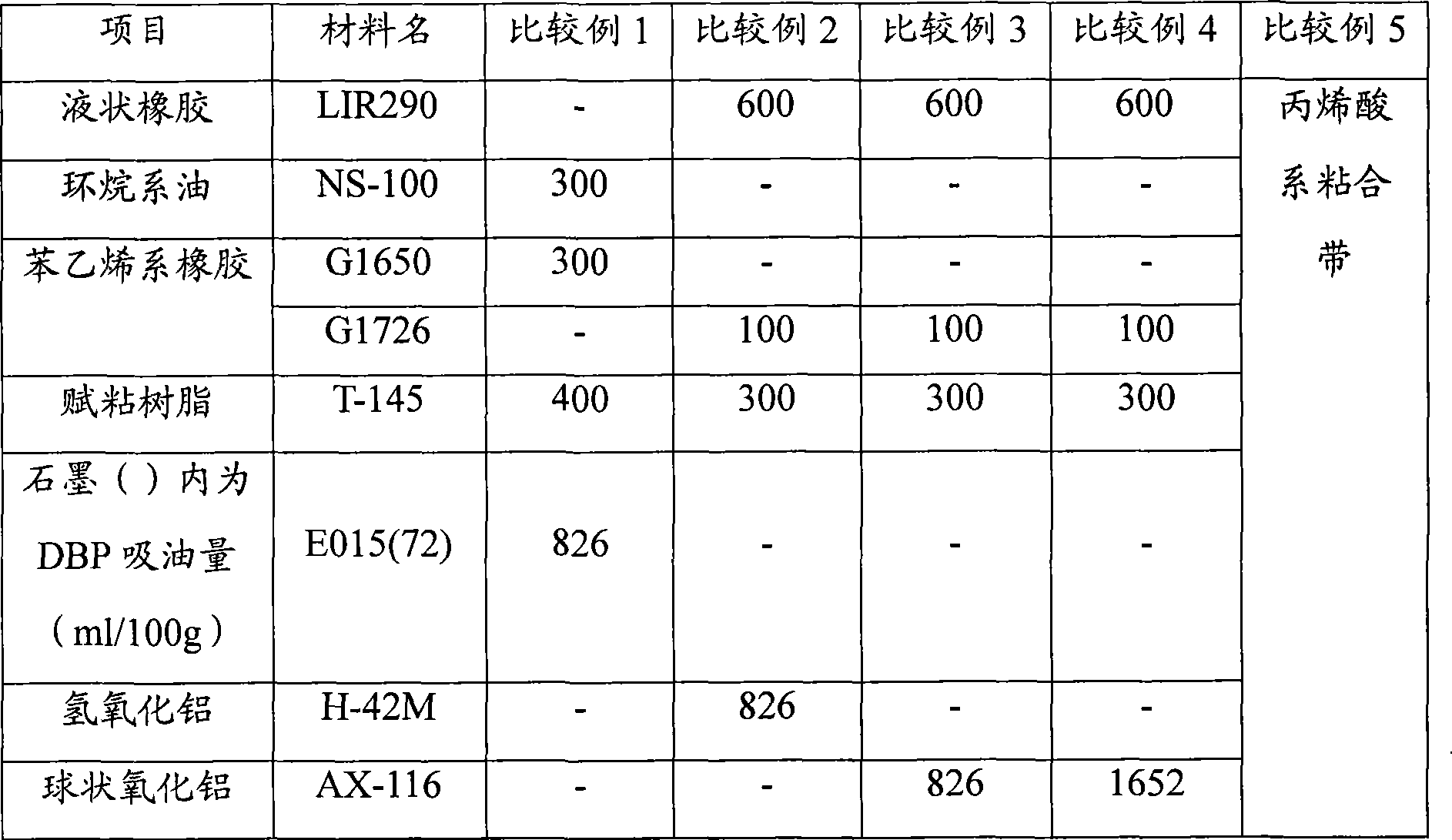

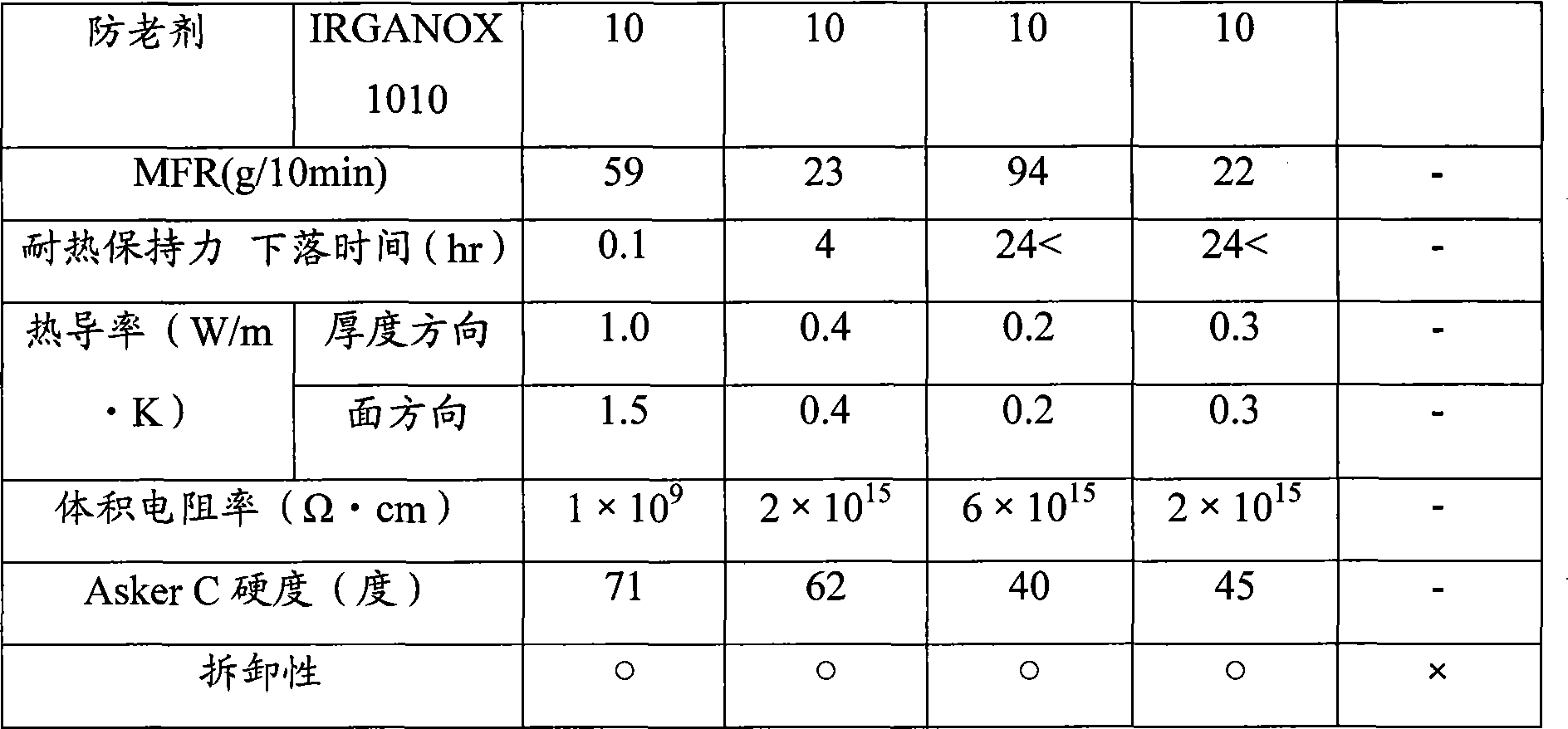

Embodiment 1

[0078] After preheating the heating kneader to 180°C, add 600 parts of KRAPRENE (trademark) LIR-290 (manufactured by Kuraray Co., Ltd., liquid hydrogenated polyisoprene rubber, weight average molecular weight 25,000, hydrogenation rate about 90%) as liquid rubber ), 200 parts of KRATON (trademark) G1650 (manufactured by KRATON Polymer Co., Ltd., SEBS, styrene / (ethylene·butylene) ratio = 29 / 71 mass ratio) as styrene rubber, 200 parts of Tackifying resin YS Polystar T145 (manufactured by YASUHARA CHEMICAL, terpene phenolic resin, softening point 145°C) and 10 parts of IRGANOX1010 (manufactured by Ciba Specialty Chemicals, hindered phenolic antioxidant) were mixed at 180°C for 4 hours, and each After the material was melted, 826 parts of E015 (manufactured by Chuetsu Graphite Industry Co., Ltd., artificial graphite, average particle diameter of about 135 μm and average aspect ratio of 3.4 as measured by laser diffraction method) were added as graphite, and further mixed at 180° C....

Embodiment 2

[0080] In addition to using 100 parts of KRATON (trademark) G1726 (manufactured by Kraton Polymer Co., Ltd., SEBS, styrene / (ethylene·butylene) ratio = 30 / 70 mass ratio, 70% diblock) as a styrene-based rubber, 300 Except for YS Polystar T145 as a tackifying resin, a thermally conductive thermoplastic adhesive composition having a graphite compounding amount of about 45% by mass was obtained in the same manner as in Example 1.

Embodiment 3

[0082] In addition to using UF-G30 (manufactured by Showa Denko Co., Ltd., artificial graphite, the average particle size measured by laser diffraction is about 10 μm, and the average aspect ratio is 3.6) as graphite instead of E015, the graphite compound was obtained in the same manner as in Example 2. A thermally conductive thermoplastic adhesive composition in an amount of about 45% by mass.

PUM

| Property | Measurement | Unit |

|---|---|---|

| oil absorption | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com