Method for producing p-cymene by continuous production and apparatus thereof

A technology for cymene and gasifier, applied in chemical instruments and methods, chemical recovery, organic chemistry, etc., can solve the problems of incapable of continuous industrialized production, small reaction scale, complicated processing process, etc., and achieve high equipment utilization rate , The effect of complete response and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

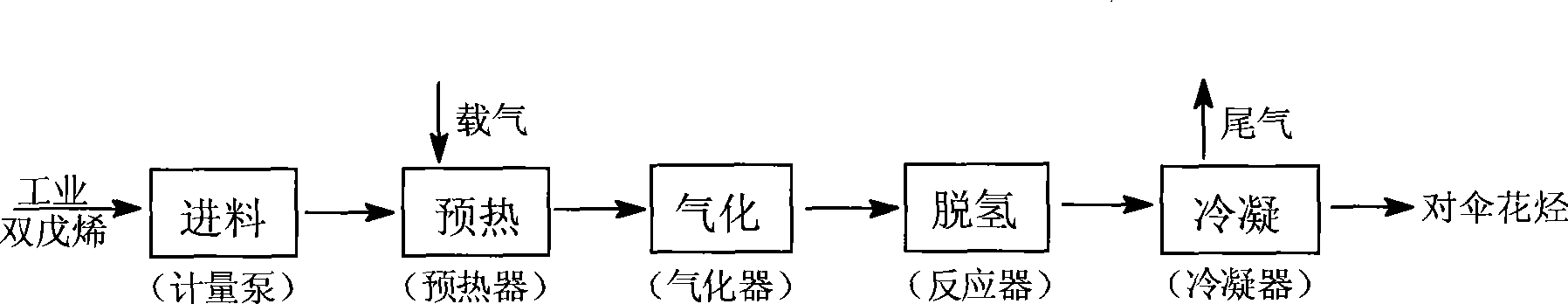

[0020] A method for continuous production of p-cymene from industrial dipentene, which uses industrial dipentene as a raw material, uses Pd / C as a catalyst, and undergoes a catalytic dehydrogenation reaction in a continuous reaction device to continuously produce p-cymene hydrocarbon method. like figure 1 As shown, it specifically includes the following steps:

[0021] Step 1: Add 0.1kg to 50.0kg of catalyst into the reactor, feed inert carrier gas nitrogen at a rate of 0.01L / min to 5.00L / min, turn on the heating device, and when the temperature of the reactor reaches 150°C to 400°C, Turn on the metering pump, and press the equivalent air speed of 0.5h -1 ~5.0h -1 The speed is continuously fed into the industrial dipentene raw material, preheated, gasified, and contacted with the catalyst for reaction. The above-mentioned catalyst is a Pd / C catalyst, and its palladium content is between 0.1% and 10.0%. Control the reactor temperature to be 150°C, 160°C, 170°C, 180°C, 190°...

