Interlayer tensile strength detecting instrument for asphalt pavement

A technology for tensile strength and asphalt pavement, which is applied in the field of tensile strength detection devices, can solve the problems of low test accuracy, low degree of automation, and inconvenient use of the data acquisition and analysis system, and achieve rich on-chip peripheral modules that are not easy to fall off and sliding, easy installation and removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

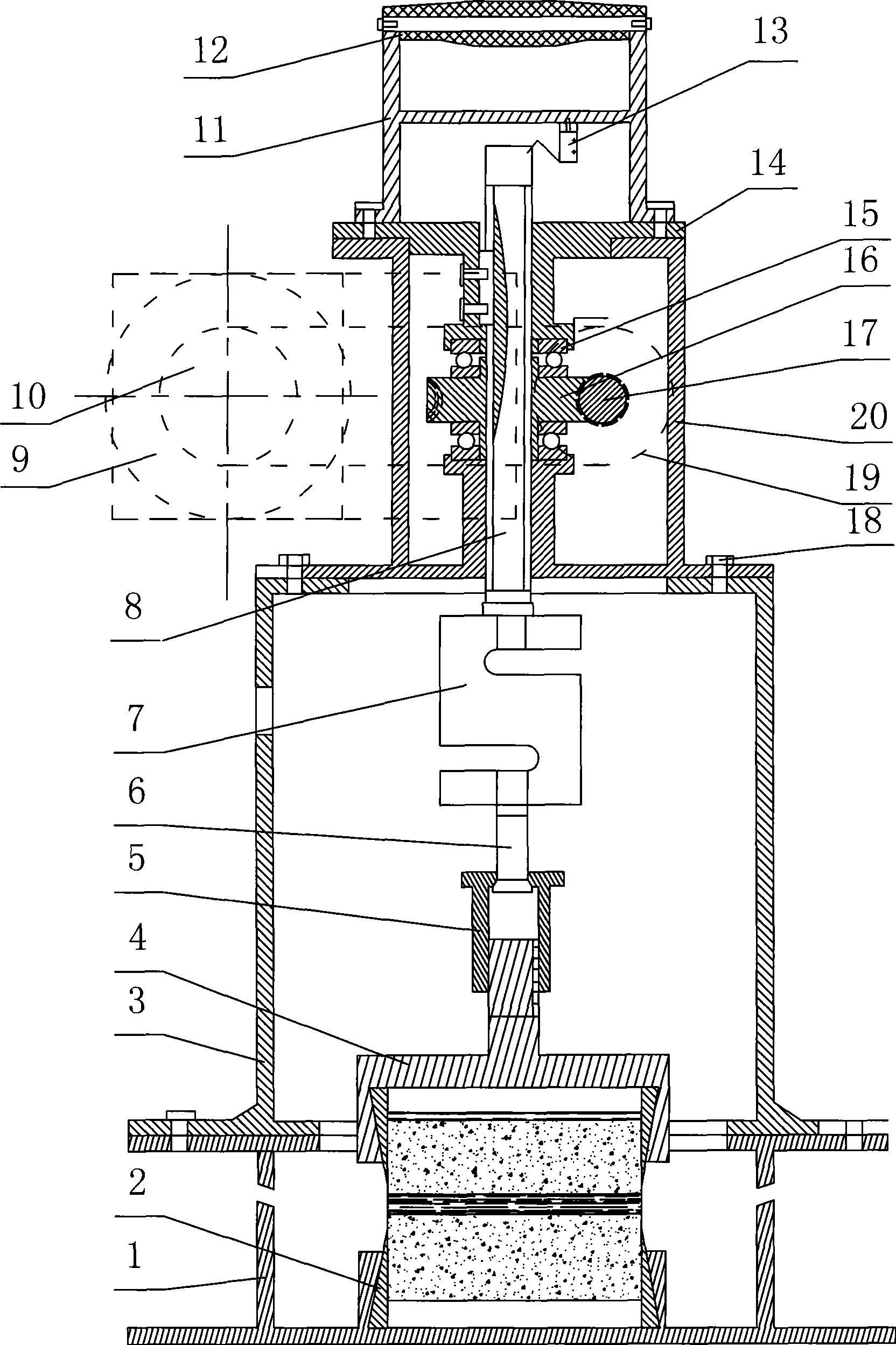

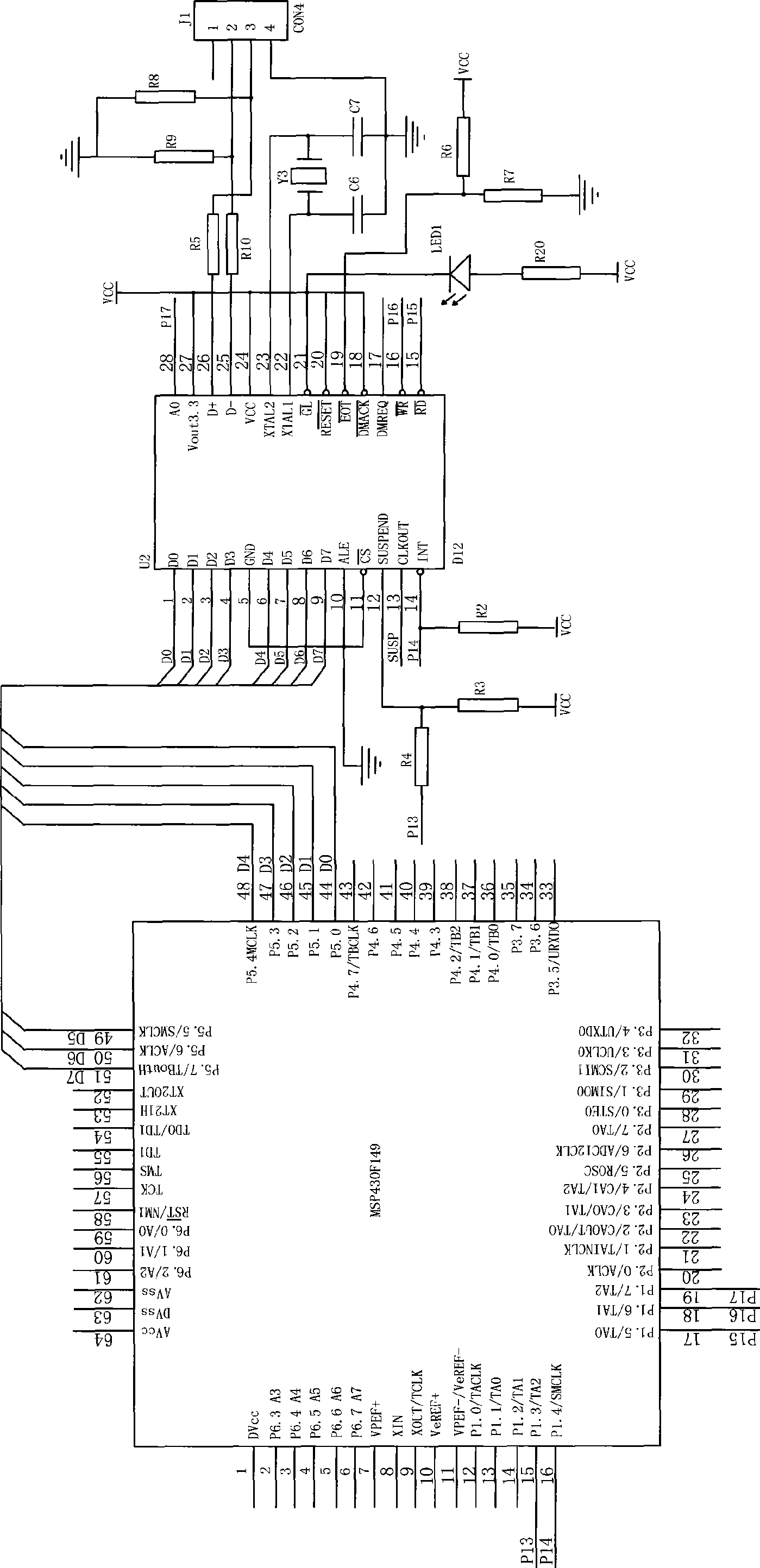

[0027] Such as figure 1 As shown, the present invention includes a frame, a driving motor, a clamping mechanism fixed on the inner bottom of the frame for clamping the detected part, located above the clamping mechanism and pulled up by the driving motor through the transmission part to be detected The pulling mechanism of the piece, the force sensor 7 for real-time detection of the pull-out force acting on the tested piece, and the displacement sensor for real-time detection of the displacement of the tested sample, and the detection signal of the force sensor 7 Analysis and processing and a data acquisition and control system that controls the drive motor accordingly according to the processing results, and a host computer connected to the data acquisition and control system; the force sensor 7 and the displacement sensor are both connected to the data acquisition and control system system, the drive motor is a stepper motor 9, and the data acquisition and control system is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com