Preparation of inorganic magnetic material for filling hollow mesoporous silicon dioxide sphere

A silicon dioxide and magnetic material technology, applied in the direction of silicon dioxide, silicon oxide, etc., can solve problems such as time-consuming and cumbersome processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

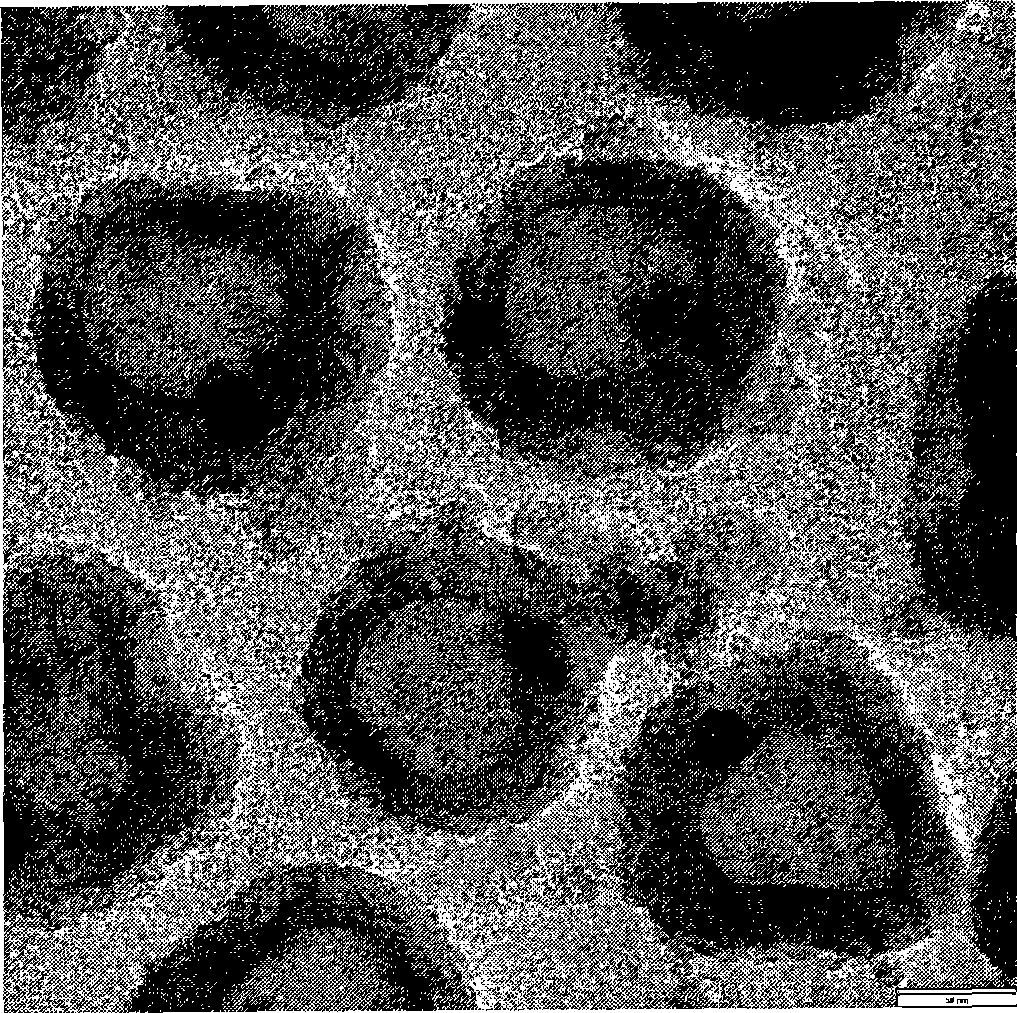

[0030] First prepare two kinds of reaction solutions: A solution is silicon source, alcohol and surfactant, the specific parameters are 30ml ethanol, 3ml tetraethyl orthosilicate, 1g CTAB; B solution is 0.05M ammonia solution. Second, the preparation of FeCl 2 with FeCl 3 For a solution with a molar ratio of 1:2, add 2ml of iron salt solution to 200ml of B solution to prepare a sol. Quickly add liquid A into the generated sol, reduce the stirring speed, and filter immediately after a light yellow precipitate appears after 3 minutes. After the filtrate was dried at room temperature, it was kept at 600° C. for one hour under the protection of nitrogen. Finally, the brown spherical wall is inlaid with magnetic Fe 3 o 4 hollow mesoporous silica spheres. Such as figure 1 , 5 , 6 shown.