Embodiment 2

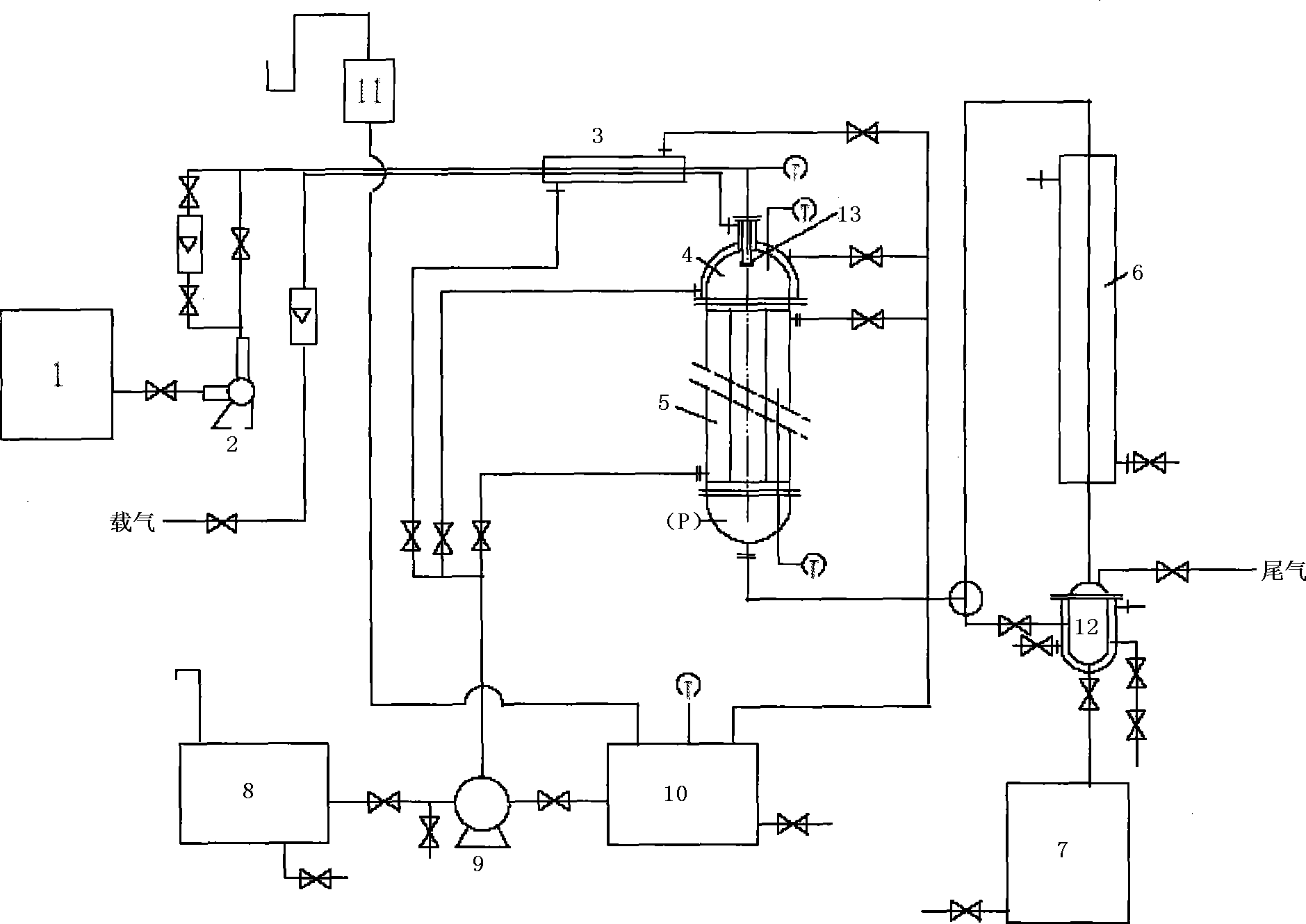

[0024] The device for implementing the above-mentioned production method described in the present invention, such as figure 2 Shown: It is mainly composed of raw material storage tank 1, metering pump 2, preheater 3, vaporizer 4, reactor 5, condenser 6, product storage tank 7 and heating device, in the preheater 3 and raw material storage tank 1 is provided with a metering pump 2 capable of continuous constant flow feeding, and the inlet of the metering pump 2 is connected with the outlet of the raw material storage tank 1, the outlet of the metering pump 2 is connected with the inlet of the preheater 3, and then the outlet of the preheater 3 is connected with the gas The inlet of the vaporizer 4 is connected, the outlet of the vaporizer 4 is connected with the inlet of the top of the reactor 5, the outlet of the bottom of the reactor 5 is connected with the inlet of the condenser 6, the outlet of the condenser 6 is connected with the inlet of the product storage tank 7, the h...

