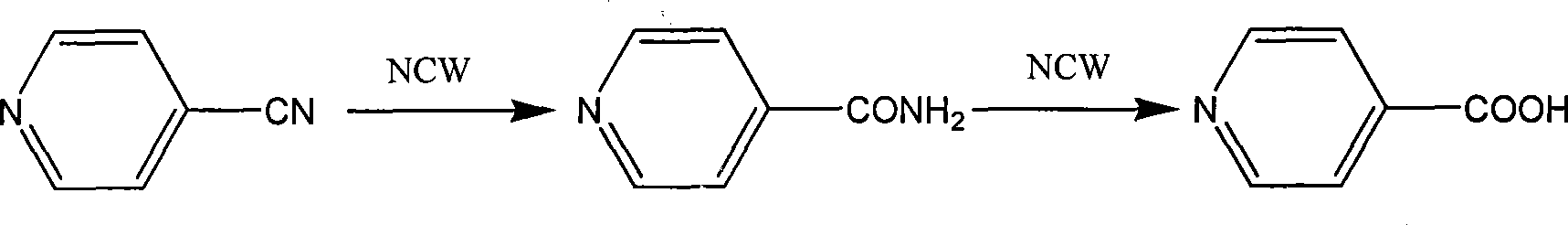

Method for preparing isonicotinic acid by non-catalytic hydrolyzing isonicotinonitrile in near-critical water medium

A near-critical water and catalytic hydrolysis technology, applied in the field of carboxylic acids, can solve problems such as complex process, increased equipment investment, environmental pollution, etc., and achieve the effects of solving pollution problems, high product purity and yield, and simple reaction process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

