Method for producing stainless steel tap

A manufacturing method and faucet technology, which are applied in the directions of manufacturing tools, valve details, valve shell structure, etc., can solve the problems of complex cavity structure and thin-walled articles, complex stainless steel faucet cavity, etc., so as to save stainless steel materials and prevent complex cavity. and wall, the effect of cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

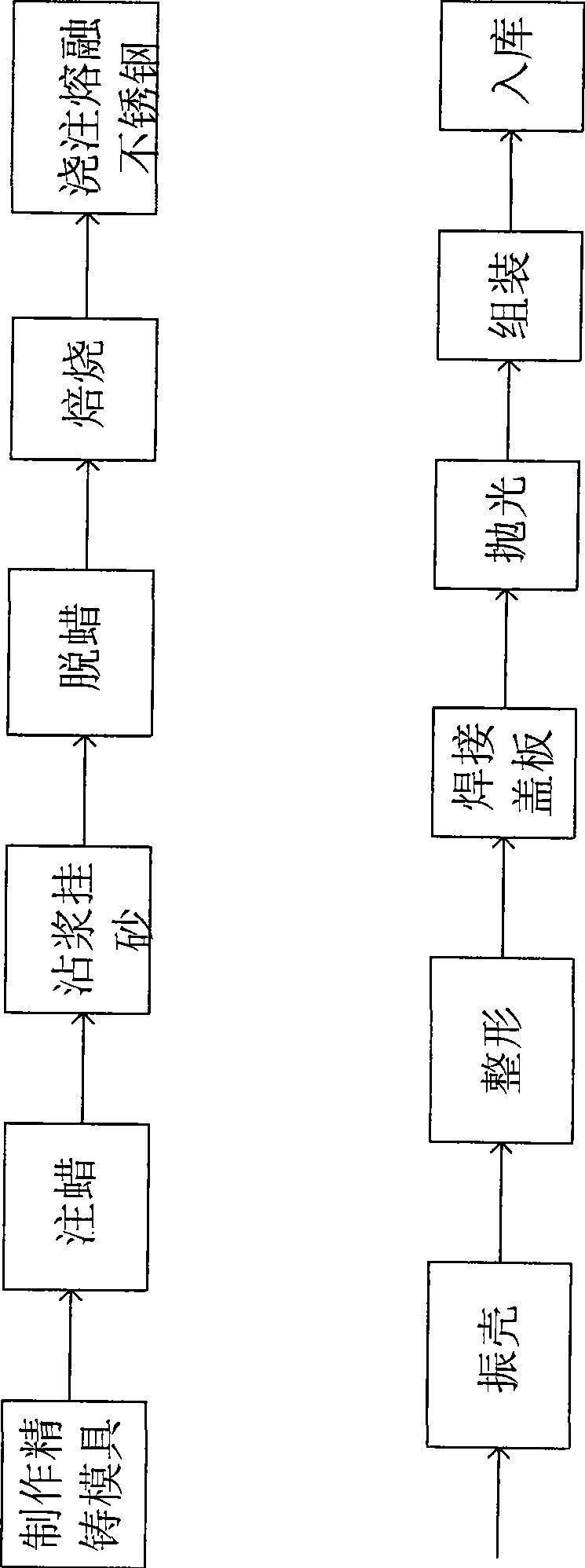

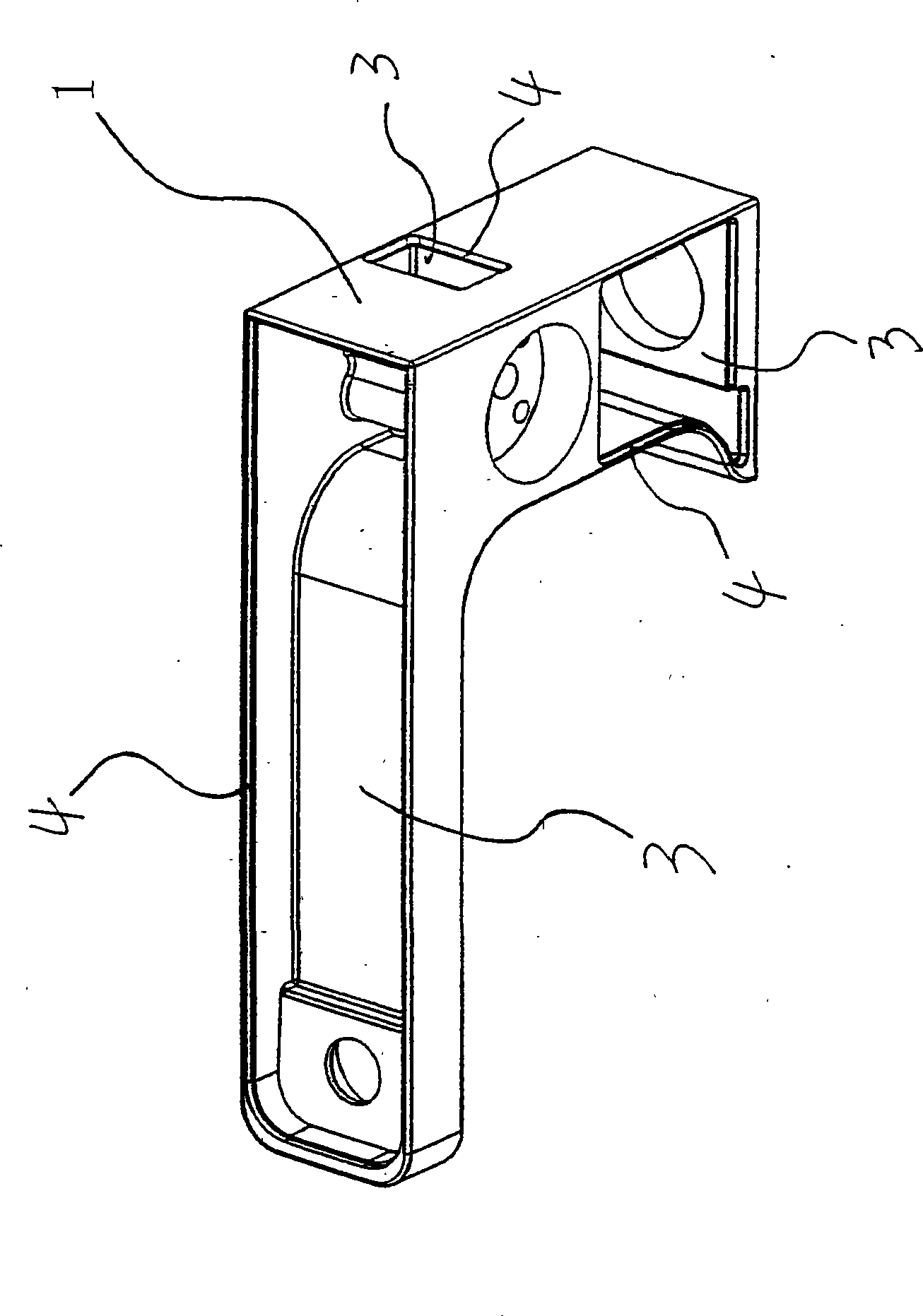

