Biochemical treatment apparatus for wastewater treatment

A biochemical treatment device and an integrated technology, applied in water/sewage multi-stage treatment, biological water/sewage treatment, water/sludge/sewage treatment, etc., can solve high operating energy consumption, low processing load, and large footprint and other issues to achieve high-quality, high-processing-load effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

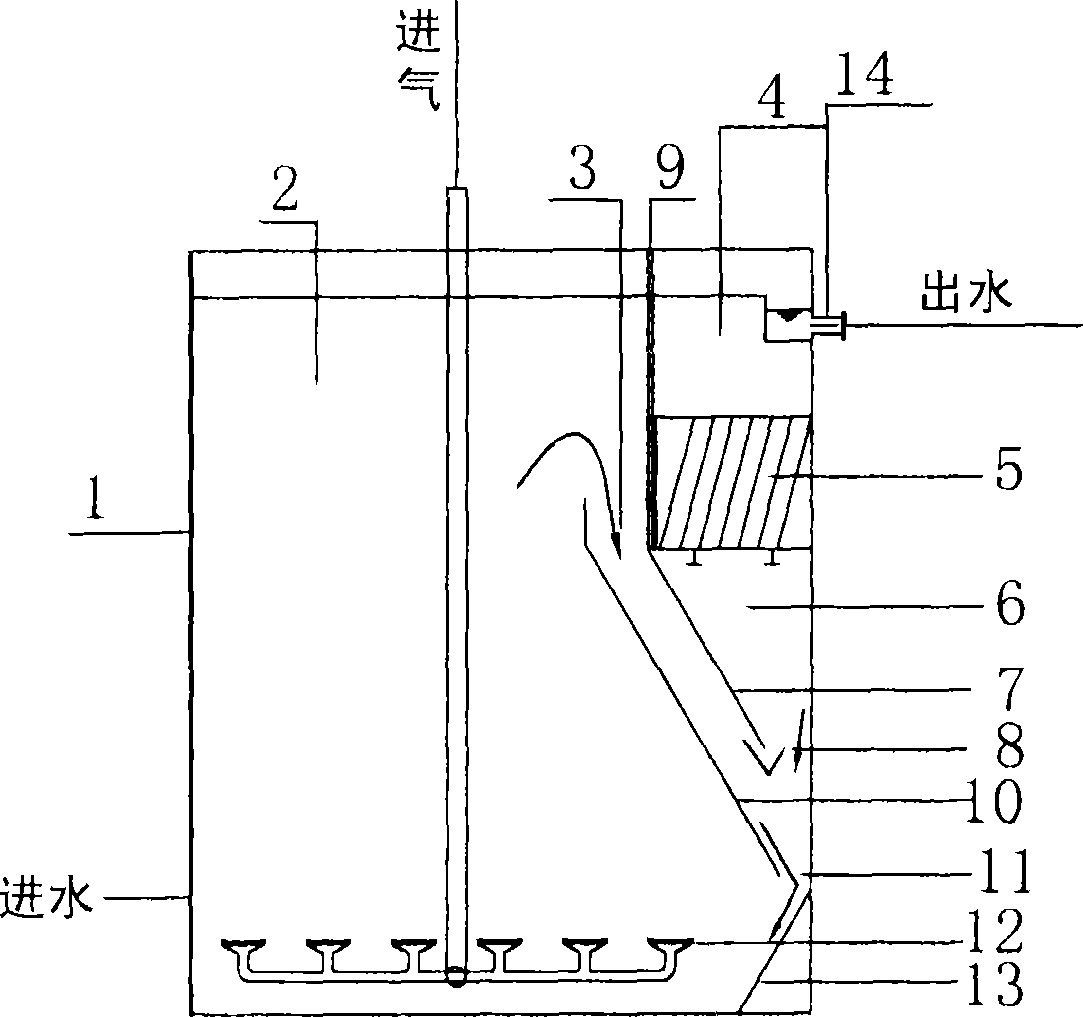

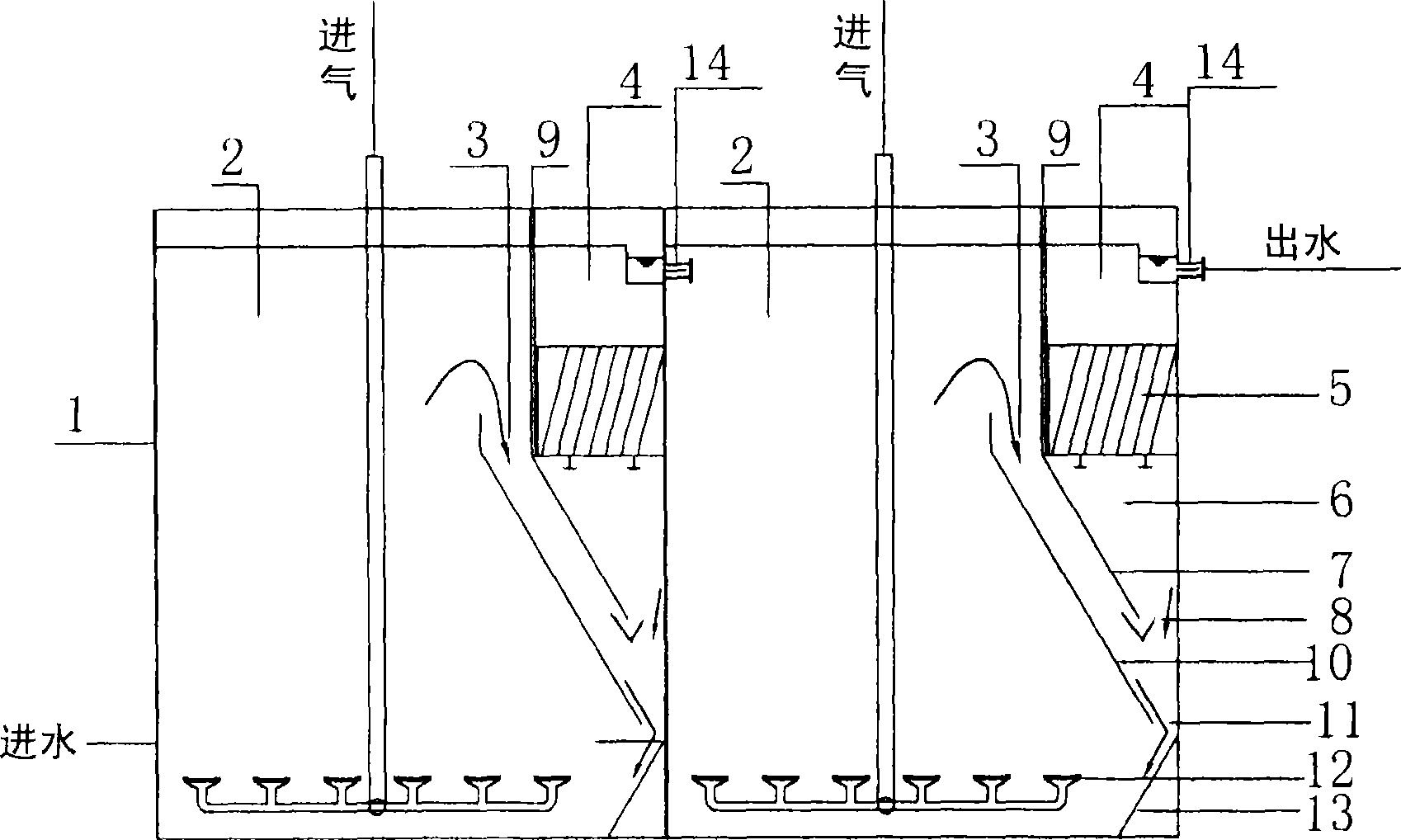

[0021] see figure 1 , is a schematic structural view of the biochemical treatment device of the present invention.

[0022] The biochemical treatment device 1 of the present invention is a container, which can be square or round, and can also be made of steel, glass fiber reinforced plastic or concrete. The biochemical treatment device 1 is filled with activated sludge, which may also be a flowable biological filler carrier.

[0023] The middle part of the biochemical treatment device is an aerobic aeration zone 2 ; one side inside the biochemical treatment device is provided with a reflux deflector 10 obliquely downward to form a mixed liquid reflux zone 3 . The return deflector 10 can be made of steel, PVC, ABS, glass fiber reinforced plastic or concrete. The upper end of the partition is lower than the water surface of the aerobic aeration area 2, and the lower end of the return deflector 10 is provided with a mixed liquid return slot 11 to communicate with the aerobic ae...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com