Quasi-blackbody absorbent high-efficient concentration solar cell assembly

A solar cell and absorption type technology, which is applied in the field of solar energy utilization, can solve the problems of reduced service life of grid lines, heating of grid lines, inconvenient use, etc., and achieves the effects of high concentration multiple, high heat dissipation efficiency, and reduced manufacturing cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

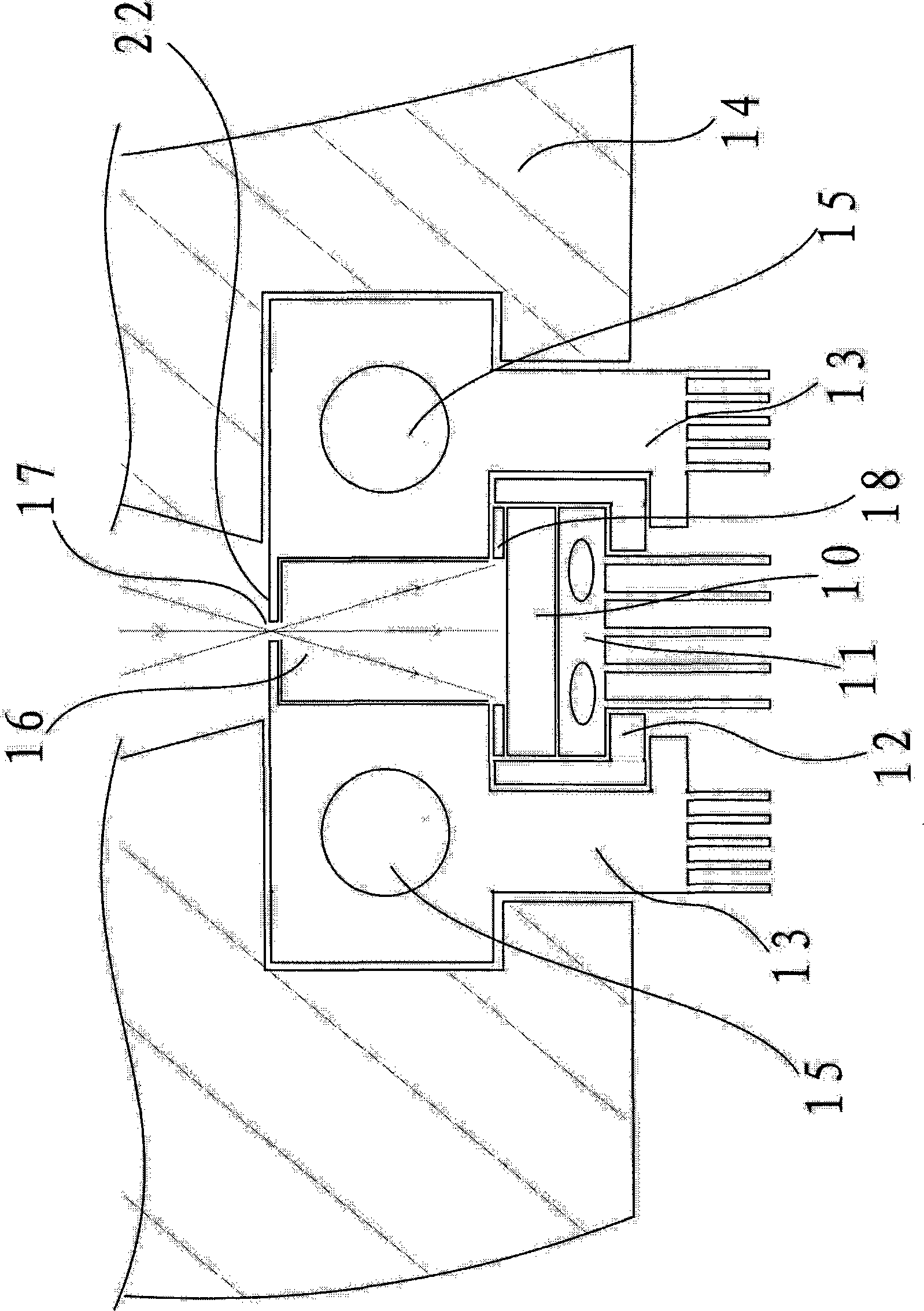

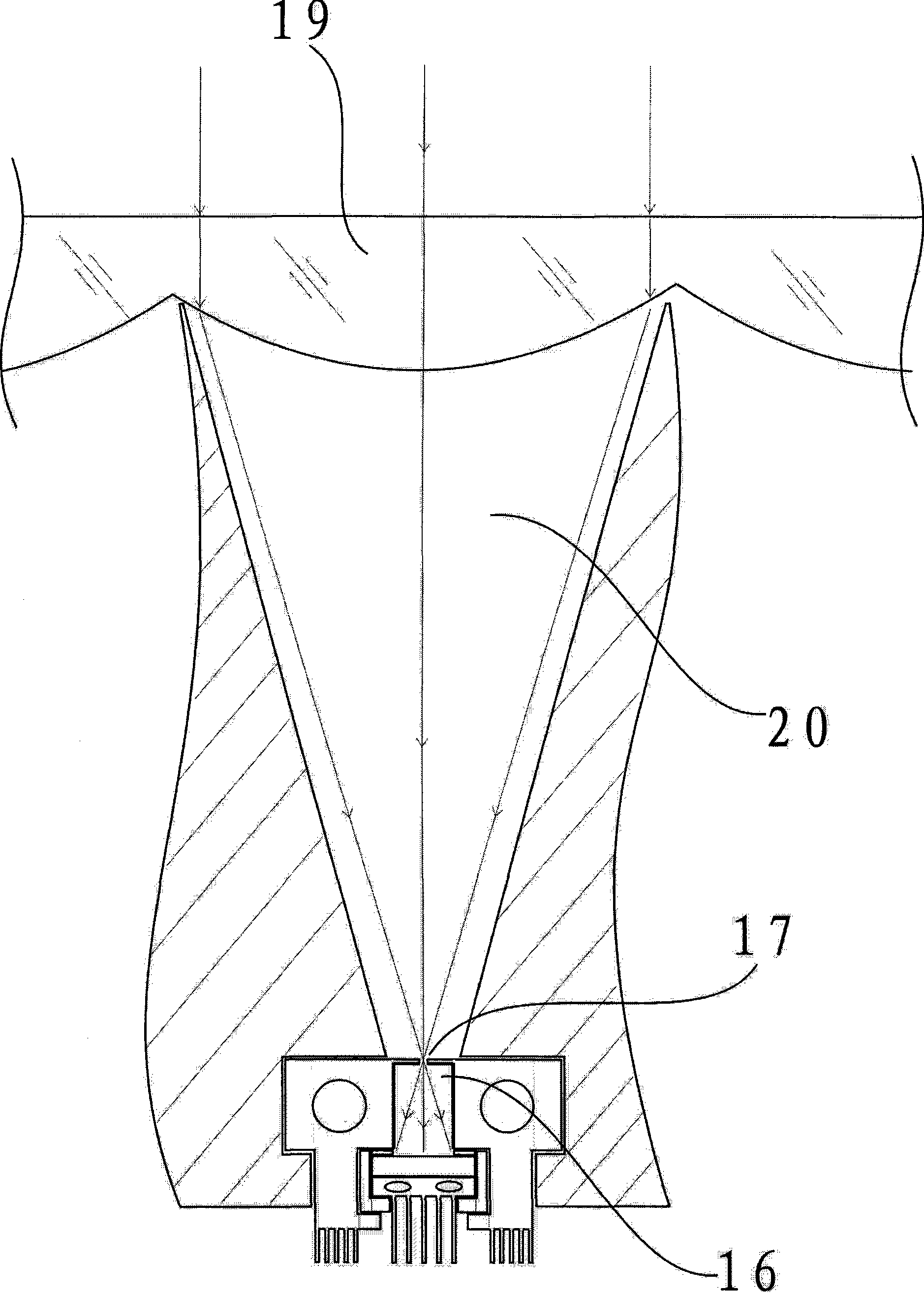

