Method for preparing bulk nano/superfine crystal grain magnesium alloy by twinning deformation

A technology of twinning deformation and ultra-fine grains, which is applied in the field of preparing bulk nano/ultrafine-grain magnesium alloys by twinning deformation, can solve the problems of poor strain accumulation effect, uncontrolled recrystallization, and difficulty in scale, and achieves convenient operation. , suppress the dynamic reply, avoid the effect of reply

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

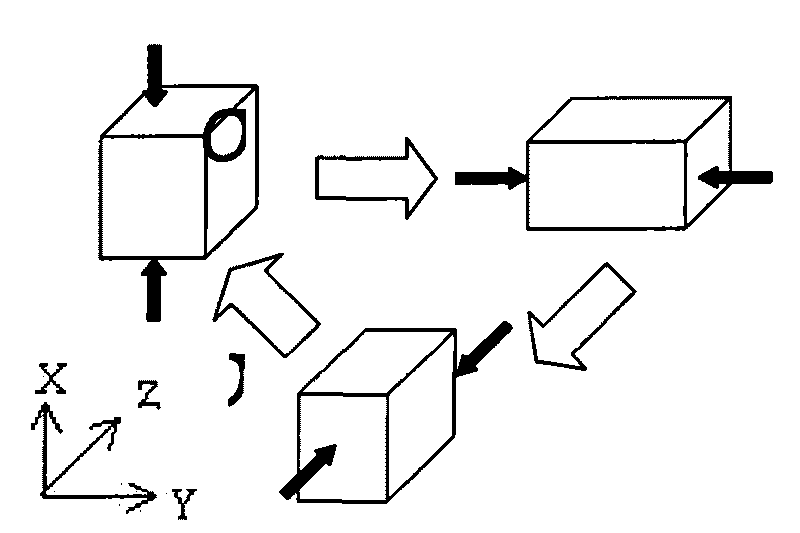

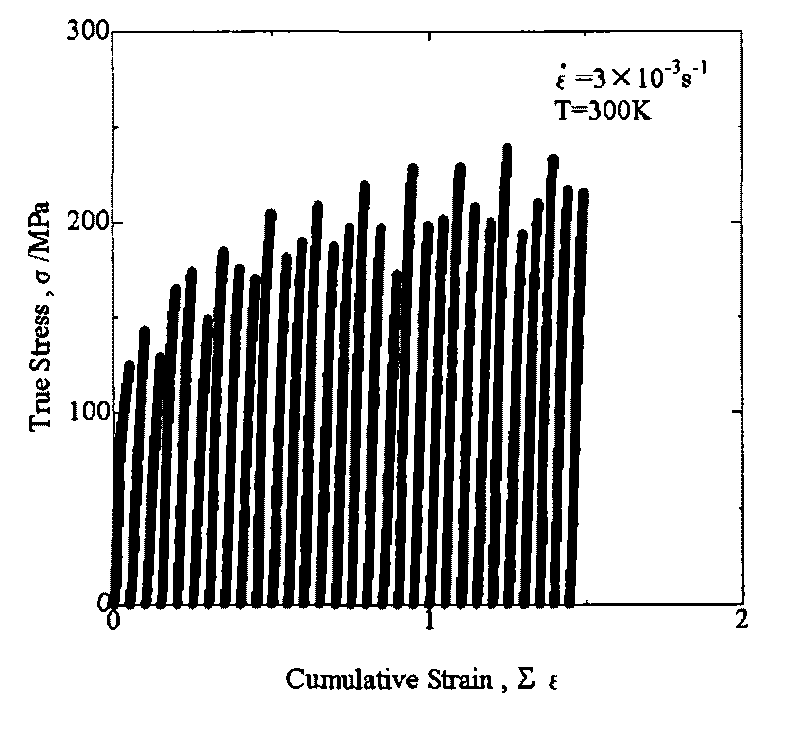

[0037] Cut the AZ31 magnesium alloy extruded bar into a rectangular block sample and place it on the lower flat anvil of the hydraulic press, first take the X axis as the compression axis, and -4 the s -1 compression deformation at a strain rate of . When the true strain in the X direction reaches 0.2, the compression is stopped, and the sample is rotated 90 degrees, with the Y axis as the compression axis, and compressed again. When the true strain in the Y direction reaches 0.2, the compression is stopped, and the sample is rotated 90 degrees, with the Z axis as the compression axis, and compressed again. When the true strain in the Z direction reaches 0.2, the compression is stopped, the sample is rotated 90 degrees, and then the X axis is used as the compression axis, and the compression in the X→Y→Z→X direction is repeated. When the true strain in each direction is accumulated to 2, the twin-strengthened bulk nano-magnesium alloy with an average size of less than 0.5 μm...

Embodiment 2

