Toluene disproportionation process for producing high-purity benzene

A toluene disproportionation, high-purity technology, applied in the production of bulk chemicals, organic chemistry, hydrocarbons, etc., can solve the problems of low purity of benzene products, strict composition restrictions, and many side reactions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0014] Composition (by weight percentage) is to contain toluene 90%, non-aromatic 2%, benzene 1.0%, xylene 7%, the raw material of water content 400ppm all enters the rectification system to remove non-aromatic, benzene, xylene and other impurities, after purification The raw material composition (by weight percentage) is containing 99% of toluene, 0.5% of non-aromatic, 0.5% of xylene, and 150ppm of water. The purified raw material is mixed with circulating hydrogen, heated and then fed into the reactor, where it is contacted with a catalyst containing ZSM-5 molecular sieve for toluene disproportionation reaction. Reaction temperature 360°C, pressure 3.2MPa, hydrogen / aromatic molar ratio 2.8, space velocity 5.0h -1 , the weight concentrations of benzene, toluene and xylene in the obtained liquid product were 20.5%, 50.0% and 26.8% respectively, and the freezing point of the benzene product was 5.46°C. After 300 hours of reaction, the weight concentrations of benzene, toluene,...

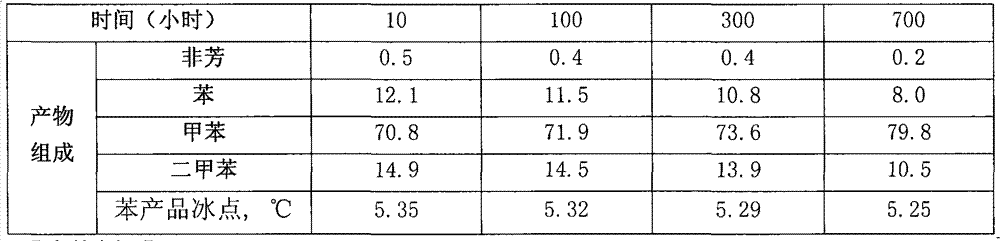

Embodiment 2

[0018] The composition (by weight percentage) is to contain 90.0% toluene, 2.0% non-aromatic, 8.0% xylene, and 450ppm water content. The raw material first enters the rectification system to remove impurities such as non-aromatic and xylene. %, non-aromatic 0.5%, xylene 0.5%, water 100ppm. The purified raw material and circulating hydrogen are heated and then enter the reactor, and contact with the catalyst containing ZSM-5 molecular sieve to carry out the toluene shape-selective disproportionation reaction. Reaction temperature 430°C, pressure 1.6MPa, hydrogen / aromatic molar ratio 2.0, space velocity 4.2h -1 , the weight concentrations of benzene, toluene and xylene in the obtained liquid product were 13.0%, 68.9% and 15.6% respectively, and the freezing point of the benzene product was 5.46°C.

Embodiment 3

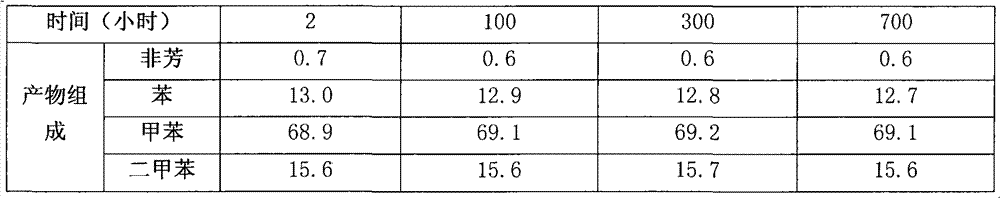

[0020] Composition (by weight percentage) is that the raw material containing toluene 97.0%, non-aromatic 0.9%, benzene 0.7%, xylene 1.4%, water 400ppm enters the rectification system, removes non-aromatic, benzene, xylene and other impurities, and the purified The raw material is composed of 98.5% toluene, 0.5% non-aromatic, 1.0% xylene and 150ppm water. The purified raw material and circulating hydrogen are heated and then enter the reactor, and contact with the catalyst containing ZSM-5 molecular sieve to carry out the toluene shape-selective disproportionation reaction. Reaction temperature 450°C, pressure 2.8MPa, hydrogen / aromatic molar ratio 2.8, space velocity 4.2h -1 , the liquid product composition (by weight percentage) that different reaction time obtains is shown in Table 1, and the freezing point of benzene product is 5.46 ℃.

[0021] Table 1 Toluene shape-selective disproportionation reaction change composition table with time

[0022]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com