Intellectualized two shift-gears automatic speed-changing electric wheel hub

An electric wheel hub and automatic shifting technology, which is applied in the direction of electric components, electric power devices, electrical components, etc., can solve the problems of increasing the size of the transmission, short continuation distance, and small adaptation range, etc., to achieve small size and lightness, and improve power performance , the effect of improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

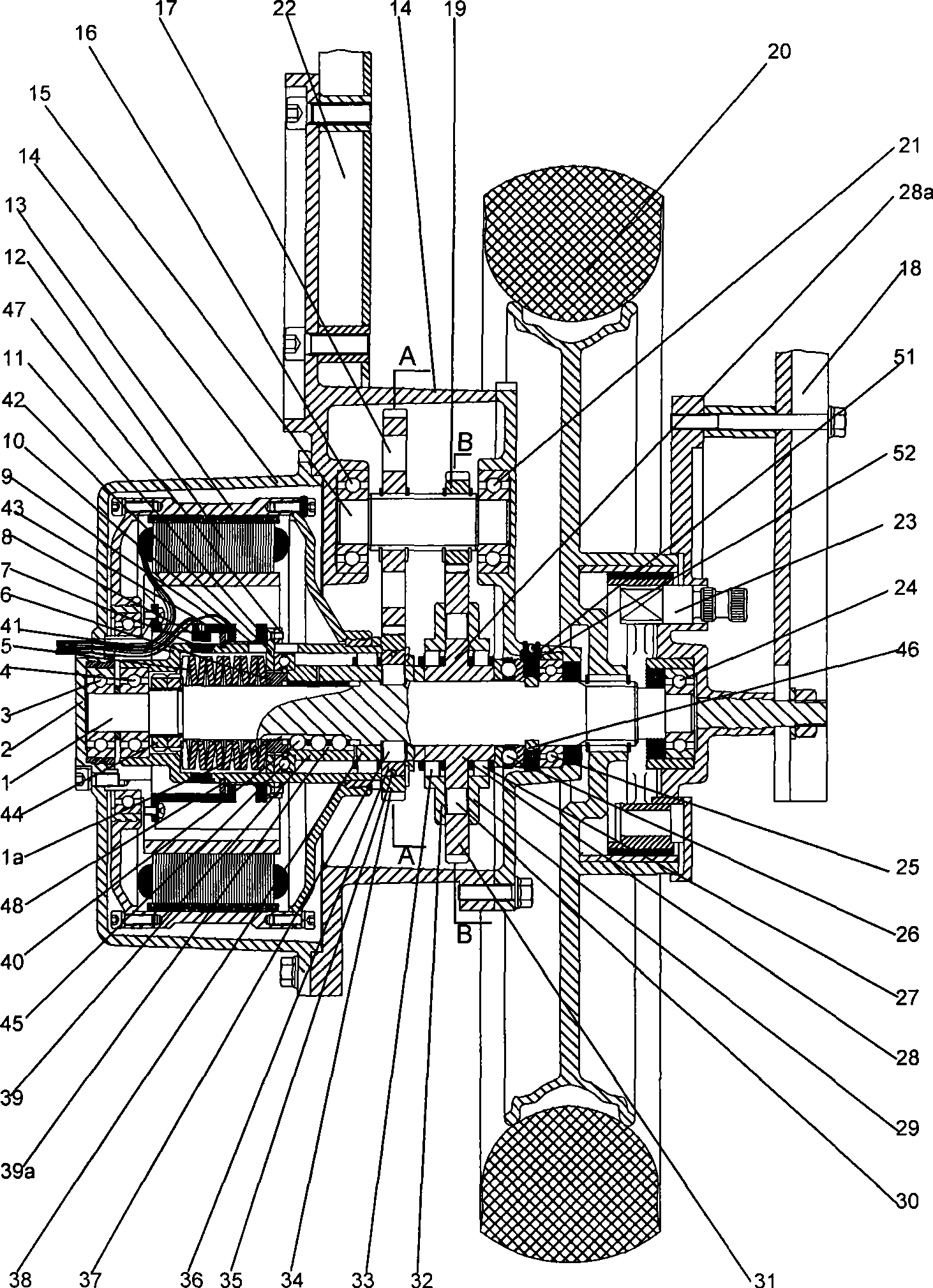

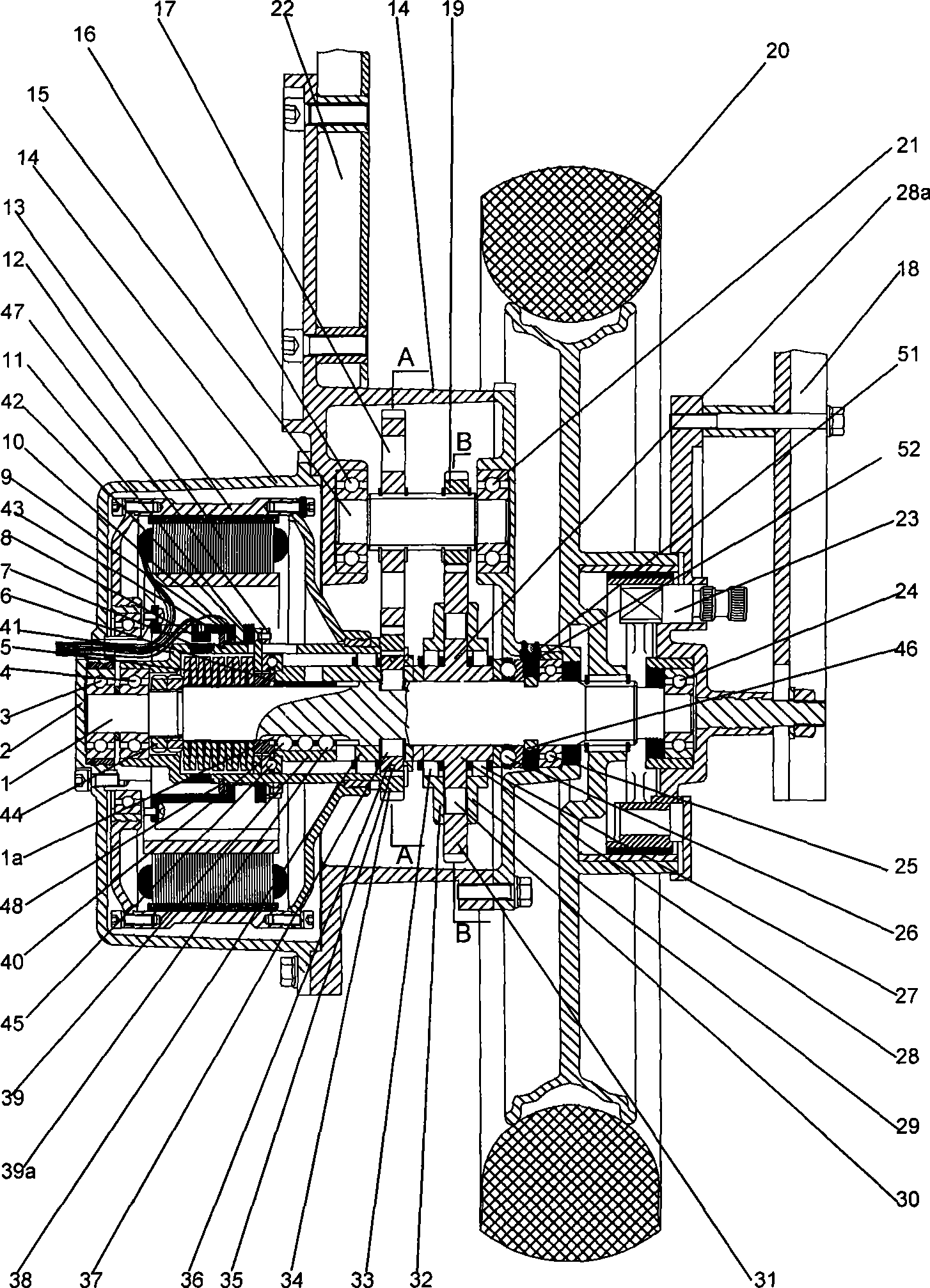

[0044] figure 1 It is a schematic diagram of the axial section structure of the present invention, as shown in the figure: the motor of this embodiment rotates counterclockwise when viewed from left to right, and the motor is an outer rotor motor.

