Method for implementing fast measurement of inductive winding DC resistance by using constant voltage source

A technology of DC resistance and constant voltage source, which is applied in the direction of measuring devices, measuring electrical variables, measuring resistance/reactance/impedance, etc., can solve problems such as time-consuming and laborious, long test time, large-capacity load inductance, etc., to overcome the operation The effect of long time, stable and intuitive reading, high accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

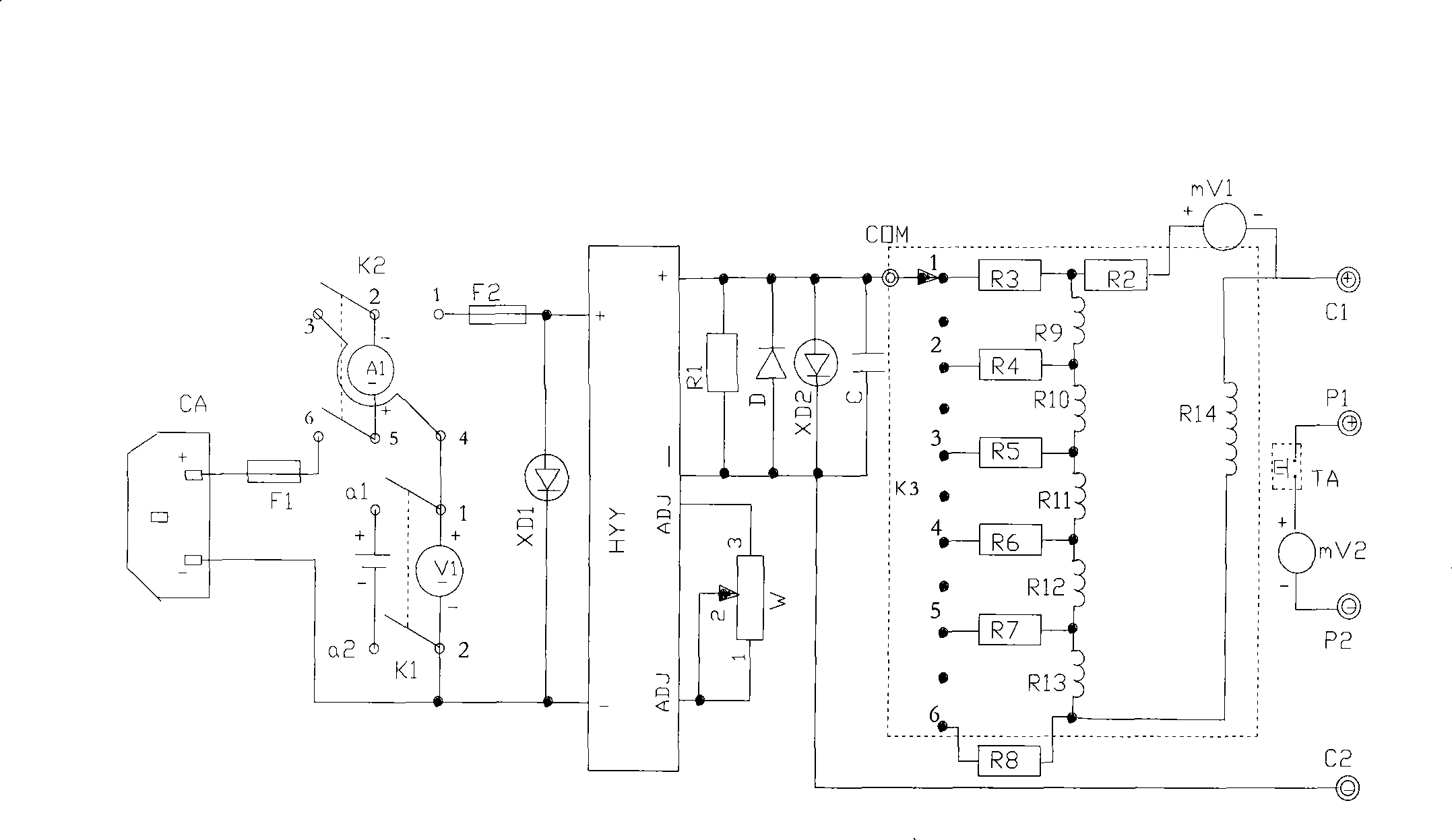

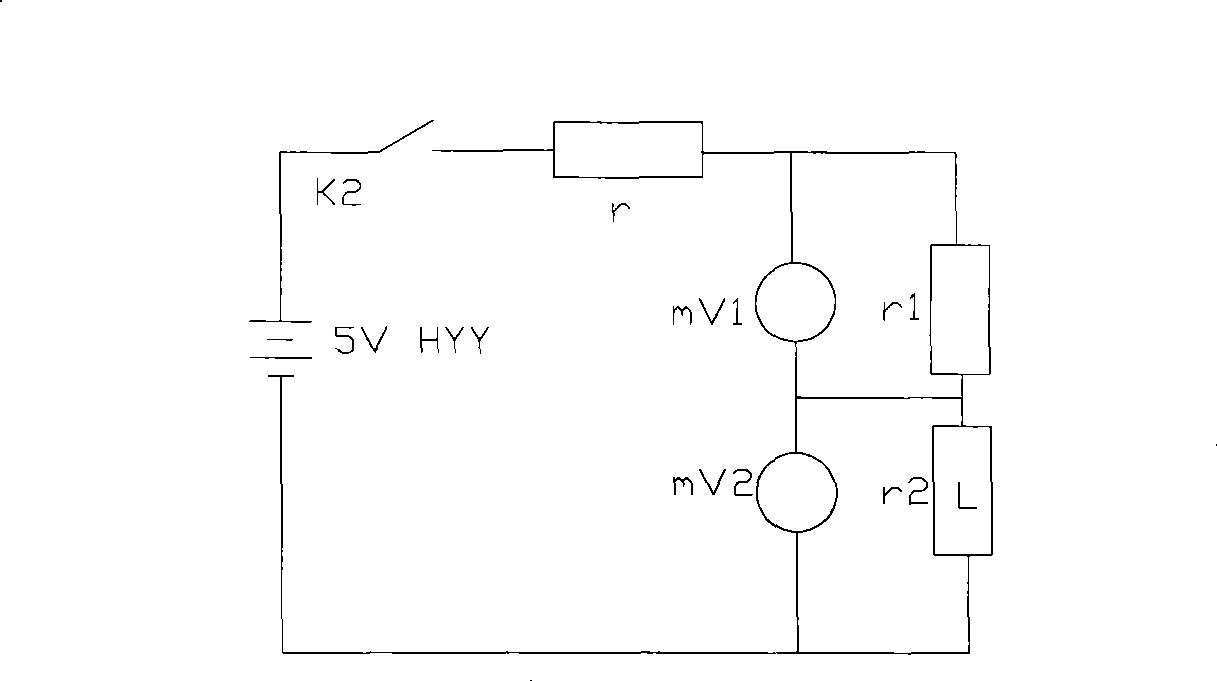

[0014] The method for realizing the rapid measurement of the direct current resistance of the inductive winding provided by the present invention is to use the constant voltage source in the fast measuring instrument for the direct current resistance of the inductive winding to maintain a constant working voltage, and select the range according to the resistance range of the winding of the inductive device to be tested, The measuring loop current is adjusted by changing the resistance value of the range circuit to realize fast measurement, and the speed measurement is less than 100 seconds; the circuit composition of the fast measuring instrument includes a control circuit of a power supply device, a range circuit, a millivolt meter and a constant voltage source. The model of the constant voltage source is 4NIC-DC75W.

[0015] The method for realizing the fast measurement of the DC resistance of an inductive winding by using a constant voltage source provided by the invention i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com