Embodiment 2

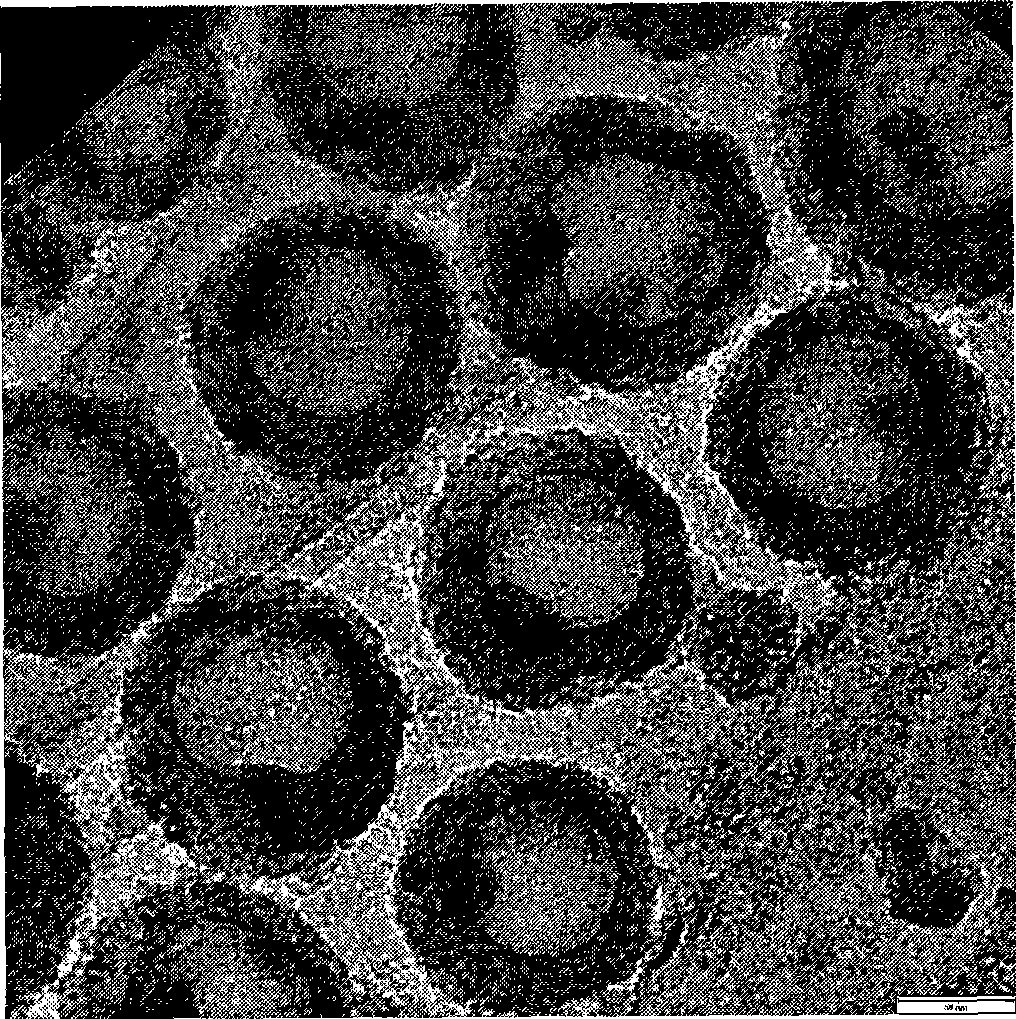

[0032] First prepare two kinds of reaction solutions: A solution is silicon source, alcohol and surfactant, the specific parameters are 30ml ethanol, 3ml tetraethyl orthosilicate, 1g surfactant; B solution is 0.05M ammonia solution. Second, the preparation of Fe(NO 3 ) 2 with Fe(NO 3 ) 3 For a solution with a molar ratio of 1:2, add 2ml of iron salt solution to 200ml of B solution to prepare a sol. Quickly add liquid A into the generated sol, reduce the stirring speed, and filter immediately after a light yellow precipitate appears after 3 minutes. After the filtrate was dried at room temperature, it was kept at 600° C. for one hour under the protection of nitrogen. Finally, the brown spherical wall is inlaid with magnetic Fe 3 o 4 hollow mesoporous silica spheres. Change the type of iron salt to make magnetic Fe embedded in the wall of the ball 3 o 4 The hollow mesoporous silica spheres have better morphology. Such as figure 2 shown.

