Culture medium for producing benzoylformic acid by fermentation method

A technology of acetophenone and culture medium, applied in the direction of fermentation, etc., can solve the problems of molecular shape influence, low biomass, substrate concentration and conversion rate can not continue to increase, and achieve the effect of convenient operation and high reaction specificity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

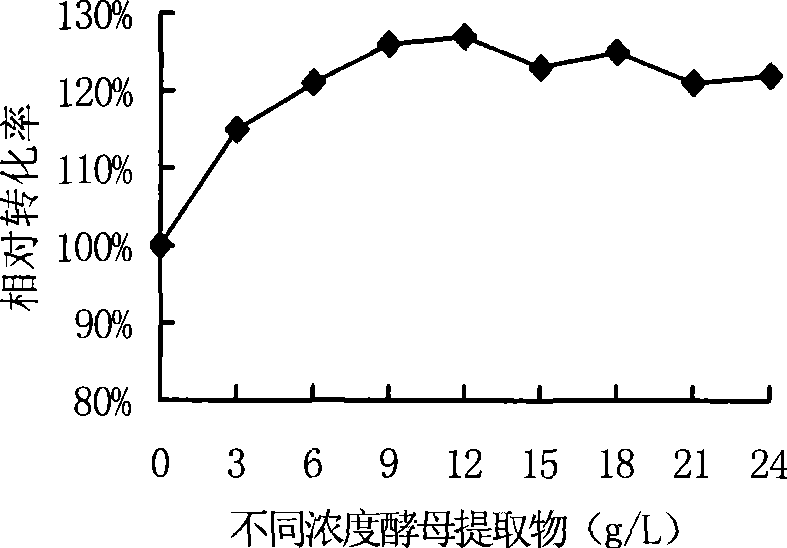

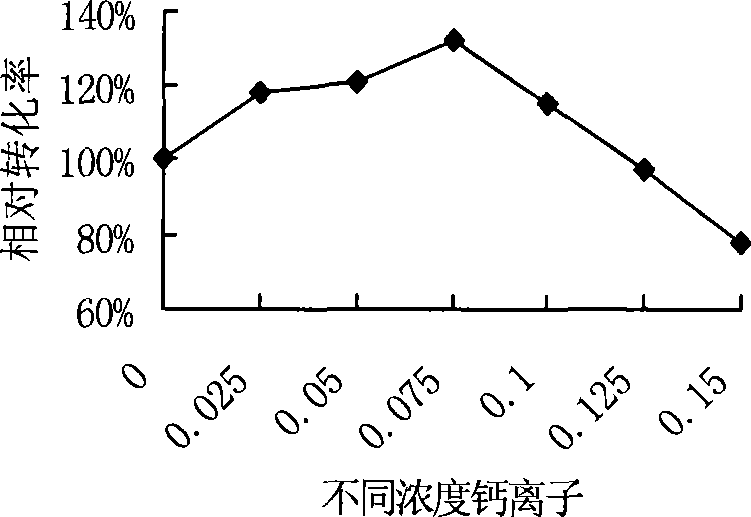

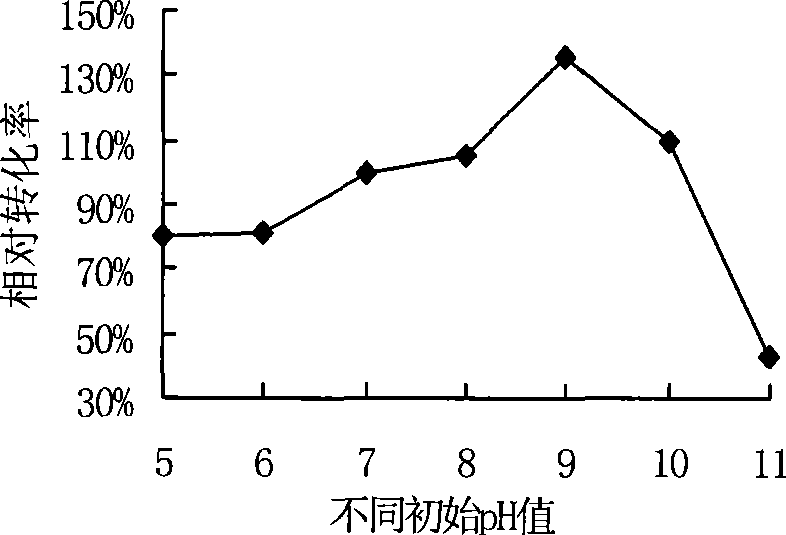

Method used

Image

Examples

Embodiment 1

[0028] Candida lipolytica SIPI0201 bacterial classification was inoculated in 25ml seed medium (glucose 3wt%, yeast extract 0.3wt%,, peptone 0.3wt%, K 2 HPO 4 ·3H 2 O 0.1wt%, MgSO 4 ·7H 2(0.05wt%, KCl 0.05wt%, natural pH), 30 ℃, 230r / min aerobic culture 20h, obtain seed liquid, then insert 25ml fermentation medium (fructose 0.2wt%, peptone 0.7 wt%, (NH 4 ) 2 SO 4 0.1wt%, KH 2 PO 4 0.4wt%, yeast extract 0.3wt%, calcium chloride 0.0003wt%, D, L-phenylglycine 2wt%, adjust the pH value to 8.0 with NaOH), aerobic culture under the same conditions for 6 days, HPLC analysis of acetophenone The yield was 35.9%.

Embodiment 2

[0030] Candida lipolytica SIPI0201 bacterial classification was inoculated in 25ml seed medium (glucose 3wt%, yeast extract 0.3wt%,, peptone 0.3wt%, K 2 HPO 4 ·3H 2 O 0.1wt%, MgSO 4 ·7H 2 (0.05wt%, KCl 0.05wt%, natural pH), 30 ℃, 230r / min aerobic culture 20h, obtain seed liquid, then insert 25ml fermentation medium (fructose 0.2wt%, peptone 0.7 wt%, (NH 4 ) 2 SO 4 0.1wt%, KH 2 PO 4 0.4wt%, yeast extract 1.2wt%, calcium chloride 0.005wt%, D, L-phenylglycine 2wt%, adjust the pH value to 7.5 with NaOH), aerobic culture under the same conditions for 6 days, HPLC analysis of acetophenone The yield was 39.5%.

Embodiment 3

[0032] Candida lipolytica SIPI0201 bacterial classification was inoculated in 25ml seed medium (glucose 3wt%, yeast extract 0.3wt%,, peptone 0.3wt%, K 2 HPO 4 ·3H 2 O 0.1wt%, MgSO 4 ·7H 2 (0.05wt%, KCl 0.05wt%, natural pH), 30 ℃, 230r / min aerobic culture 20h, obtain seed liquid, then insert 25ml fermentation medium (fructose 0.2wt%, peptone 0.7 wt%, (NH 4 ) 2 SO 4 0.1wt%, KH 2 PO 4 0.4wt%, yeast extract 2.4wt%, calcium chloride 0.005wt%, D, L-phenylglycine 2wt%, adjust the pH value to 8.0 with NaOH), aerobic culture under the same conditions for 6 days, HPLC analysis of acetophenone The yield was 37.7%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com