Samarium - cobalt magnetic powder and preparation thereof

A magnetic powder and powder technology, which is applied in the field of anisotropic samarium-cobalt magnetic powder and its preparation, can solve the problems that do not involve the chemical composition of SmCo magnetic powder SmCo magnetic powder, etc., and achieve the effect of no component segregation, uniform particle size and high proportion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

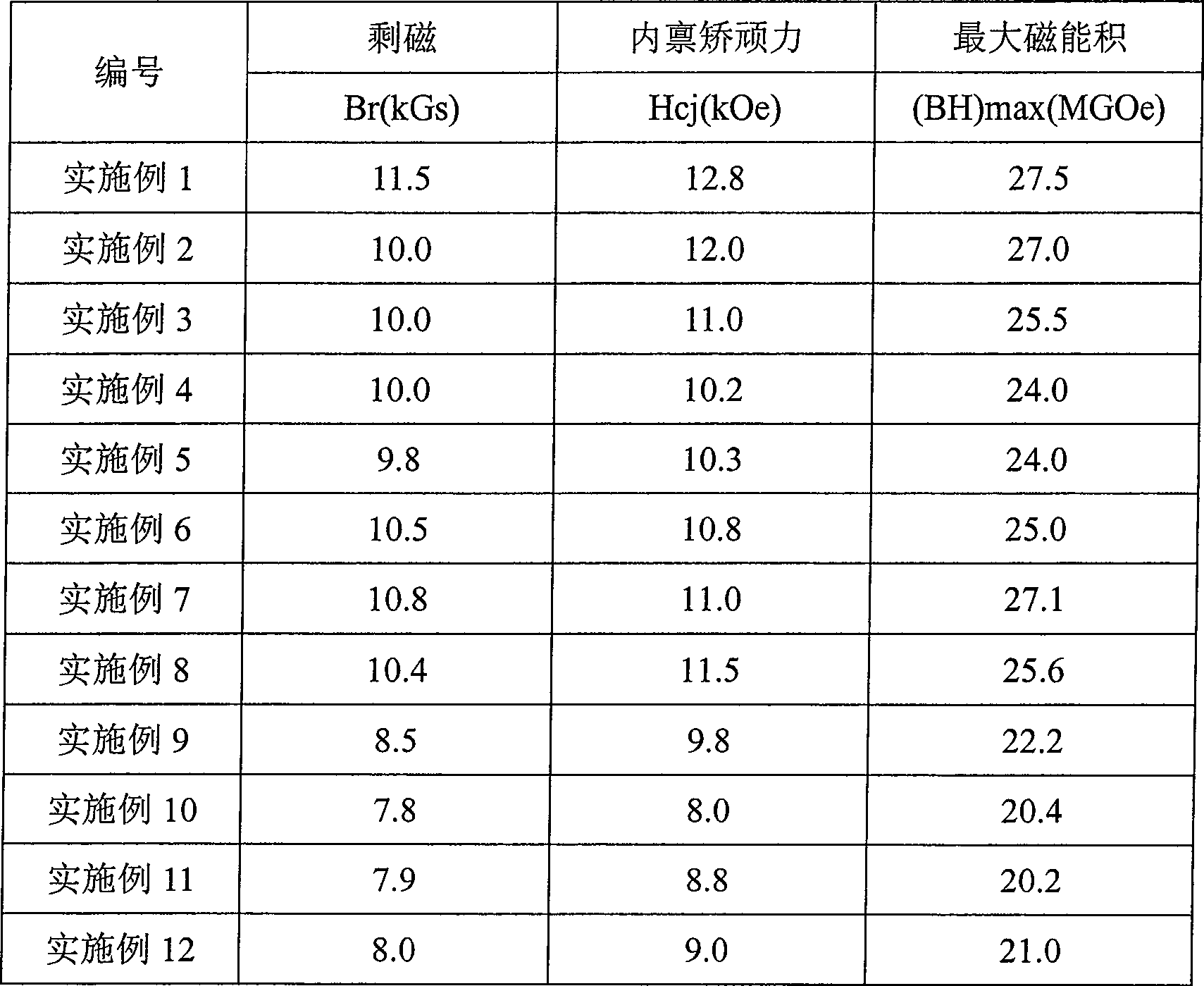

Embodiment 1

[0035] According to the composition of Sm: 24wt%, Cu: 6wt%, Fe: 16wt%, Zr: 4wt%, Co: 50wt%, put the prepared raw materials into the alumina crucible, and evacuate to less than 8×10 -3 Pa, fill in an appropriate amount of inert protective gas, melt the alloy by induction heating, and then cast the alloy liquid on a rotating water-cooled copper roller at a certain speed to prepare a 0.3mm thick samarium cobalt cast sheet.