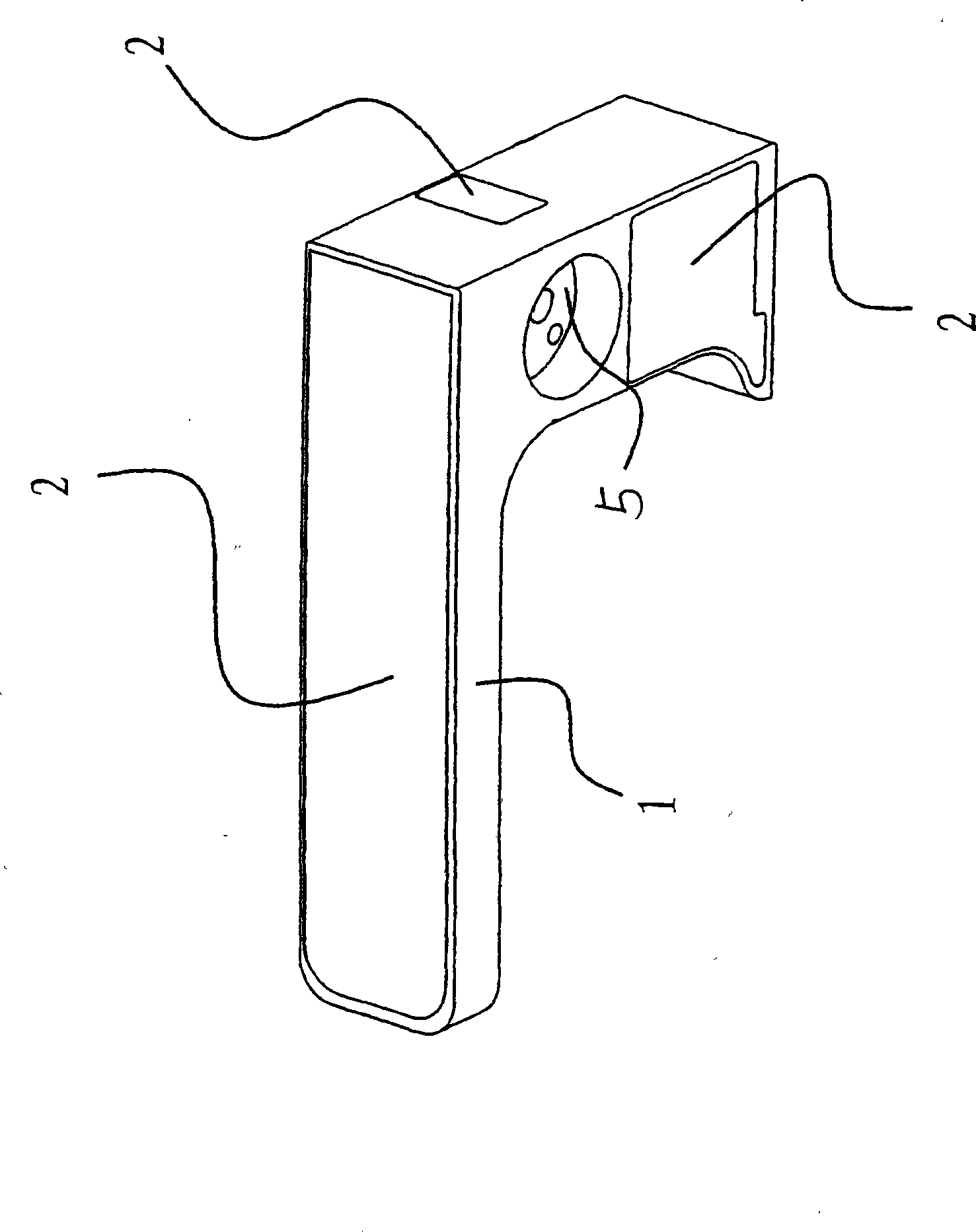

[0037] The present invention will be described below in conjunction with the accompanying drawings. figure 1 For the process flow chart of making stainless steel faucet of the present invention, figure 2 It is a structural schematic diagram after making the valve body blank of the present invention, image 3 It is the structural representation of the stainless steel faucet valve body behind the welding cover plate of the present invention, Figure 4 It is a structural schematic diagram of the polished and assembled stainless steel faucet of the present invention. figure 2 , 3 , 4. The faucet blank and the pipeline of the faucet expressed in 4 are all square, and of course the present invention is also applicable to the round shape. The precision casting molds described below are made of imported aluminum and / or iron and copper materials, and are processed in the machining center after the mold design is carried out using three-dimensional drawings. , storage.

[0038] W...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com