Organosilane modified bisphenol A cyanate ester resin and preparation method thereof

A technology of organosilane and type cyanate, which is applied in the field of organosilane-modified bisphenol A type cyanate resin and its preparation, can solve problems that have not been seen, and achieve small molecular weight, excellent thermal performance, and dielectric constant Increased effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

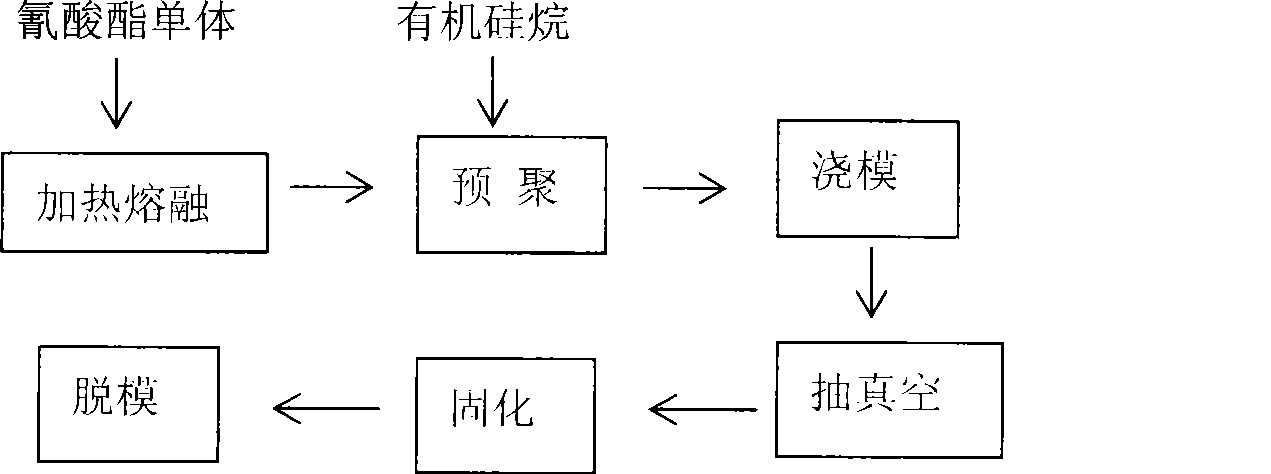

Method used

Image

Examples

Embodiment 1

[0025] Heat and melt 100 parts of bisphenol A type cyanate, then add 5 parts of γ-(2,3 glycidoxy)propyltrimethoxysilane, heat and stir, and carry out prepolymerization at 80-120°C. Polymerization time is 10-50 minutes. Then pour it into the preheated mold, vacuumize to remove air bubbles, put it into an oven to cure according to a certain curing process, the curing temperature is 100-220 ° C, and the curing time is 6-12 hours, that is, the organosilane modified Bisphenol A type cyanate resin.

Embodiment 2

[0027] Heat and melt 100 parts of bisphenol A cyanate, then add 5 parts of γ-aminopropyltriethoxysilane, heat and stir, and perform prepolymerization at 80-120°C for 10-50 minutes. Then pour it into the preheated mold, vacuumize to remove air bubbles, put it in an oven to cure according to a certain curing process, the curing temperature is 100-220 ° C, and the curing time is 6-12 hours, that is, the organic silane modified Bisphenol A type cyanate resin.

Embodiment 3

[0029] Heat and melt 100 parts of bisphenol A cyanate, then add 5 parts of N-β(aminoethyl)-γ-aminopropyltrimethoxysilane, heat and stir, and prepolymerize at 80-120°C. The prepolymerization time is 10 to 50 minutes. Then pour it into the preheated mold, vacuumize to remove air bubbles, put it in an oven to cure according to a certain curing process, the curing temperature is 100-220 ° C, and the curing time is 6-12 hours, that is, the organic silane modified Bisphenol A type cyanate resin.

[0030] This patent uses organosilane to modify bisphenol A cyanate resin, and the active end groups such as epoxy groups and amino groups at the end of the organosilane chain react with the cyano group in the cyanate monomer to modify the bisphenol A cyanate resin. Introducing silicone segments. It can not only improve the compatibility between organosilane and cyanate resin, but also reduce the crosslinking density of cyanate resin, so that the modified system can improve its impact str...

PUM

| Property | Measurement | Unit |

|---|---|---|

| impact strength | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

| thermal decomposition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com