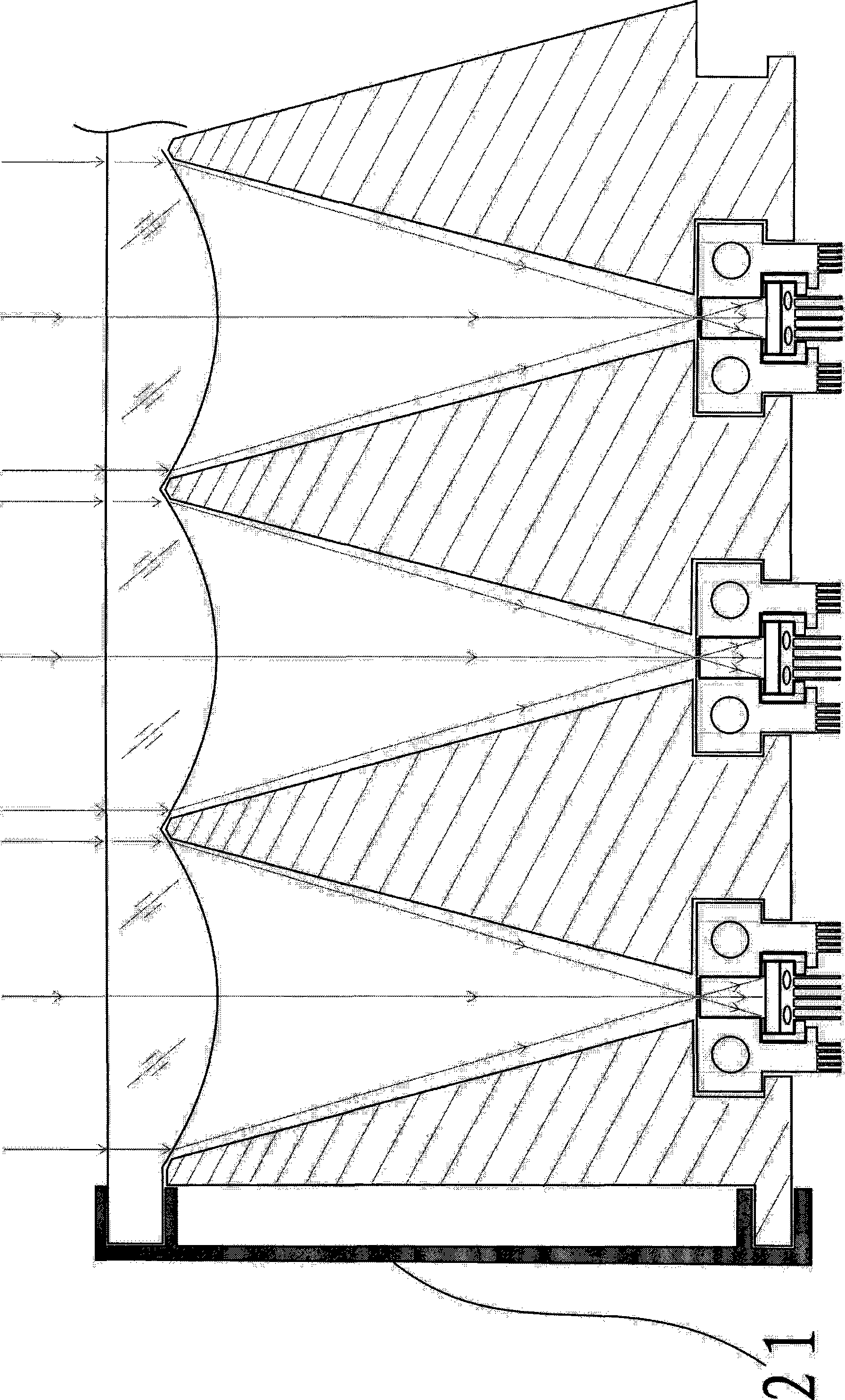

[0018] Such as figure 1 , figure 2 , image 3 As shown, the present invention provides a quasi-black body absorption type high-efficiency concentrating solar cell assembly, which mainly consists of a silicon cell 10, a back heat sink 11, an adhesive 12, a conductive heat dissipation metal member 13, an internal support 14, a flexible contact electrode 18, Strip lens array board 19 and packaging frame 21 . Among them, the silicon battery 10 is in the shape of a long and thin strip, and there are flexible contact electrodes 18 packaged with good electrical conductivity on both sides of the front of the silicon battery 10. The back is packaged with a back heat sink 11, and there is a cavity 16 coated with an internal reflection layer between the focus point formed by the strip lens array plate 19 and the upper surface of the silicon battery 10. There is a strip-shaped opening on the cavity 16, just It is located at the focus point formed by the strip lens array plate 19 , and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com