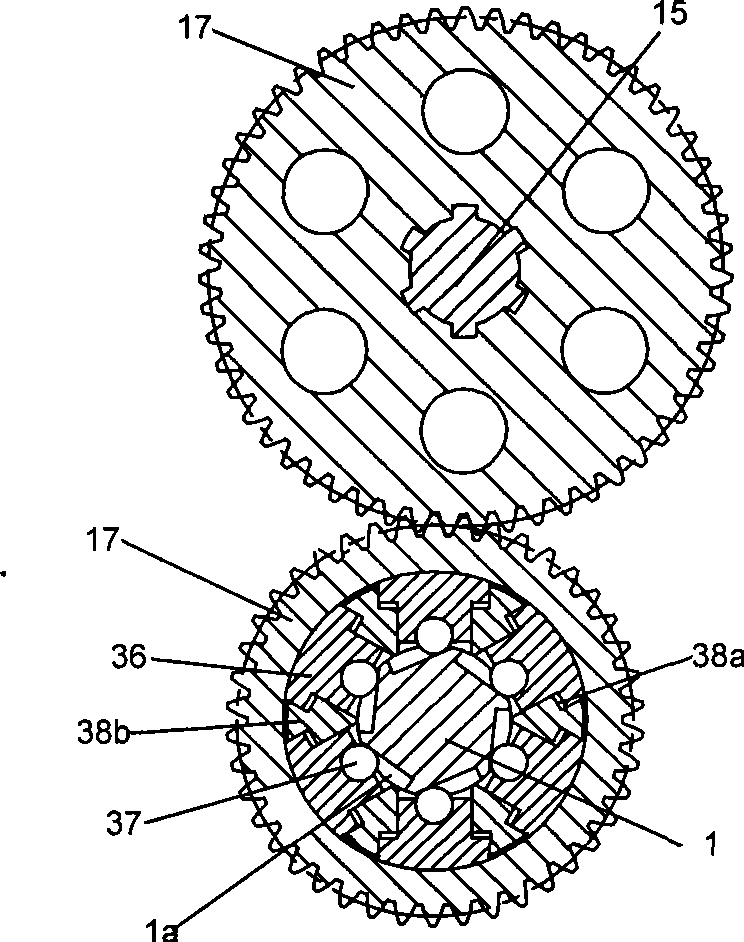

[0045] The intelligentized two-speed automatic variable speed electric hub comprises a left hub frame 22, a right hub frame 18, a casing 14, a motor, a drive shaft 1, a wheel 20 and a braking device 23 arranged on the drive shaft; the left hub frame 22 and The box body 14 is fixedly connected; the motor is located in the box body 14 and arranged on the outer circumference of the transmission shaft 1, and the motor stator 12 is relatively fixed with the box body 14; the transmission shaft 1 is arranged in the box body 14 through the first radial rolling bearing 3 and the fifth diameter To the rolling bearing 25 and its rotation fit; a part of the transmission shaft 1 extends out of the box body 14 and the wheel 20 is engaged and fix...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com