[0036] Heat-treat the cast sheet, vacuum pretreatment at 700°C for 100 minutes; then under the protection of argon, undergo solution treatment at 1150°C for 300 minutes and then cool to room temperature; then keep the product at 810°C for 15 hours, and then cool to 400°C. Keep warm for 10 hours and cool to room temperature.

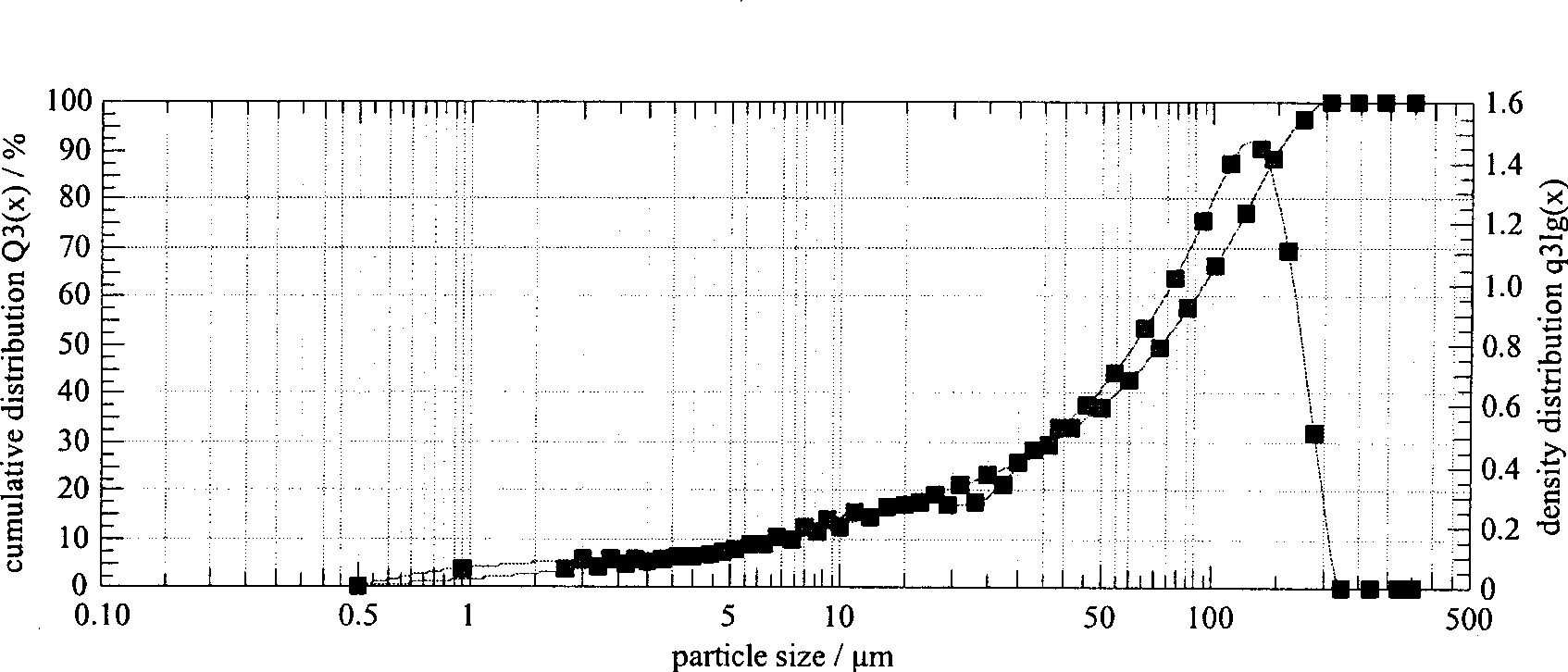

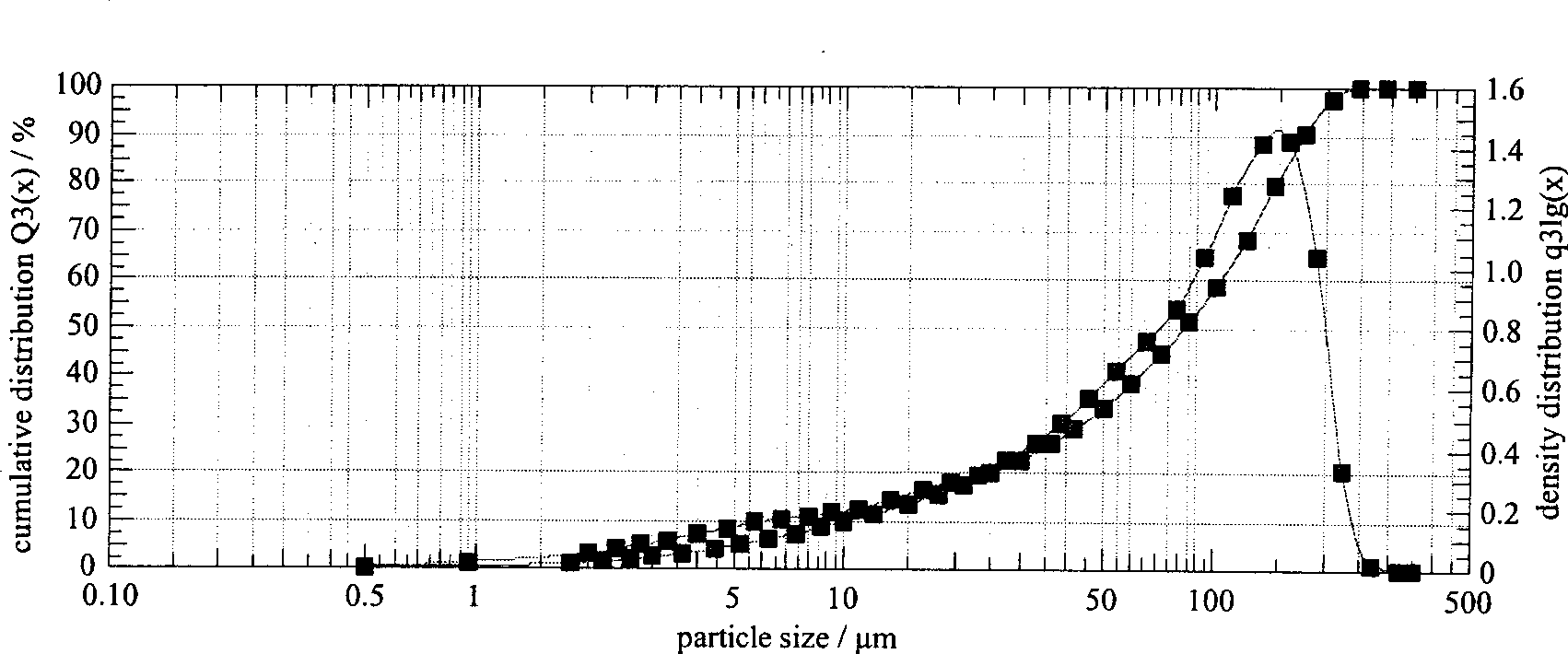

[0037] Coarsely crush the heat-treated cast pieces into 3-5mm particles, and then hydrogen-explode into powder. Hydrogen absorption process: at 100-300°C, hydrogen pressure>0.1pa, hydrogen absorption 1-3h; dehydrogenation process: heatin...

Embodiment 2

[0041] The raw materials are formulated as follows: Sm: 26.5wt%, Cu: 6.2wt%, Fe: 14wt%, Zr: 3.4wt%, Ni: 0.1wt% Co: 49.8wt%. The purity of each element is 99.9%. Add the prepared raw materials into the crucible, and evacuate to less than 8×10 -3 Pa, fill in an appropriate amount of inert protective gas, melt the alloy by induction heating, and then cast the alloy liquid on the rotating water-cooled plate at a certain speed to form an ingot with a thickness of 8mm.

[0042] The ingot is heat-treated and vacuum pretreated at 1000°C for 30 minutes; then it is solution treated at 1150°C for 200 minutes under the protection of argon and then cooled to room temperature; then the product is kept at 830°C for 8 hours, and then cooled to 350°C. Keep warm for 8 hours and cool to room temperature.

[0043] After the heat treatment, the samarium cobalt ingot is coarsely crushed into 3-5mm particles, and then ball milled and jet milled to obtain a powder with a particle size of 50-200 μm ...

Embodiment 3

[0046] The raw materials are formulated as follows: Sm: 23.0wt%, Cu: 7.2wt%, Fe: 16wt%, Zr: 3.5w%, Ti: 0.5wt%, Co: 49.8wt%. The purity of each element is 99.9%. Add the prepared raw materials into the alumina crucible, and evacuate to less than 8×10 -3 Pa, fill in an appropriate amount of inert protective gas, melt the alloy by induction heating, and then cast the alloy liquid on a rotating water-cooled copper roller at a certain speed to prepare a 0.1mm thick samarium cobalt cast sheet.

[0047] Heat-treat the cast piece, vacuum pretreatment at 800°C for 120 minutes; then, under the protection of argon, undergo solution treatment at 1170°C for 60 minutes and then cool to room temperature; then keep the product at 820°C for 9 hours, and then cool to 450°C. Keep warm for 12 hours and cool to room temperature.

[0048] After the heat treatment, the samarium cobalt ingot is roughly crushed into 3-5mm particles, and then ball milled and jet milled to obtain 60% of the total weig...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com