Pre-pressing horizontal refuse compressor

A garbage compression and garbage technology, which is applied in garbage conveying, garbage collection, storage devices, etc., can solve the problems of imperfect dehydration performance, incomplete dehydration, and unsatisfactory effect, so as to prevent secondary pollution, reduce garbage volume, Manpower saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

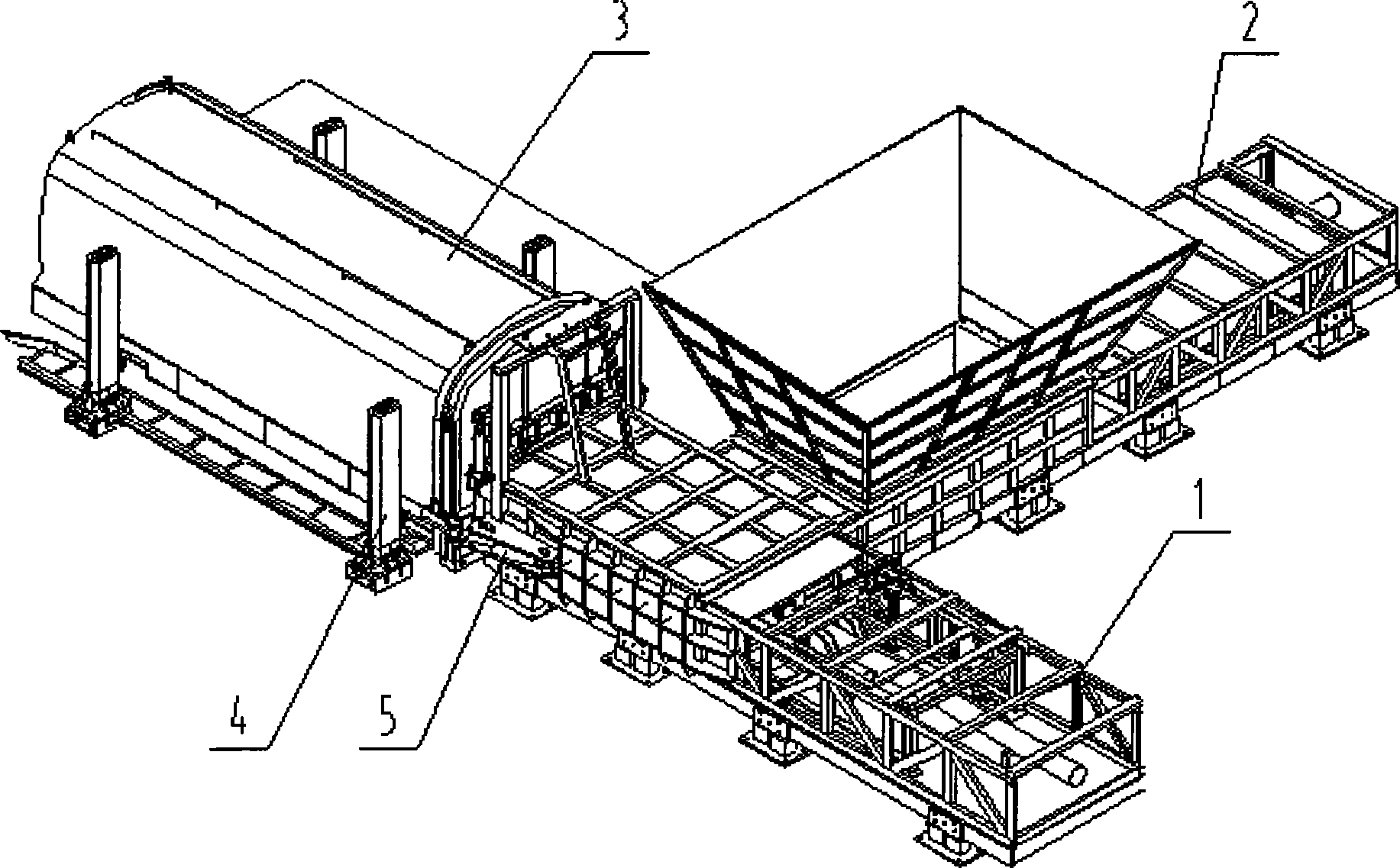

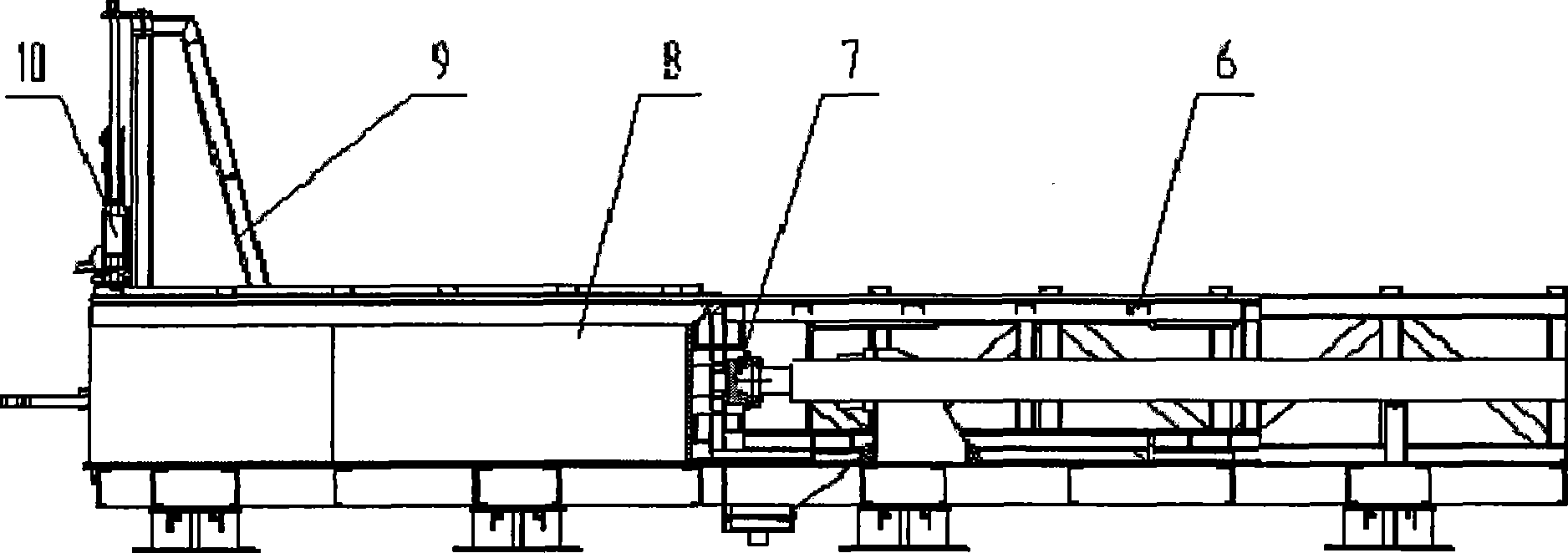

[0020] like figure 1 Shown: when the garbage needs to be collected, the garbage compartment 3 of the empty compressed garbage truck transported by the chassis of the car reverses and drives into the transfer station along the wheel guide device, stops when the wheel touches the tire limiter, turns off the power supply, and operates the hydraulic pressure The control system enables the lifting mechanism 4 to lift the garbage compartment 3 to the maximum height. The lifting mechanism 4 has four lifting towers, which are installed on the left and right sides of the garbage compartment 3 in front, rear, left, and right sides. The chassis of the car leaves the garbage collection position. Manipulate the hydraulic control system to make the lifting mechanism 4 lower the garbage compartment 3 into the garbage transfer station, close the locking mechanism 5 to make the garbage compartment 3 dock with the garbage outlet of the main compressor 1 and lock it, and operate the lifting cylin...