Embodiment 3~5

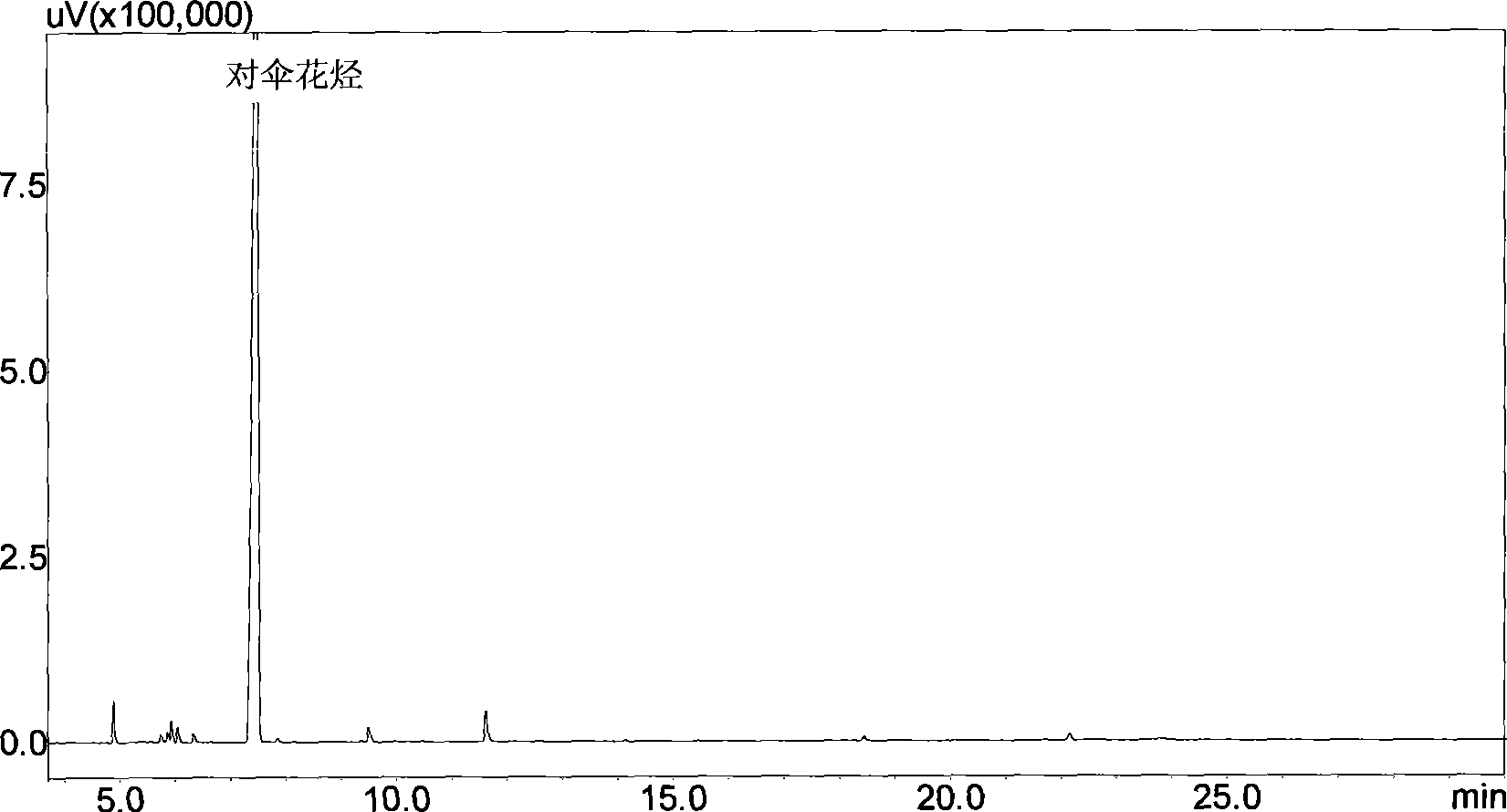

[0027] Operation steps for the continuous production of p-cymene from industrial dipentene at a temperature of 260°C:

[0028] The operation steps are the same as in Example 1, except that the temperature of the reactor is controlled at 260°C, and the nitrogen flow rates are respectively set to 0.01L / min, 0.10L / min, 1.00L / min, 1.50L / min, 2.00L / min, 3.00 The feed rate of L / min, 4.00L / min or 5.00L / min and raw material is equivalent to the space velocity of 0.5h -1 ~5.0h -1 . When the reaction conditions are stable, samples are taken for chromatographic analysis, and the p-cymene content in the product is 87% to 89%. The ratio of product outlet quality to raw material inlet quality is between 0.97 and 1.00.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com