[0039] Cut the AZ31 magnesium alloy extruded bar into a rectangular block sample and place it on the lower flat anvil of the hydraulic press, first take the X axis as the compression axis, and -2 the s -1 compression deformation at a strain rate of . When the true strain in the X direction reaches 0.1, the compression is stopped, and the sample is rotated 90 degrees, with the Y axis as the compression axis, and compressed again. When the true strain in the Y direction reaches 0.1, the compression is stopped, and the sample is rotated 90 degrees, with the Z axis as the compression axis, and compressed again. When the true strain in the Z direction reaches 0.1, the compression is stopped, the sample is rotated 90 degrees, and then the X axis is used as the compression axis, and the compression in the X→Y→Z→X direction is repeated. When the cumulative true strain in each direction reaches 1.5, the twin-strengthened bulk nano-magnesium alloy with an average size of less than 0.3...

Embodiment 3

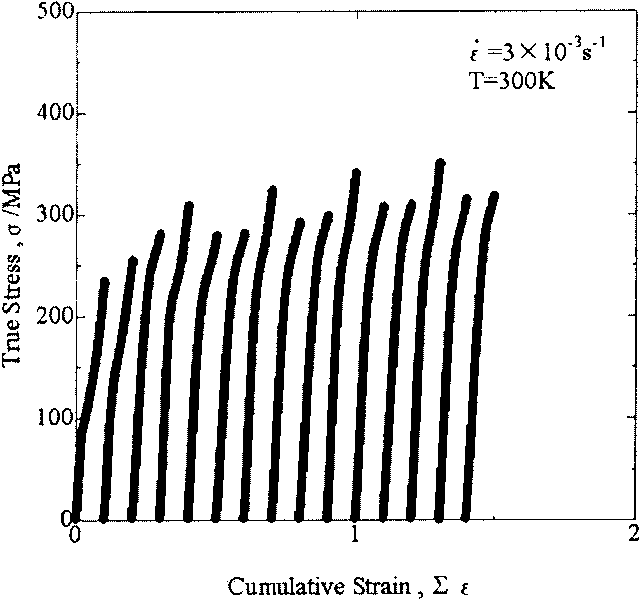

[0041] Cut AZ31 magnesium alloy extruded rods into rectangular block samples, place them in liquid nitrogen at -196°C for 5 minutes, take them out and place them on the lower flat anvil of a hydraulic press, first take the X axis as the compression axis, 1 the s -1compression deformation at a strain rate of . When the true strain in the X direction reaches 0.05, stop the compression, put the sample back into the liquid nitrogen for 5 minutes and take it out, rotate the sample 90 degrees, take the Y axis as the compression axis, and compress again. When the true strain in the Y direction reaches 0.05, the compression is stopped, and the sample is placed in liquid nitrogen for 5 minutes and then taken out, and the sample is rotated 90 degrees, with the Z axis as the compression axis, and compressed again. When the true strain in the Z direction reaches 0.05, stop the compression, put the sample in liquid nitrogen for 5 minutes and take it out, rotate the sample 90 degrees, take...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com