Embodiment 3

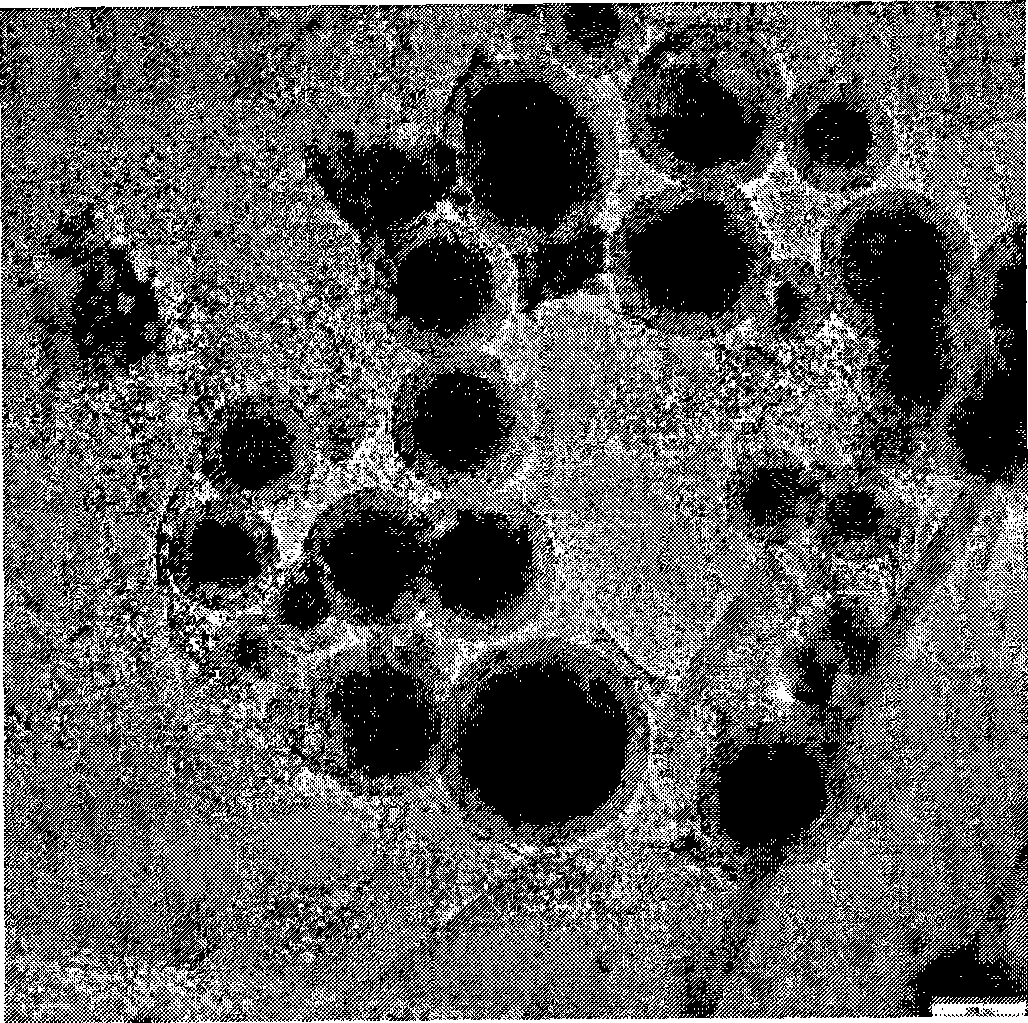

[0034] First prepare two kinds of reaction solutions: A solution is silicon source, alcohol and surfactant, the specific parameters are 30ml ethanol, 3ml tetraethyl orthosilicate, 1g CTAB; B solution is 0.05M ammonia solution. Second, the preparation of FeCl 2 with FeCl 3 For a solution with a molar ratio of 1:2, add 2ml of iron salt solution to solution A and stir for 20 minutes, then quickly add it to solution B, reduce the stirring speed, and filter immediately after a light yellow precipitate appears after 3 minutes. After the filtrate was dried at room temperature, it was kept at 600° C. for one hour under the protection of nitrogen. The resulting brown cavity is filled with magnetic Fe 3 o 4 mesoporous silica spheres. Such as image 3 , 6 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com