Rotary hearth furnace and rotary hearth furnace waste gases utilization method

A rotary hearth furnace bottom and rotary hearth furnace technology, applied in the field of iron and steel smelting, to achieve the effects of efficient use of waste heat, fast heat transfer of furnace charge, and thick material layer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

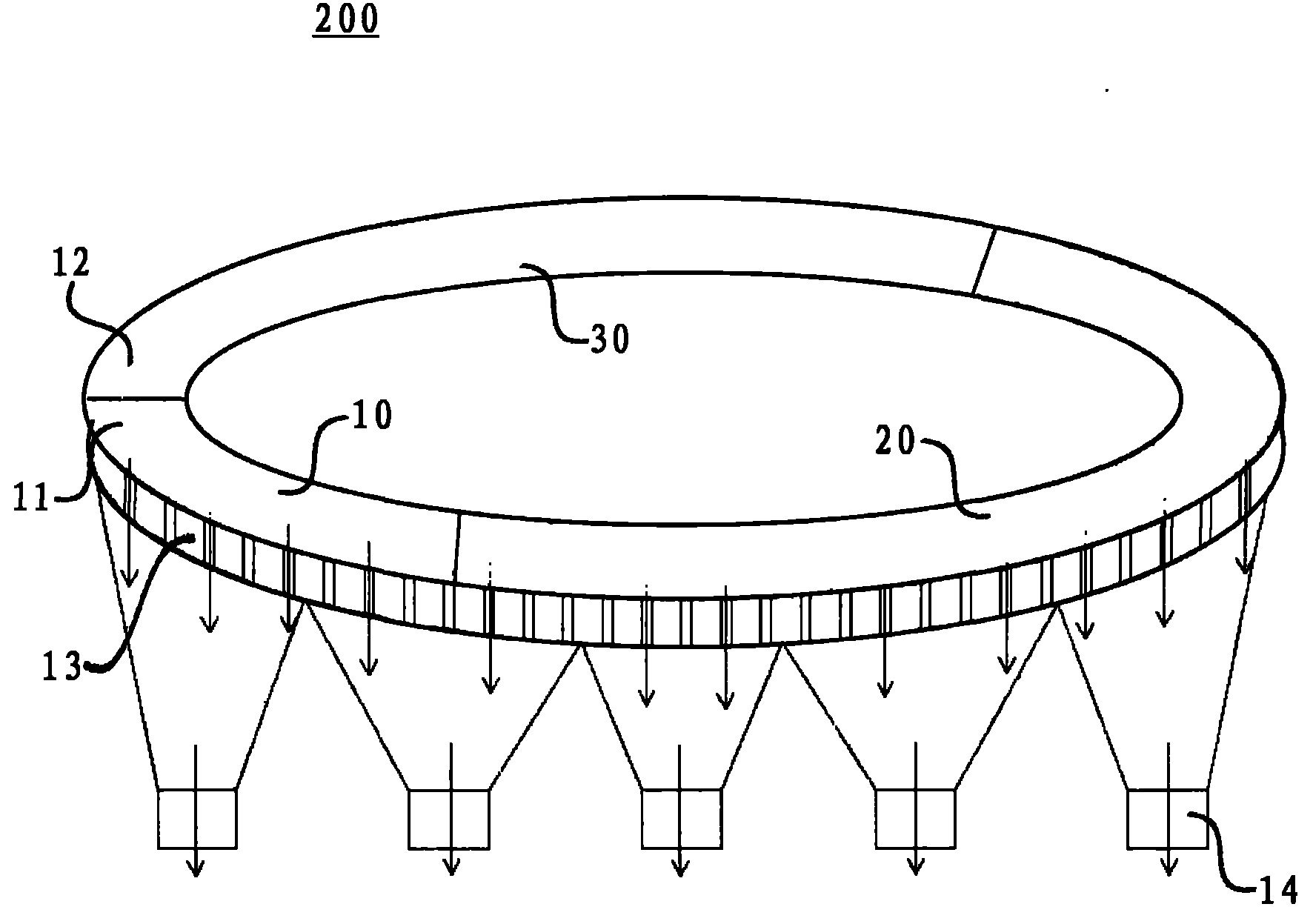

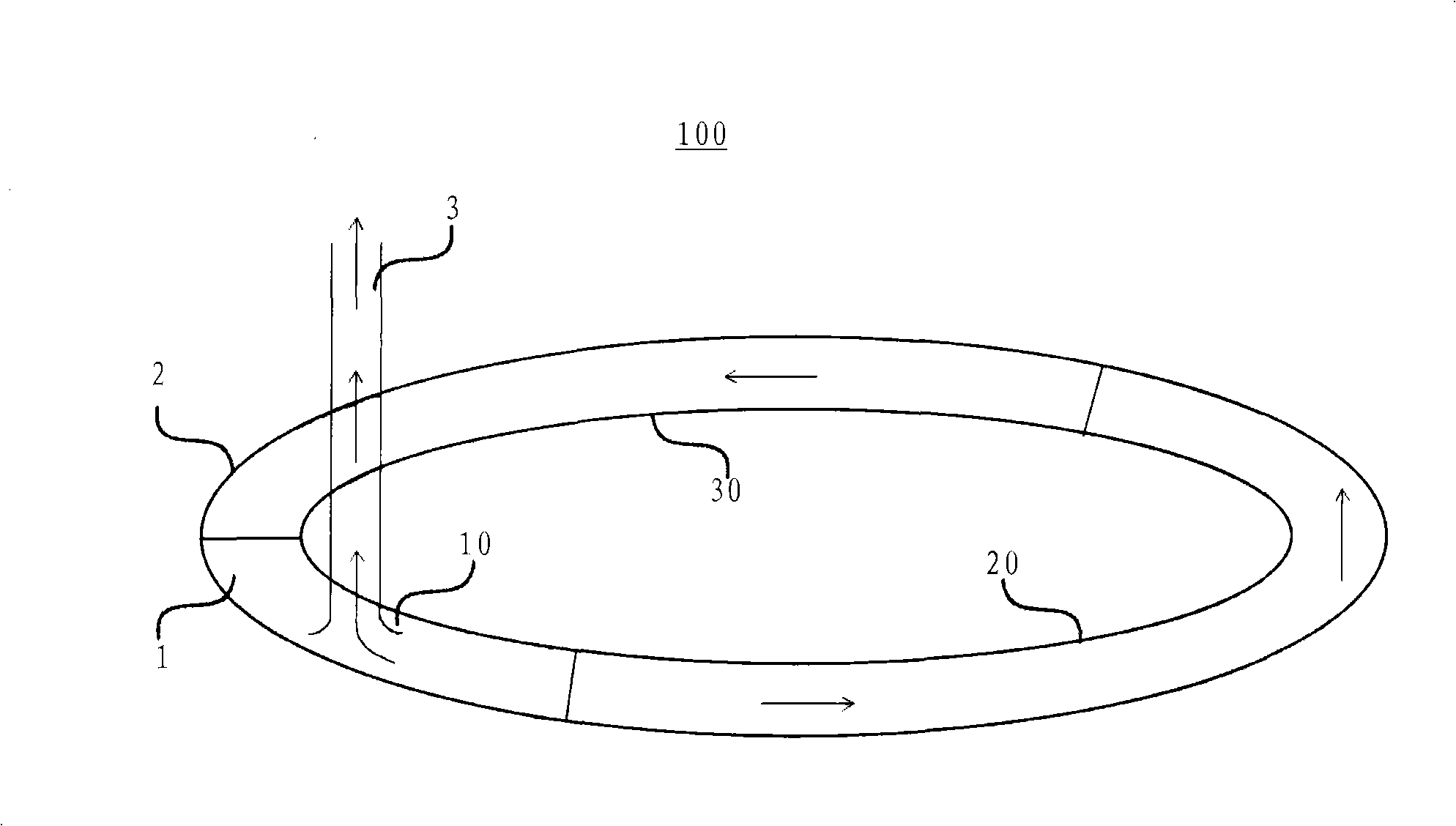

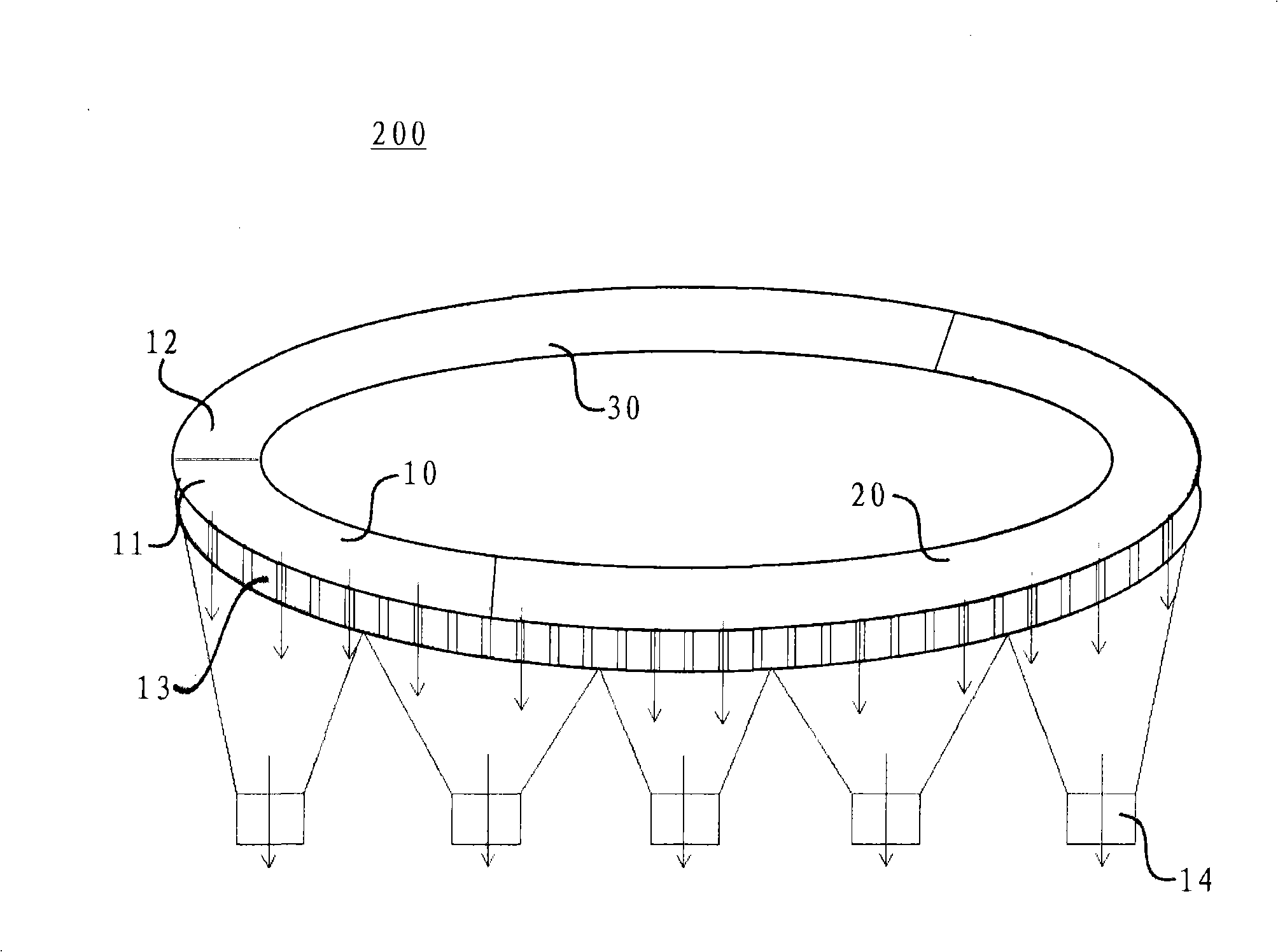

[0021] In the present invention, a waste gas utilization device is arranged on the furnace bottom of the rotary hearth furnace, and the waste gas utilization device is a ventilation brick 13 and an exhaust fan 14 arranged at the furnace bottom positions of the preheating section 10 and the reduction section 20 of the rotary hearth furnace 200; The furnace bottoms of the preheating section 10 and the reducing section 20 are laid with air-permeable bricks 13 , and a plurality of exhaust fans 14 are connected below the air-permeable bricks 13 .