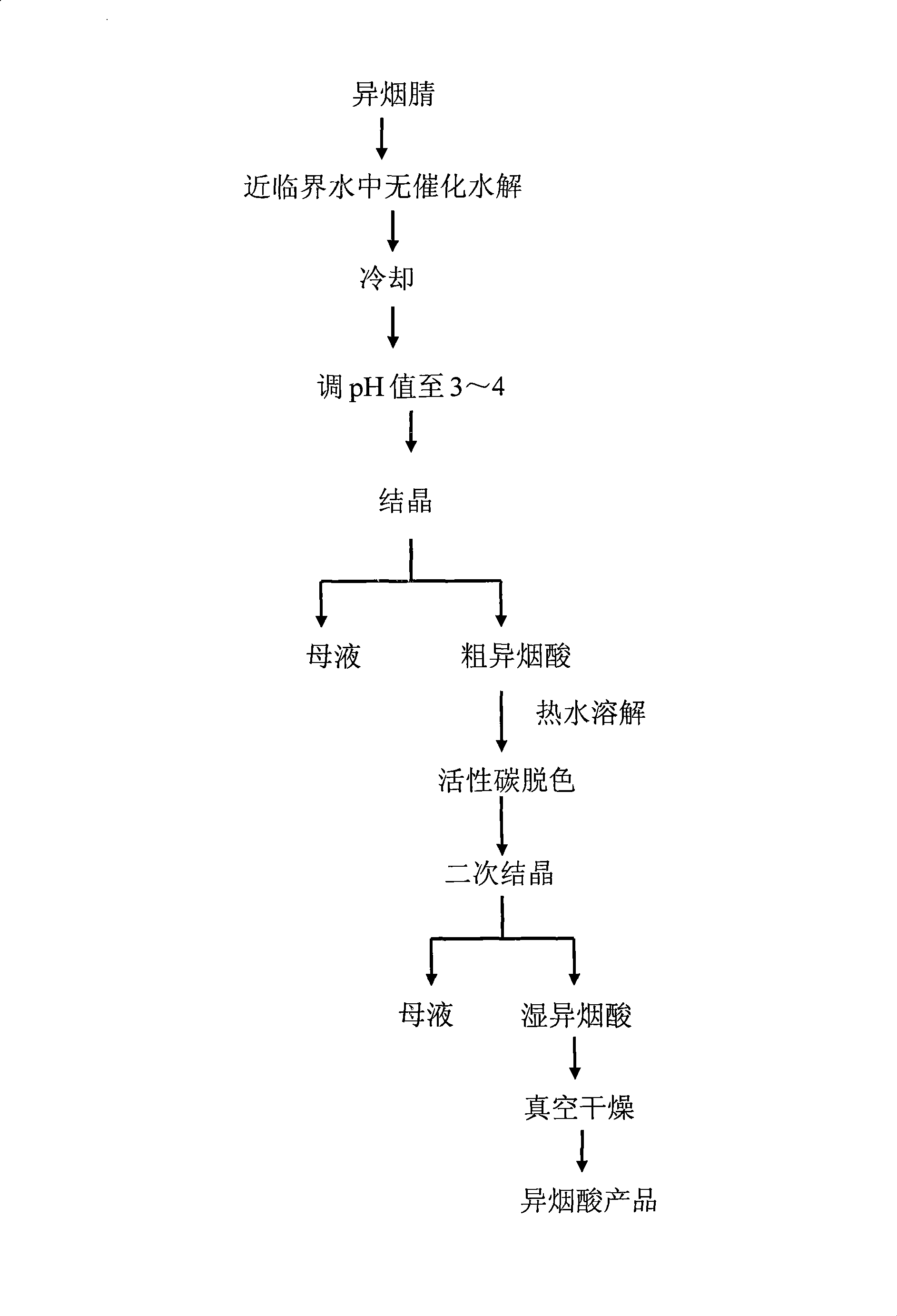

Embodiment 1

[0027] Add 300g of deionized water and 150g of isonicotonitrile (the mass ratio of deionized water to isoniazid is 2:1) in a 500mL intermittent autoclave, start stirring, heat up to boiling under normal pressure, open the exhaust valve for 5min, Use water vapor to remove the air in the kettle; close the exhaust valve, continue to heat up to 200°C for 600 minutes; add HCl solution to adjust the pH value to 3-4 after the reaction product is cooled, and obtain crude isonicotinic acid after crystallization. The crude isonicotinic acid product was dissolved in hot water, decolorized by activated carbon, secondary crystallized, and dried in vacuum to obtain 133.5 g of isonicotinic acid product. The purity of the product was 98.1% (wt%) analyzed by HPLC, and the yield was 73.8%.

Embodiment 2

[0029] Add 360g of deionized water and 120g of isonicotonitrile (mass ratio of deionized water to isonicotonitrile is 3:1) in a 500mL intermittent autoclave, start stirring, heat up to boiling under normal pressure, open the exhaust valve for 4min, Use steam to remove the air in the kettle; close the exhaust valve, continue to heat up to 210 ° C for 550 minutes; add H after the reaction product is cooled 2 SO 4 The pH value of the solution was adjusted to 3-4, and the crude product of isonicotinic acid was obtained after crystallization. The crude isonicotinic acid product was dissolved in hot water, decolorized by activated carbon, secondary crystallized, and dried in vacuum to obtain 110.1 g of isonicotinic acid product, which was analyzed by HPLC with a purity of 98.2% (wt%) and a yield of 76.2%.

Embodiment 3

[0031] Add 320g of deionized water and 80g of isonicotonitrile (mass ratio of deionized water to isonicotonitrile is 4:1) in a 500mL intermittent autoclave, start stirring, heat up to boiling under normal pressure, open the exhaust valve for 3min, Use water vapor to remove the air in the kettle; close the exhaust valve, continue to heat up to 220°C and react for 500 minutes; add HCl solution to adjust the pH value to 3-4 after the reaction product is cooled, and obtain crude isonicotinic acid after crystallization. The crude isonicotinic acid product was dissolved in hot water, decolorized by activated carbon, secondary crystallized, and vacuum dried to obtain 76.0 g of isonicotinic acid product. The purity of the product was 98.8% (wt%) analyzed by HPLC, and the yield was 79.3%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com