Embodiment 2

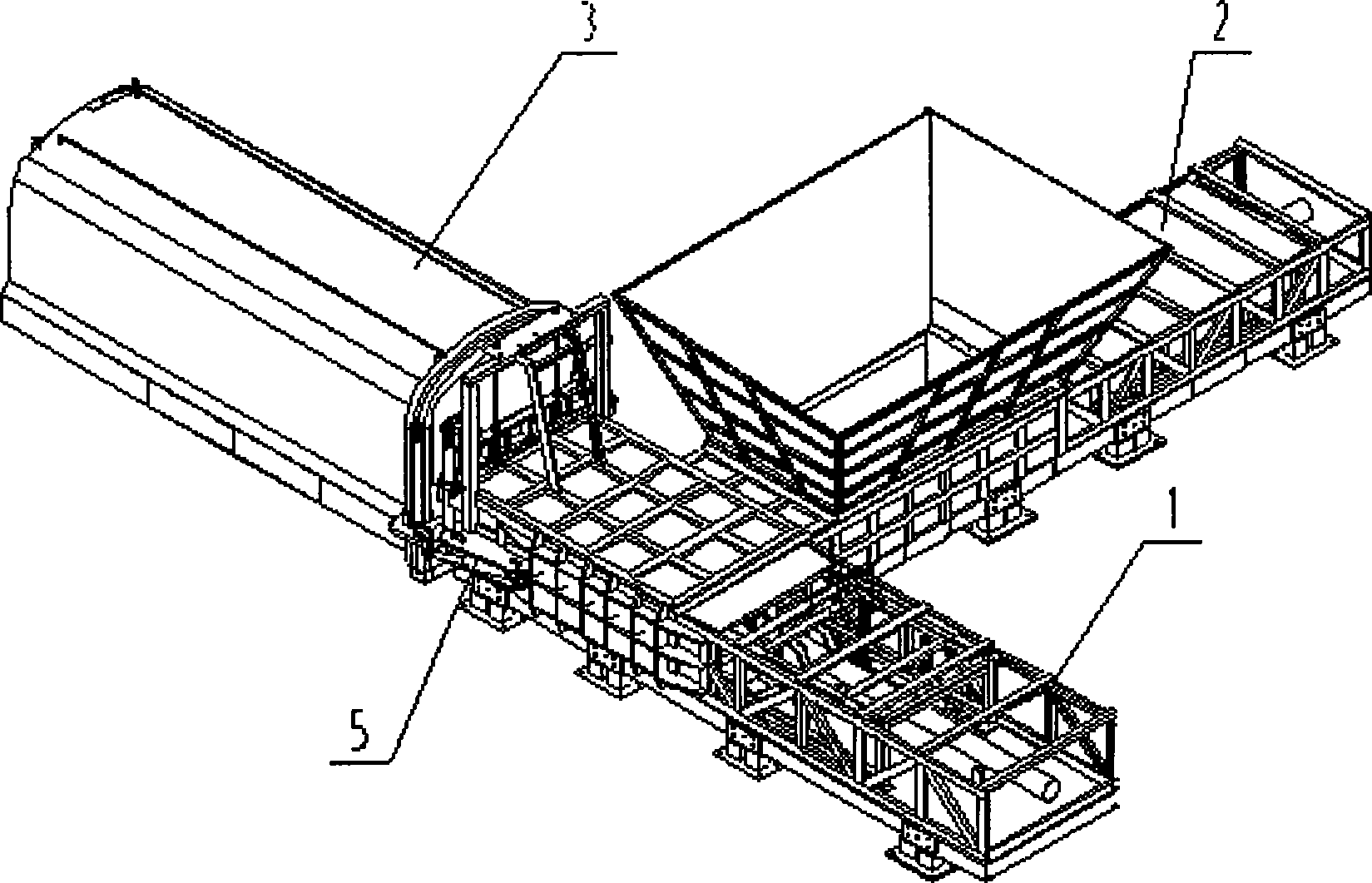

[0022] like figure 2 Shown: When the garbage needs to be collected, the chassis of the car transports the empty detachable compressed garbage compartment 3 and drives into the transfer station along the wheel guide device, stops when the wheel touches the tire limiter, and manipulates the detachable compressed garbage The pull arm mechanism of the car puts the car body on the car position; close the power supply, operate the hydraulic system, make the door of the garbage car 3 dock with the garbage outlet of the main compressor 1 and lock it, and open the lifting cylinder 10 so that the gate of the garbage car 3 Mention, at this moment, garbage truck (tricycle or post-loading compressed garbage truck, dump truck, etc.) can drive in from the car runway, stop at the unloading platform, and constantly dump the garbage, so that the garbage enters the secondary compressor from the loading hopper 14 In 2, the hydraulic system is operated, the auxiliary push head assembly 12 advance...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com