[0022] Adopt the waste gas utilization method of the rotary hearth furnace of the present invention, at first send the carbon-containing pellet charge into the rotary hearth furnace of the present invention, directly make the material layer thickness reach 100mm, when the rotary hearth furnace is heated, use the exhaust fan 14 to The high-temperature waste gas generated in the heating section and the reduction section is extracted through...

Embodiment 2

[0024] On the basis of the improved rotary hearth furnace structure of embodiment 1, adopt the rotary hearth furnace exhaust gas utilization method of the present invention, at first send carbon-containing pellet charge in the rotary hearth furnace of the present invention, directly make material layer thickness reach 200mm, During the heating operation of the rotary hearth furnace, the exhaust fan 14 is used to extract the high-temperature exhaust gas generated in the preheating section and the reduction section through the ventilating brick 13, and the high-temperature exhaust gas is generated in the furnace charge in the preheating section and the reduction section for convective heat transfer; The exhaust gas extraction process is to perform forced preheating, heat transfer and heating on the carbon-containing pellets in the preheating section and reduction section of the rotary hearth furnace, and promote the reduction of the carbon-containing pellets. The metallization ra...

Embodiment 3

[0026]On the basis of the improved rotary hearth furnace structure of embodiment 1, adopt the rotary hearth furnace exhaust gas utilization method of the present invention, at first send carbon-containing pellet charge in the rotary hearth furnace of the present invention, directly make material layer thickness reach 300mm, During the heating operation of the rotary hearth furnace, the exhaust fan 14 is used to extract the high-temperature exhaust gas generated in the preheating section and the reduction section through the ventilating brick 13, and the high-temperature exhaust gas is generated in the furnace charge in the preheating section and the reduction section for convective heat transfer; The exhaust gas extraction process is to perform forced preheating, heat transfer and heating on the carbon-containing pellets in the preheating section and reduction section of the rotary hearth furnace, and promote the reduction of the carbon-containing pellets. The metallization rat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com