Long-focus depth super-resolution secondary confocal measuring apparatus

A measurement device and super-resolution technology, which is applied in the field of high-resolution optical microscopic measurement, can solve the problems of restricting the application of confocal measurement technology to the change of surface reflectivity, large measurement errors, and low sensitivity of axial response signal measurement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

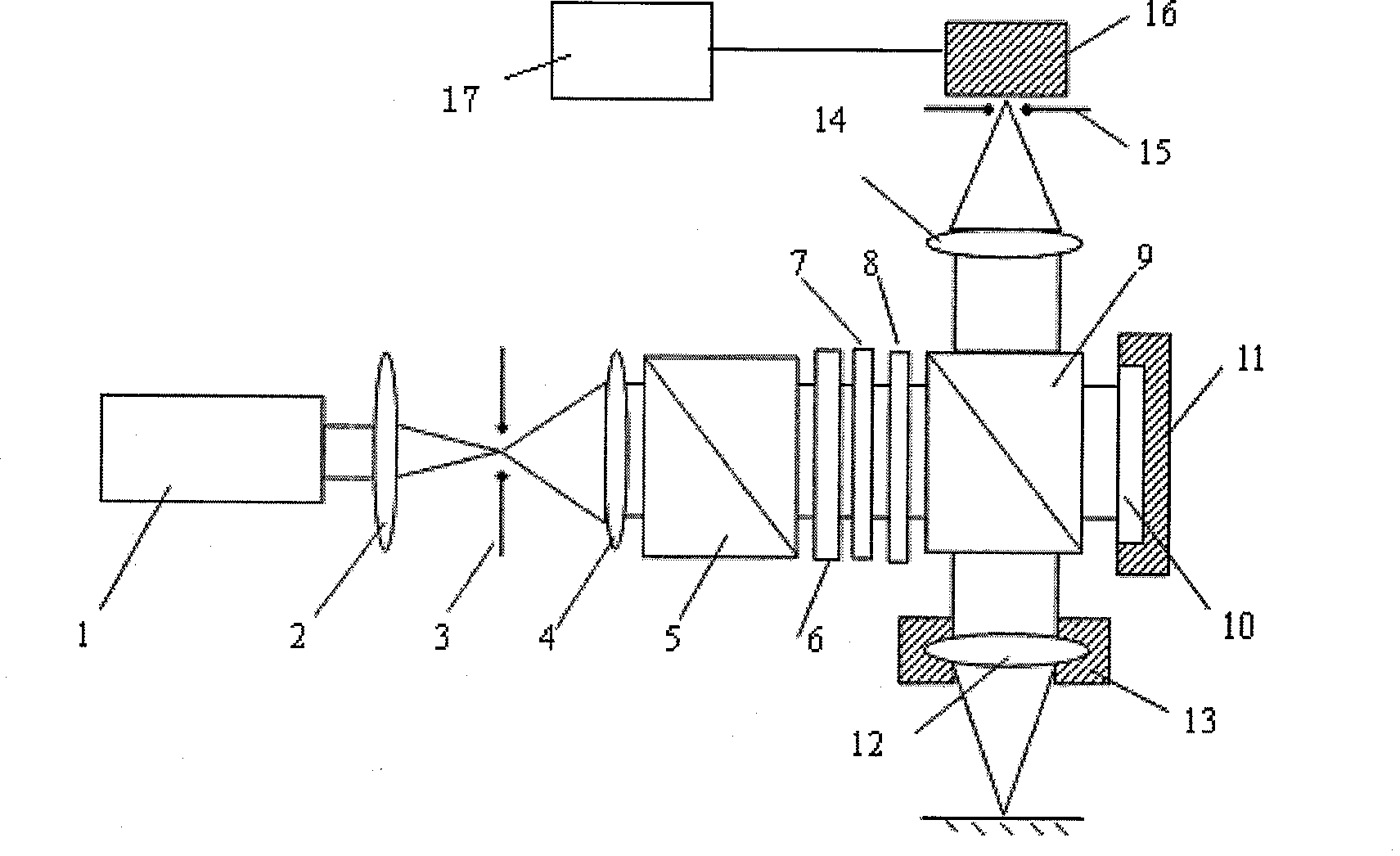

[0023] like figure 1 As shown, the secondary confocal measurement device for telephoto depth super-resolution provided by the present invention includes: laser 1; collimating and focusing objective lens 2; first pinhole 3; collimating beam expanding objective lens 4; polarizing beam splitter 5; A wave plate 6; a super-resolution filter 7; an adjustable aperture 8; a beam splitter 9; a mirror 10; Aperture 15; detector 16, and data processing means 17.

[0024] Wherein, the laser 1 emits a linearly polarized light beam, which becomes an approximately ideal plane wave after passing through the collimating beam expander lens group composed of the collimating focusing objective lens 2, the first pinhole 3, and the collimating beam expanding objective lens 4; After the quarter-wave plate 6, it becomes a circularly polarized light beam; after passing through the super-resolution filter 7, it becomes a modulated light beam carrying amplitude modulation information; the adjustable dia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com