Method for preparing 4-propargyl nitrogen heterocyclic butyl-2-one and 4-allenyl nitrogen heterocyclic butyl-2-one

A technology of azetidine and propargyl nitrogen, applied in the field of preparing 4-propargyl azetidin-2-one and 4-alkenyl azetidin-2-one, which can solve unfavorable industrialization , complex operation and other issues, to achieve the effect of simple route, cheap and easy-to-obtain raw materials, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

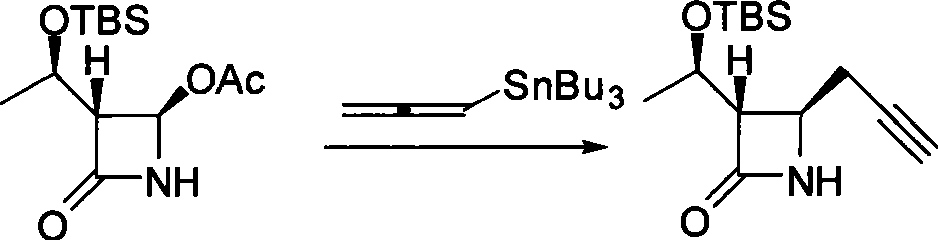

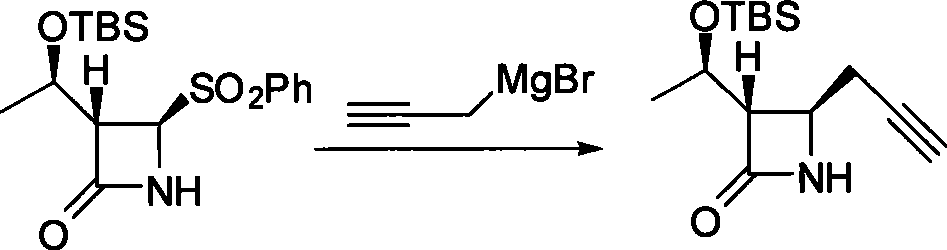

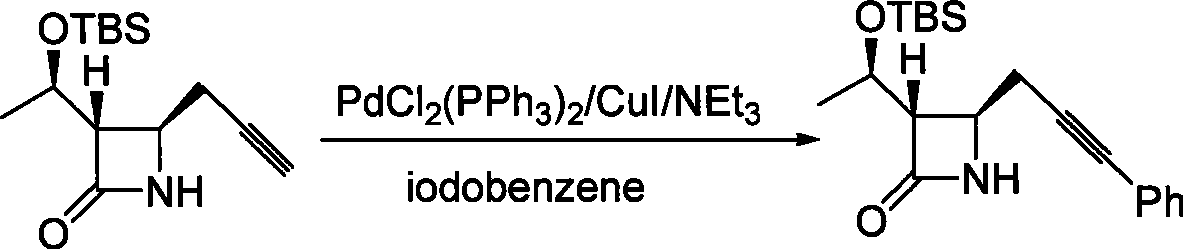

Method used

Image

Examples

Embodiment 1

[0028] Example 1 (3S, 4R)-3-((R)-1-(tert-butyldimethylsilyloxy)ethyl)-4-(2-propargyl)azetidin-2-one and (3S,4R)-3-((R)-1-(tert-butyldimethylsilyloxy)ethyl)-4-(1,2-alkenyl)azetidin-2-one Synthesis

[0029] (2R,3R)-3-((R)-1-(tert-butyldimethylsilyloxy)ethyl-4-acetylazetidin-2-one (115mg, 0.4mmol), zinc Powder (52mg, 0.8mmol) and propargyl bromide (1mmol) were added to 3mL tetrahydrofuran, heated, reacted for 6 hours, cooled to room temperature, quenched by adding water (8mL), extracted with ethyl acetate (10mL×2 times). The organic phases were combined, dried over anhydrous sodium sulfate and concentrated under reduced pressure. Post-treatment gave (3S, 4R)-3-((R)-1-(tert-butyldimethylsilyloxy)ethyl)-4-( 2-propargyl)azetidin-2-one, 79% yield. and (3S,4R)-3-((R)-1-(tert-butyldimethylsilyloxy)ethyl) -4-(1,2-Allenyl)azetidin-2-one, 2% yield.

Embodiment 2

[0030] Example 2 (3S, 4R)-3-((R)-1-(tert-butyldimethylsilyloxy)ethyl)-4-(2-propargyl)azetidin-2-one and (3S,4R)-3-((R)-1-(tert-butyldimethylsilyloxy)ethyl)-4-(1,2-alkenyl)azetidin-2-one Synthesis

[0031] (2R,3R)-3-((R)-1-(tert-butyldimethylsilyloxy)ethyl-4-acetylazetidin-2-one (115mg, 0.4mmol), zinc Powder (52mg, 0.8mmol) and propargyl chloride (1mmol) were added to 3mL diethyl ether, reacted at 0°C for 24 hours, raised to room temperature, quenched by adding water (10mL), and extracted with dichloromethane (10mL×2 times). The organic phases were combined, dried over anhydrous sodium sulfate and concentrated under reduced pressure. Post-treatment gave (3S, 4R)-3-((R)-1-(tert-butyldimethylsilyloxy)ethyl)-4-( 2-propargyl)azetidin-2-one, 54% yield. and (3S,4R)-3-((R)-1-(tert-butyldimethylsilyloxy)ethyl) -4-(1,2-Allenyl)azetidin-2-one, 2% yield.

Embodiment 3

[0032] Example 3 (3S, 4R)-3-((R)-1-(tert-butyldimethylsilyloxy)ethyl)-4-(2-propargyl)azetidin-2-one and (3S,4R)-3-((R)-1-(tert-butyldimethylsilyloxy)ethyl)-4-(1,2-alkenyl)azetidin-2-one Synthesis

[0033](2R,3R)-3-((R)-1-(tert-butyldimethylsilyloxy)ethyl-4-benzoylazetidin-2-one (145mg, 0.4mmol), Ketone powder (51.2 mg, 0.8 mmol) and propargyl fluoride (1 mmol) were added to 3 mL of toluene, heated to reflux, reacted for 6 hours, cooled to room temperature, quenched by adding water (8 mL), extracted with ether (10 mL×2 times ). The combined organic phases were dried over anhydrous sodium sulfate and concentrated under reduced pressure. Post-processing gave (3S, 4R)-3-((R)-1-(tert-butyldimethylsilyloxy) ethyl)-4 -(2-propargyl)azetidin-2-one, yield 8%. and (3S,4R)-3-((R)-1-(tert-butyldimethylsilyloxy)ethyl yl)-4-(1,2-alkenyl)azetidin-2-one, 2% yield.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com