Backlight module and production method of its substrate

The technology of a backlight module and a manufacturing method, which is applied in optics, nonlinear optics, instruments, etc., can solve the problems of increased thickness of liquid crystal display devices and blackheads of lamp tubes, and achieve simplification of the manufacturing process, convenience of the manufacturing process, and reduction of thickness Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In order to further understand the purpose, structure, features, and functions of the present invention, the detailed description of the accompanying examples is as follows.

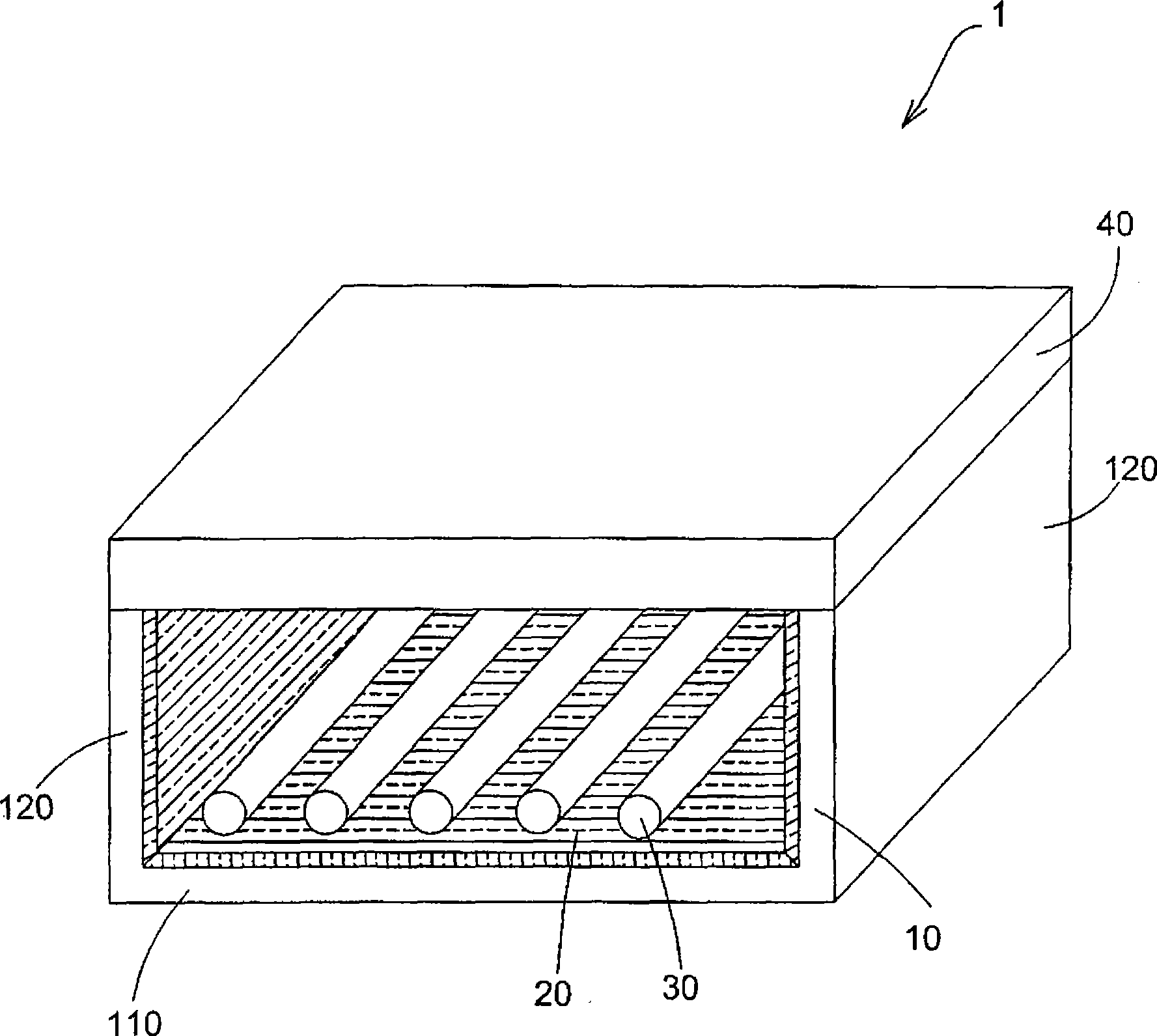

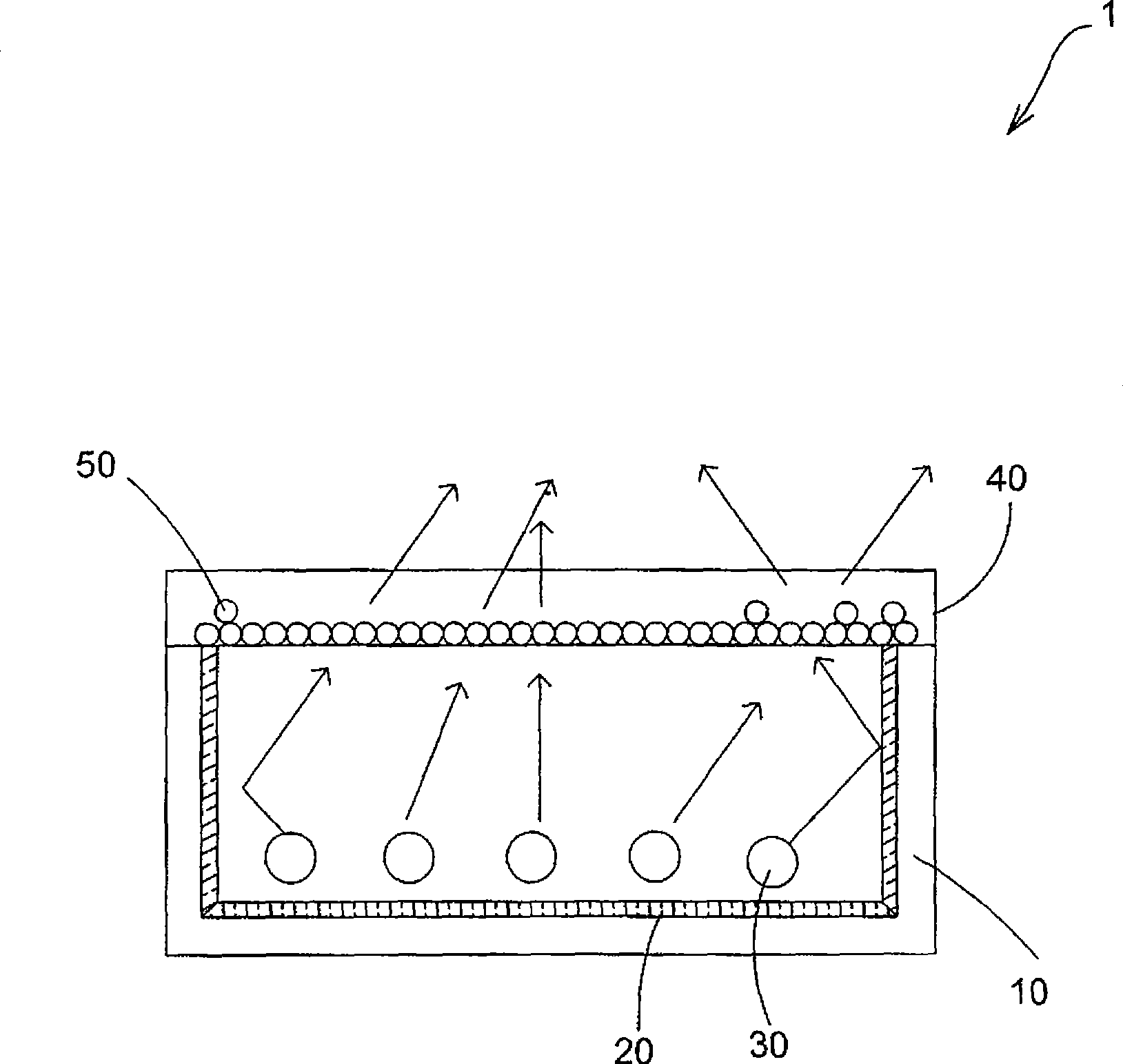

[0034] see figure 1 Shown is a three-dimensional structure diagram of the backlight module 1 of the present invention. As shown in the figure, the backlight module 1 of the present invention consists of a cavity-shaped reflector 10, a reflector 20 disposed on the inner wall of the cavity-shaped reflector 10, a plurality of lamp tubes 30 disposed inside the cavity-shaped reflector 10, and a cavity-shaped reflector. The reflector 10 is composed of a transparent substrate 40 .

[0035] The cavity-shaped reflector 10 is a reflector structure in which three flat plates are arranged in a concave shape. It has a base plate 110 and two side plates 120 perpendicular to the two ends of the base plate 110, for reflecting the light beam of the lamp tube 30 on the liquid crystal panel (not shown in the figure...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com