Silicone oil fan clutch

A clutch and silicone oil technology, applied in the direction of machine/engine, engine components, engine cooling, etc., can solve the problems of limited working temperature range, low control accuracy, slow response speed, etc., to achieve a simple and practical overall structure, high control accuracy, Responsive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

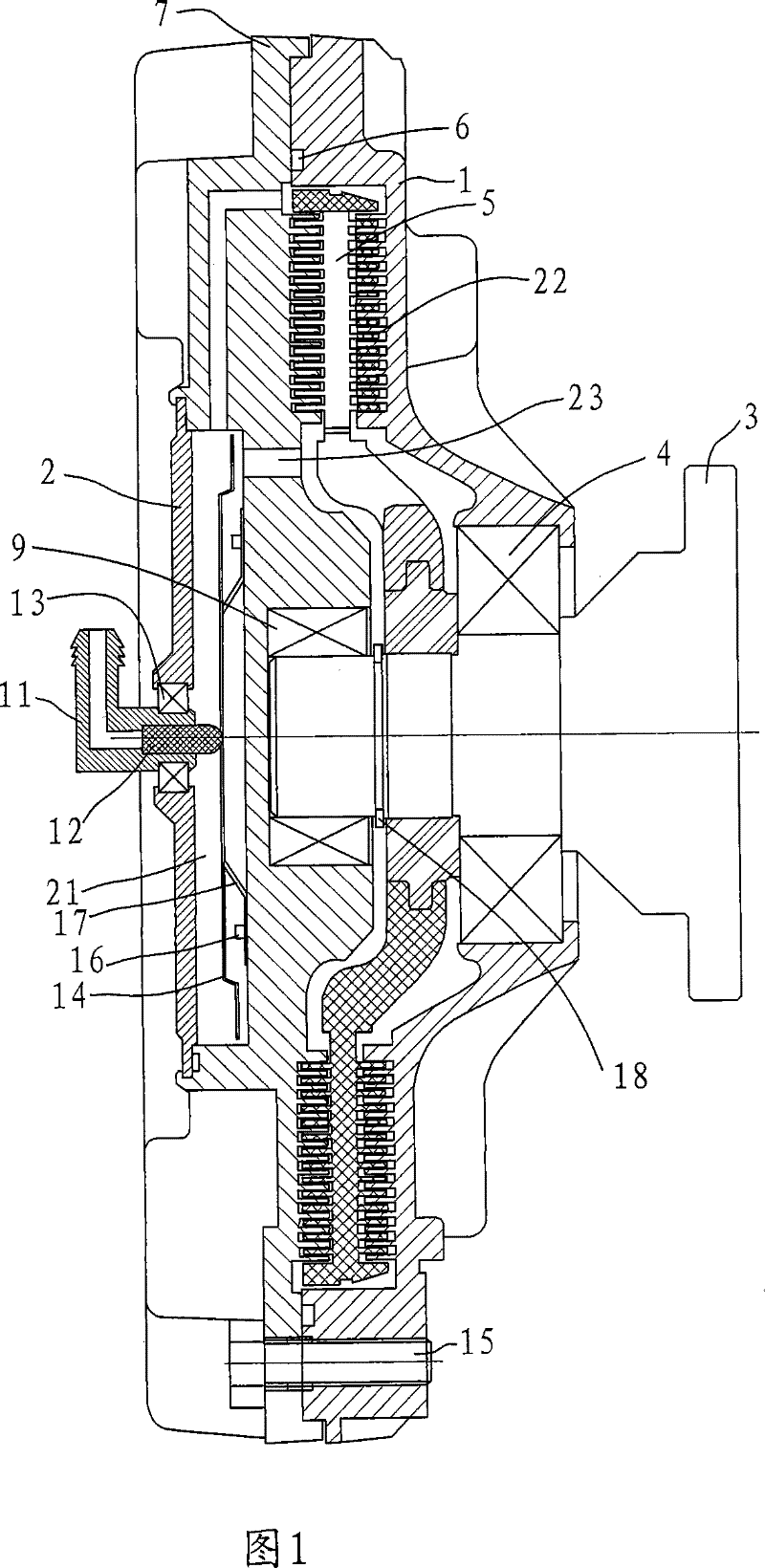

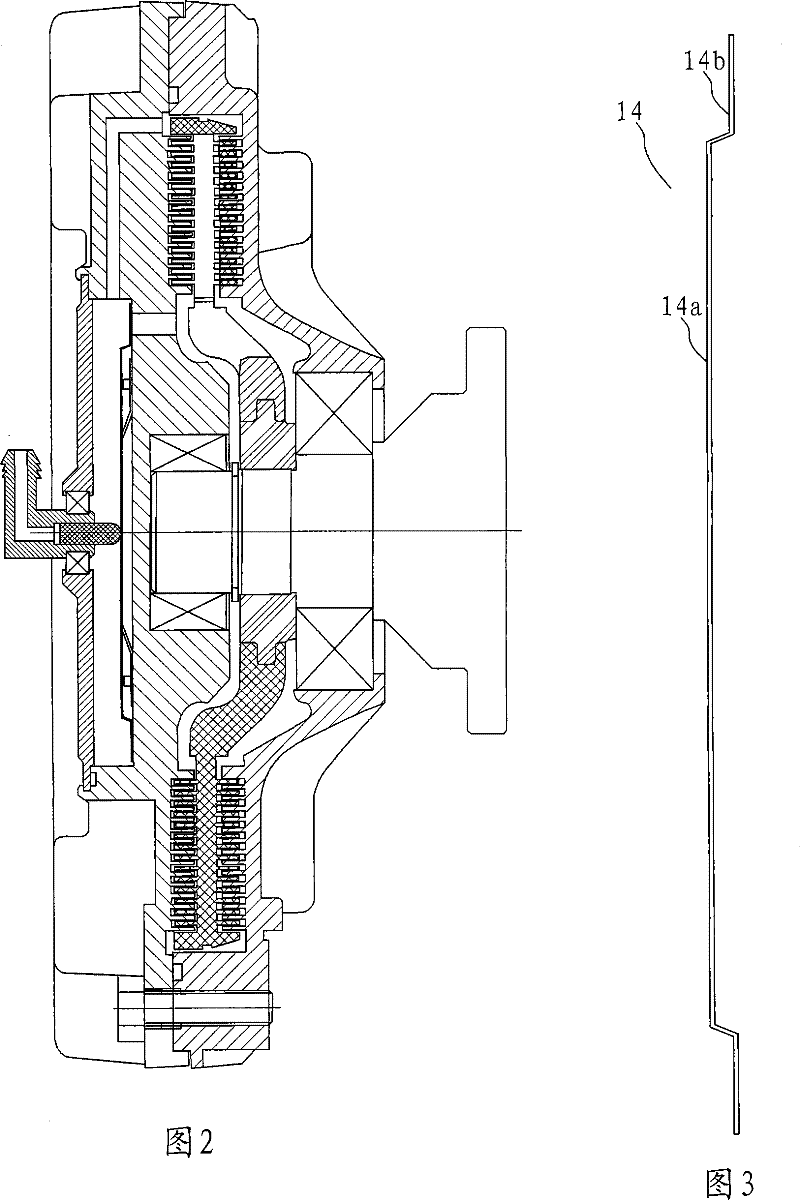

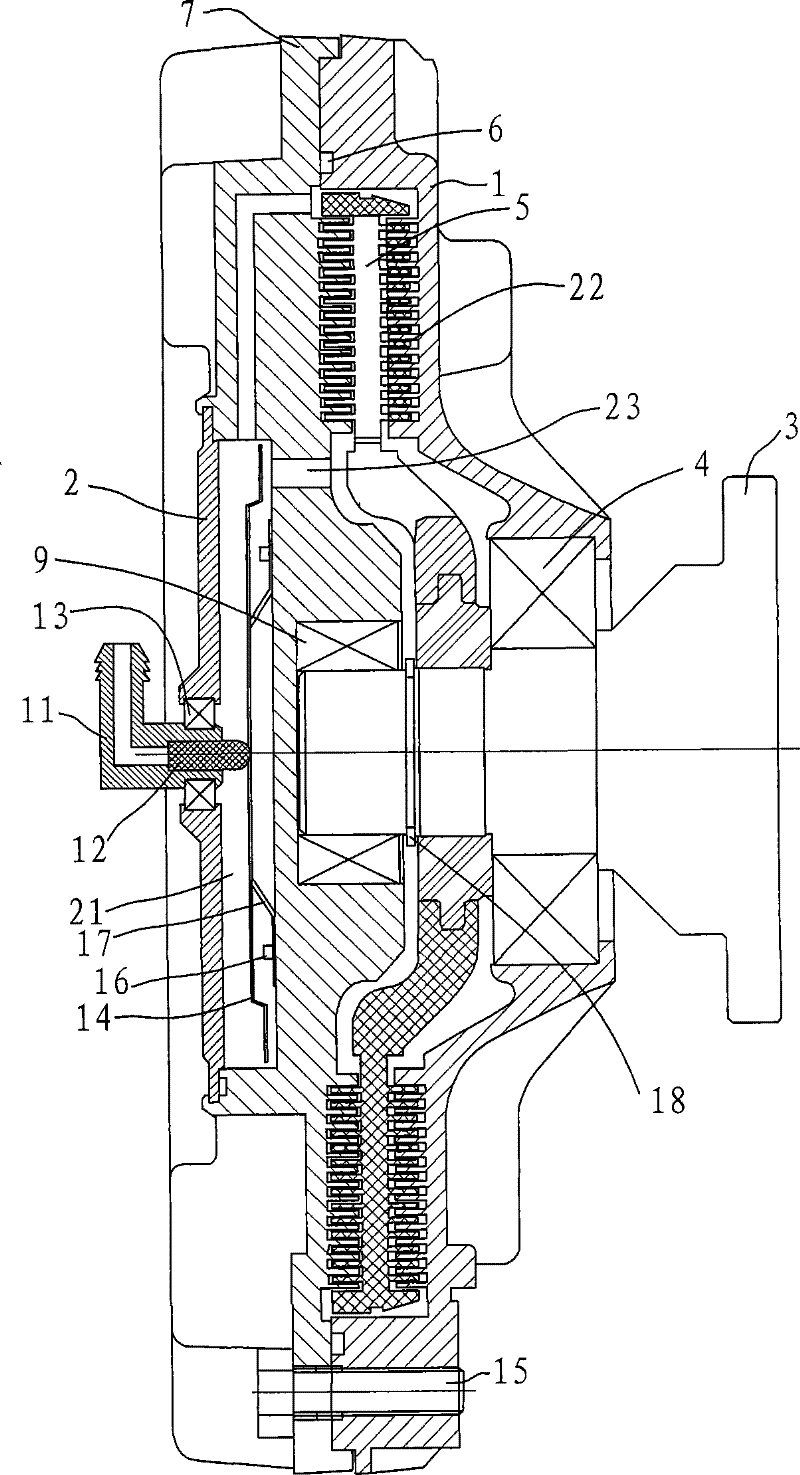

[0018] Example: such as figure 1 As shown, the silicon oil fan clutch in the present embodiment includes a housing 1, an oil storage cover 2, a valve plate 14, a front cover 7, a driving shaft 3 and a driving plate 5 arranged on the driving shaft 3, and the driving plate 3 passes through a card. The ring 18 is fixed on the drive shaft 3 and can rotate together with the drive shaft 3 . The front cover 7 is arranged on the driving shaft 3 through the front cover bearing 9, the housing 1 is arranged on the driving shaft 3 through the housing bearing 4, the front cover 7 is sealed with the housing 1, and a sealing ring 6 is arranged between them. And fixed by screw 15.

[0019] The oil storage cover 2 is arranged at the front end of the front cover 7 and forms an oil storage chamber 21 with the front cover 7, and an engagement cavity 22 is formed between the front cover 7, the housing 1 and the active plate 5, and the front cover 7 is provided with a storage chamber. The oil cha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com