Off-course driving device of non-off course gear used for aerogenerator

A technology of yaw driving device and wind generator, which is applied in the control of wind turbines, wind turbines, wind power generation, etc. It can solve the problems of reduced power generation efficiency, low yaw accuracy, and many actuators, and achieve the improvement of yaw accuracy. , Improve system reliability and reduce noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

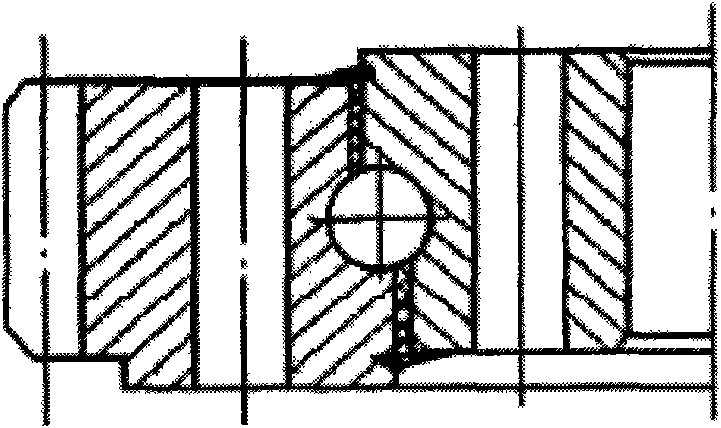

[0009] Specific implementation mode one: as Figure 4~5 As shown, the yaw driving device without yaw gear on the wind power generator described in this embodiment includes a yaw main shaft 40, and the yaw driving device also includes a closed oil tank 20, a frequency conversion motor 21, a shaft coupling device 22, two-way quantitative pump 23, oil supply valve assembly 24, two-way hydraulic lock 25, low-speed high-torque hydraulic motor 26 and manual cut-off valve 27, frequency conversion motor 21 is connected with two-way quantitative pump 23 through coupling 22, and two-way quantitative pump 23 and the low-speed high-torque hydraulic motor 26 form a closed circuit 30, the oil supply valve assembly 24 is connected in parallel on the closed circuit 30 and communicates with the closed oil tank 20, and the two-way hydraulic lock 25 is connected in series on the closed circuit 30, The manual cut-off valve 27 communicates with the high and low pressure cavity of the low-speed hig...

specific Embodiment approach 2

[0010] Specific implementation mode two: as Figure 5 As shown, the yaw driving device in this embodiment also includes a yaw damper, and the yaw damper is composed of a hydraulic clutch 34, a pump 32, a motor 33, a proportional overflow valve 31 and an oil tank 35, and the hydraulic clutch 34 is installed On the shaft of the low-speed high-torque hydraulic motor 26, the inlet end of the pump 32 communicates with the oil tank 35, the hydraulic clutch 34 is connected with the outlet end of the pump 32, the pump 32 is connected with the motor 33, and the proportional relief valve 31 is arranged between the pump 32 and the hydraulic pressure. On the oil road between the clutches 34. In order to meet the power-off safety standards, a hydraulic clutch is installed on the low-speed high-torque hydraulic motor shaft as an emergency braking device. When the hydraulic system loses pressure, the hydraulic clutch acts to hold the hydraulic motor shaft tightly to achieve power-off safety....

specific Embodiment approach 3

[0011] Specific implementation mode three: as Figure 5 As shown, the replenishment valve assembly 24 in this embodiment is composed of two plug-in hydraulic control check valves 24-1. Other compositions and connections are the same as those in Embodiment 1 or 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com