Mixed fault information extraction and matching technique for chemical production

A fault information, chemical production technology, applied in electrical testing/monitoring and other directions, can solve problems affecting process control fault diagnosis performance, information loss, affecting the accuracy and reliability of data processing, etc., to achieve practical application and strong operability , the effect of increasing capacity and improving performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention is described in detail below with reference to accompanying drawing:

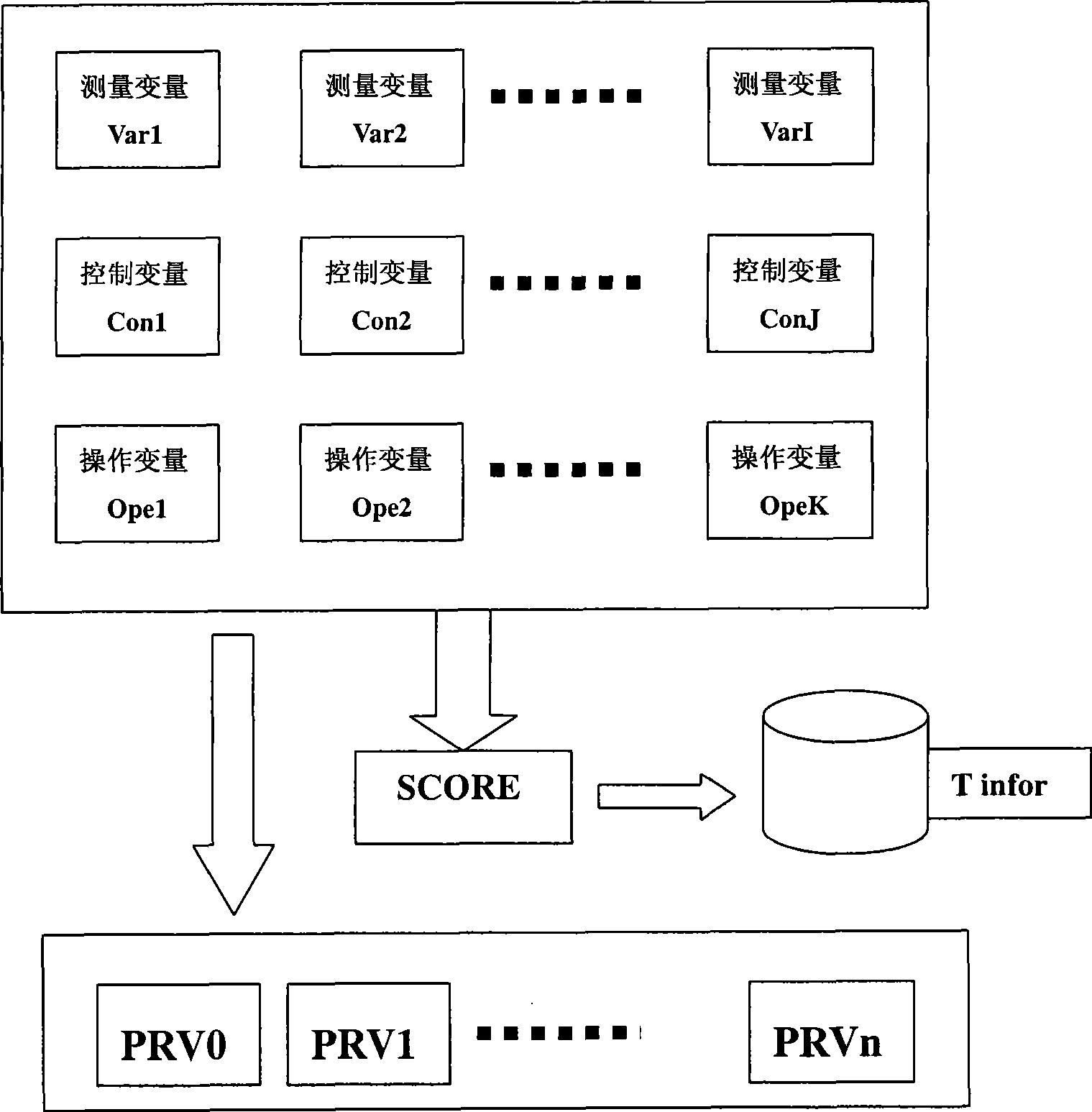

[0014] Establish the database of measured variables, control variables and operational variables in the process, respectively Var (measured variable), Con (controlled variable), Ope (operated variable), as shown in the figure. On this basis, the principal component model Score is established, and the extraction of the principal component fault mixed information T infor, fault information extraction and feature matching are carried out.

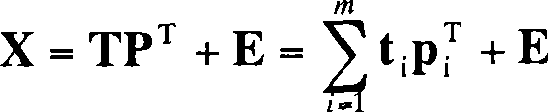

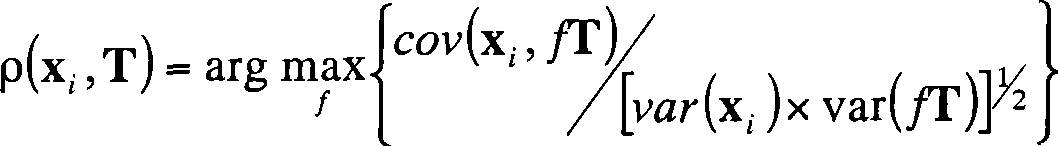

[0015] Establish process measurement variables, control variables, and operating variable databases, and extract the fault information of the principal component; complete the establishment of abnormal sub-domains based on the analysis of variables and the relevant information of the principal components; through abnormal sub-domain variables and the main component The correlation analysis of meta-fault information determines the fault source an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com