Preparing apparatus for granular active carbon

A technology of activated carbon and sand activated carbon, which is applied in the direction of products, carbon compounds, inorganic chemistry, etc., can solve the problems of technical difficulty in continuous production, high production cost, complicated production process, etc., and achieve effective separation, improve fluidization quality, reduce The effect of operating air velocity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

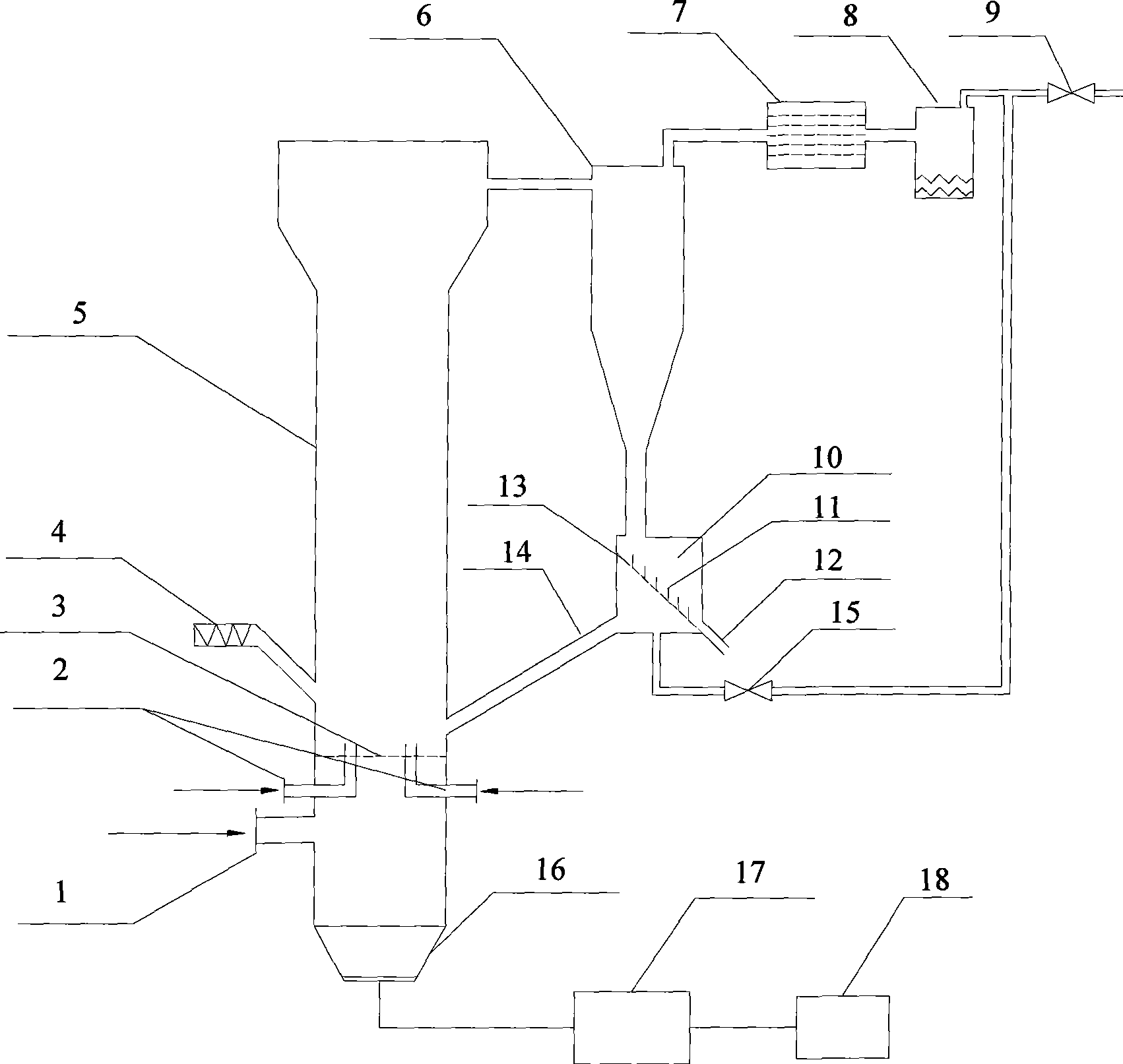

[0009] Embodiment: The main structure of this embodiment includes a nitrogen gas inlet 1, a double vertical jet tube type carbon dioxide gas inlet 2, a gas distribution plate 3, a biomass screw feed port 4, a circulating fluidized bed body 5, and a cyclone separator 6 , heat exchanger 7, gas-liquid separator 8, gas outlet control valve 9, activated carbon quartz sand separator 10, gas distribution plate baffle 11, activated carbon collection pipe 12, inclined gas distribution plate 13, quartz sand circulation feeding pipe 14. Gas inlet control valve 15, speaker 16, sound wave regulator 17 and sound wave generator 18; a nitrogen gas inlet 1 is arranged outside the lower end of the circulating fluidized bed main body 5 with a column structure, and the upper part of the nitrogen gas inlet 1 is symmetrical There are two double vertical jet tube carbon dioxide inlets 2, and a gas distribution plate 3 is arranged horizontally on the upper part of the carbon dioxide inlet 2, and at th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| aspect ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com