Miniature propeller based on MEMS nozzle chip

A micro-propulsion and chip technology, which is applied in jet propulsion devices, machines/engines, rocket engine devices, etc., can solve the problems of small catalytic area, lower reliability of propellers, serious heat loss of tiny silicon chips, etc., and achieve power consumption Small, light weight, small size effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

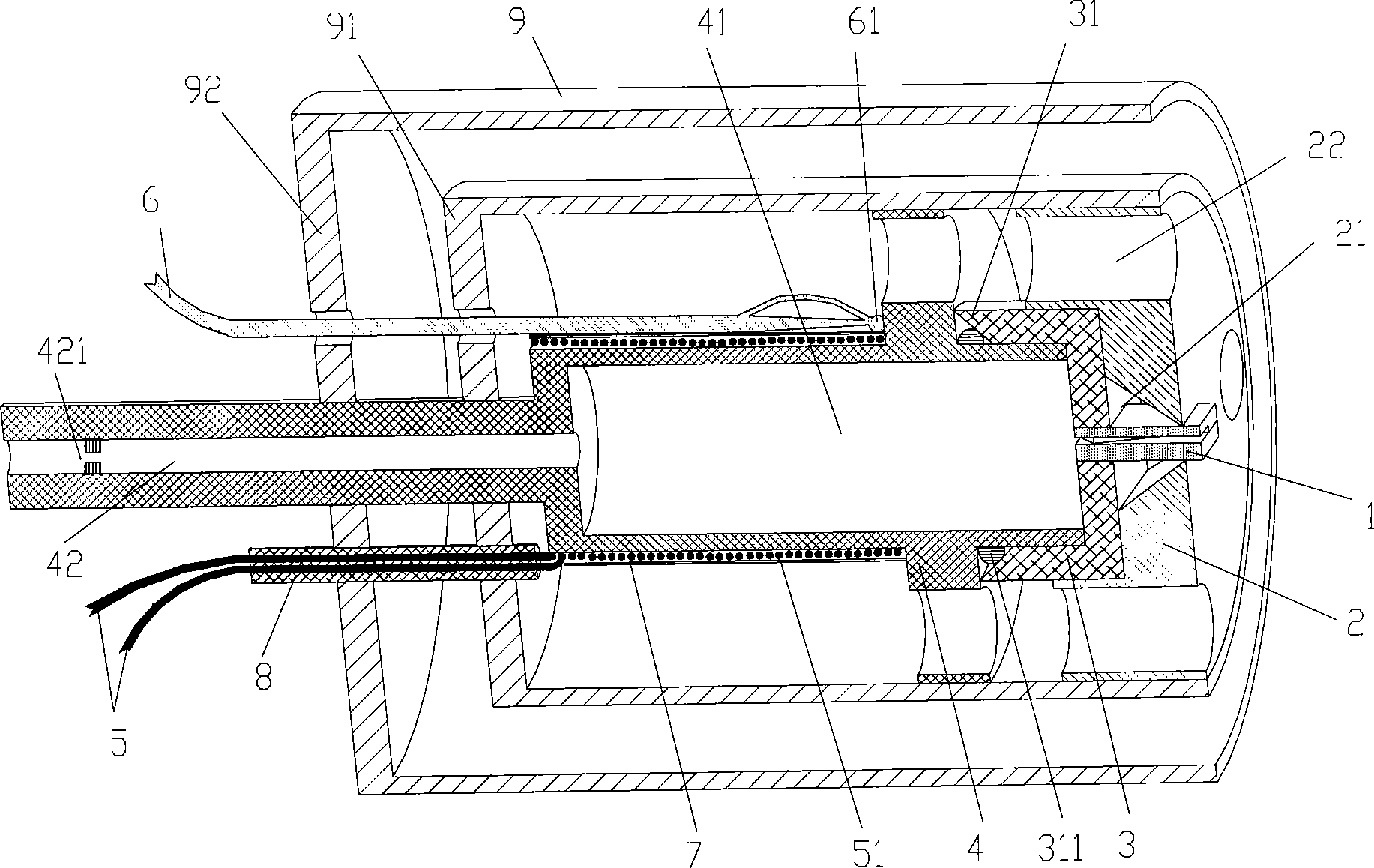

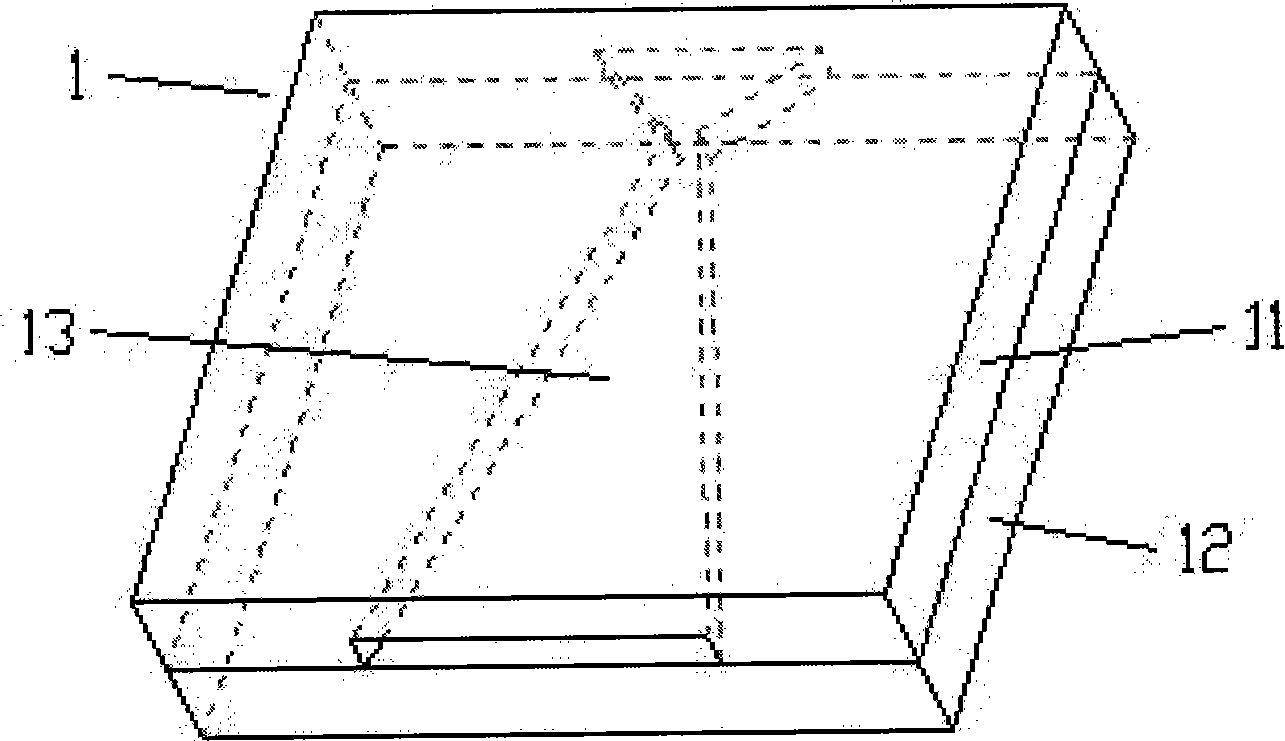

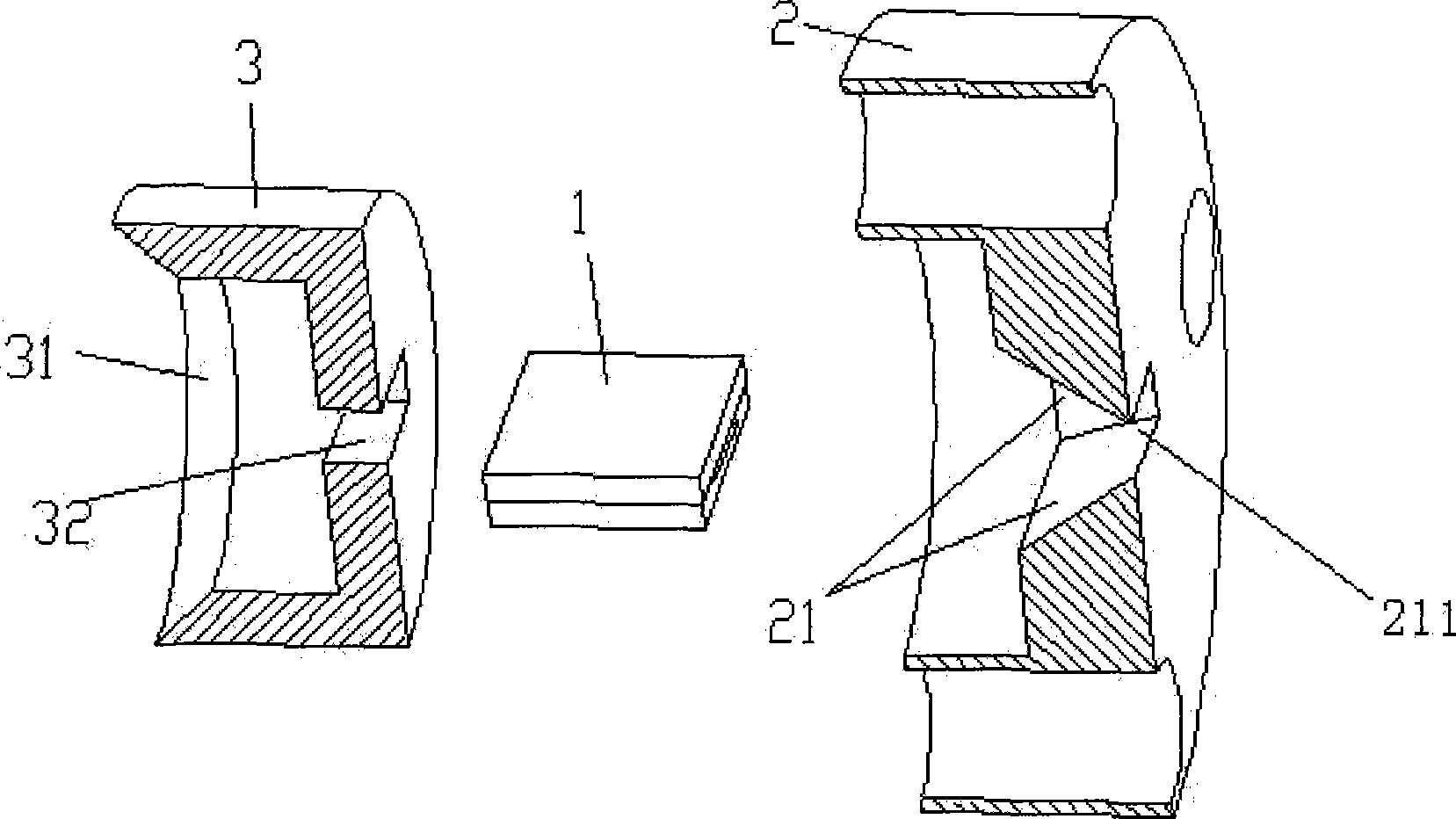

[0023] see figure 1 Shown, a kind of micro-propeller based on MEMS nozzle chip comprises radiation heat-insulating shell 9, catalytic reaction chamber 4, top cover 2, and catalytic reaction chamber 4 comprises the catalytic cavity 41 that is arranged in the radiation heat-insulating shell 9, catalysis The inlet channel 42 of the reaction chamber, one end of the inlet channel 42 of the catalytic reaction chamber is connected to the catalytic chamber 41, and the other end passes through the radiation heat insulation shell 9; the sealing sleeve is provided with the middle sleeve 3 on the front end of the catalytic chamber 41, and the sealing sleeve of the top cover 2 Located on the periphery of the middle set 3, a MEMS nozzle chip 1 is pierced in the middle of the middle set 3. One end of the MEMS nozzle chip 1 is connected to the catalytic chamber 41, and the other end passes through the top cover 2. Heated heating wire 5.

[0024] After the liquid propellant such as high-conce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com