Carbon nano-tube composite material and preparation method thereof

A carbon nanotube, composite material technology, applied in nanotechnology, nanotechnology, chemical instruments and methods, etc., can solve the problems of difficult solvent removal, complex process, high cost, reduce production costs, simplify the preparation process, and ensure complete sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

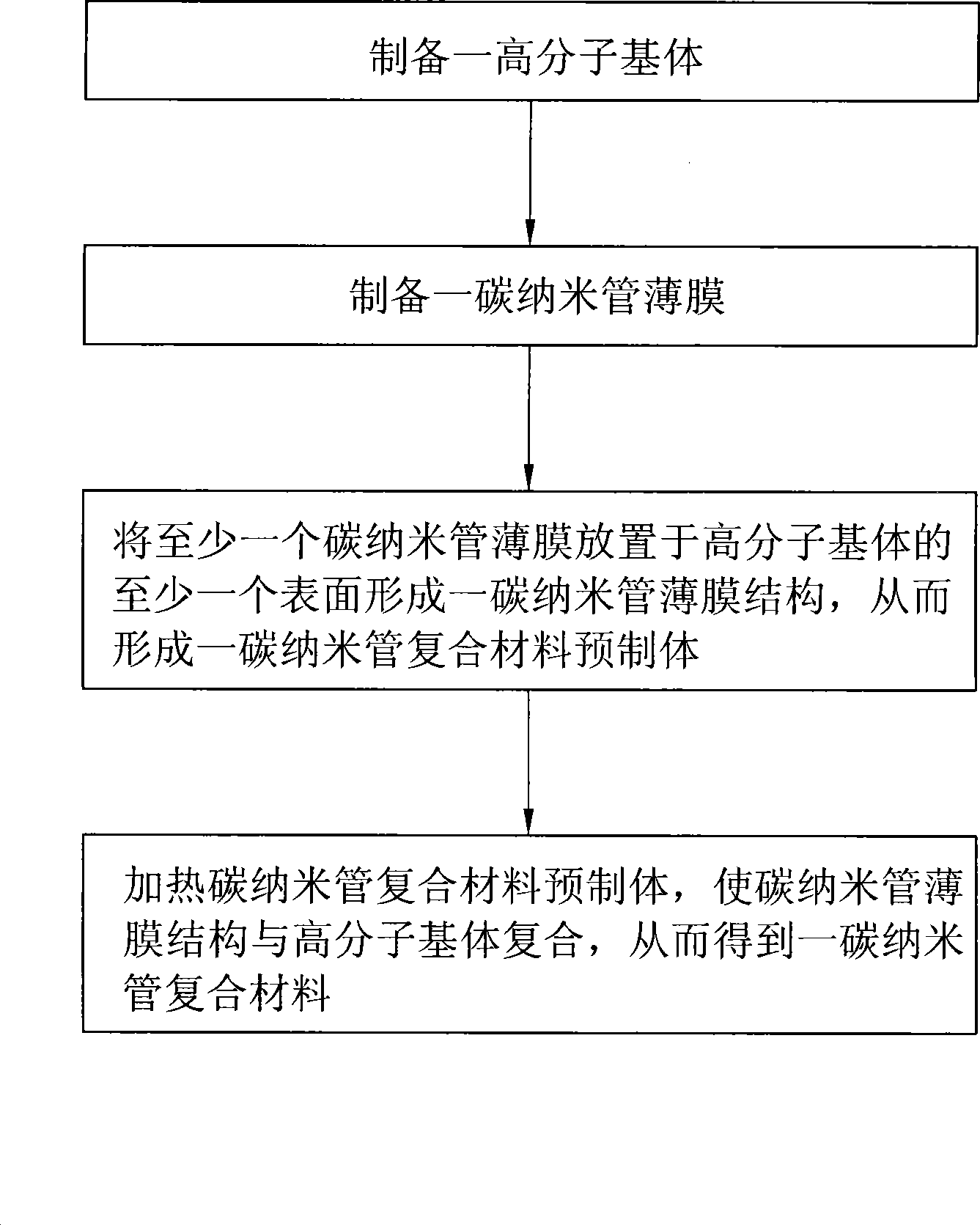

[0022] Please refer to image 3 , the technical solution also provides a method for preparing the above-mentioned carbon nanotube composite material 10, which specifically includes the following steps:

[0023] Step 1: preparing a polymer matrix 14 which is a polymer film.

[0024] The polymer matrix 14 can be prepared by solution film formation, hot-melt scraping coating, casting film formation and spray coating film formation.

[0025] In this embodiment, the polymer matrix 14 is prepared by hot-melt knife coating, which specifically includes the following steps: first, put liquid allylphenol in a container, heat it to 90-180°C, keep the container at this temperature and stir several minutes. Secondly, add bismaleimide powder into liquid allyl phenol, the mass ratio of bismaleimide to allyl phenol is in the range of 60:5-60:70, and the temperature of the container is controlled at 110-160 Within the range of ℃, let it stand still and keep the container at the temperature,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com