a fast growing sno 2 nanosheet approach

A nanosheet, fast technology, applied in nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve the problems of long nanosheet time, poor size uniformity of nanosheets, etc., and achieve low preparation cost and uniformity Good performance and stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] A fast growing SnO 2 A method for nanosheets, comprising the steps of:

[0028] S1), preparation of growth solution

[0029] S101), 0.118g of stannous chloride and 0.0678g of sodium acetate were added to 15mL of deionized water and magnetically stirred for 15min to obtain A solution;

[0030] S102), 0.072g of hexamethylenetetramine was added to 15mL of deionized water, and magnetically stirred for 15min to obtain B solution;

[0031] S103), mix the above-mentioned A solution and B solution evenly, and add 20mL of ethylene glycol, and then magnetically stir for 15min to prepare a uniform growth solution;

[0032] S2), substrate cleaning: use ethanol and deionized water to ultrasonically clean the ITO substrate for 5 times, and dry it;

[0033] S3), SnO 2 For the growth of nanosheets, put the prepared growth solution and clean ITO substrate into the autoclave, and keep it at 160°C for 1h;

[0034] S4), sample cleaning, using deionized water to ultrasonically clean th...

Embodiment 2

[0036] A fast growing SnO 2 A method for nanosheets, comprising the steps of:

[0037] S1), preparation of growth solution

[0038] S101), 0.15g of stannous chloride and 0.07g of sodium acetate were added to 15mL of deionized water and magnetically stirred for 15min to obtain A solution;

[0039] S102), 0.08g of hexamethylenetetramine was added to 15mL of deionized water, and magnetically stirred for 15min to obtain B solution;

[0040] S103), mix the above-mentioned A solution and B solution evenly, and add 20mL of ethylene glycol, and then magnetically stir for 15min to prepare a uniform growth solution;

[0041] S2), substrate cleaning: use ethanol and deionized water to ultrasonically clean the ITO substrate 8 times, and dry it;

[0042] S3), SnO 2 For the growth of nanosheets, put the prepared growth solution and clean ITO substrate into the autoclave, and keep it at 250°C for 0.5h;

[0043] S4), sample cleaning, using deionized water to ultrasonically clean the samp...

Embodiment 3

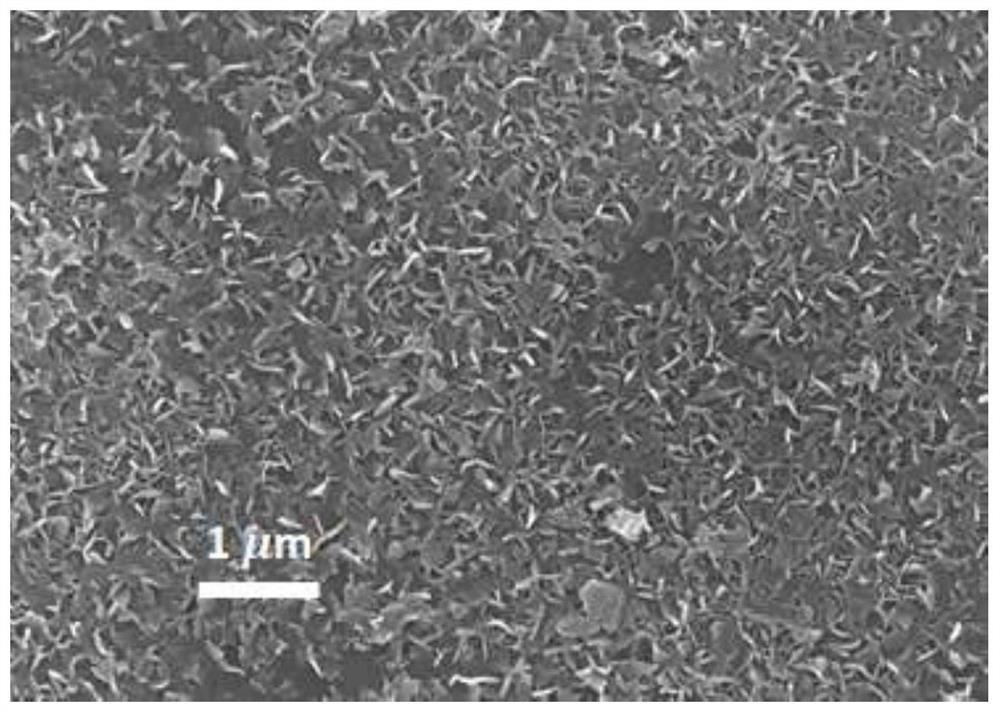

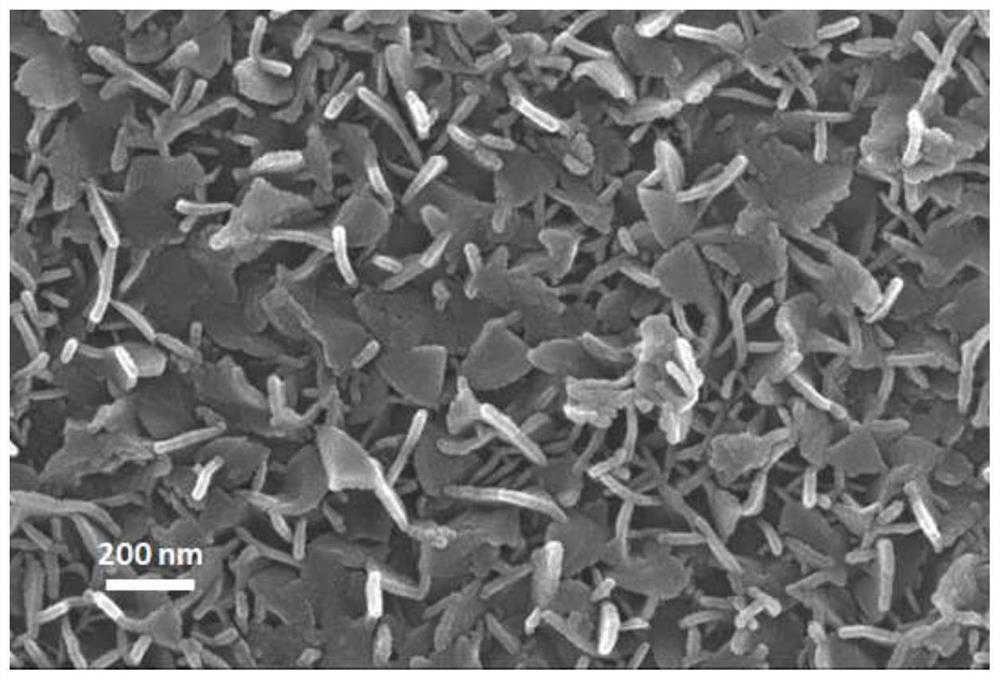

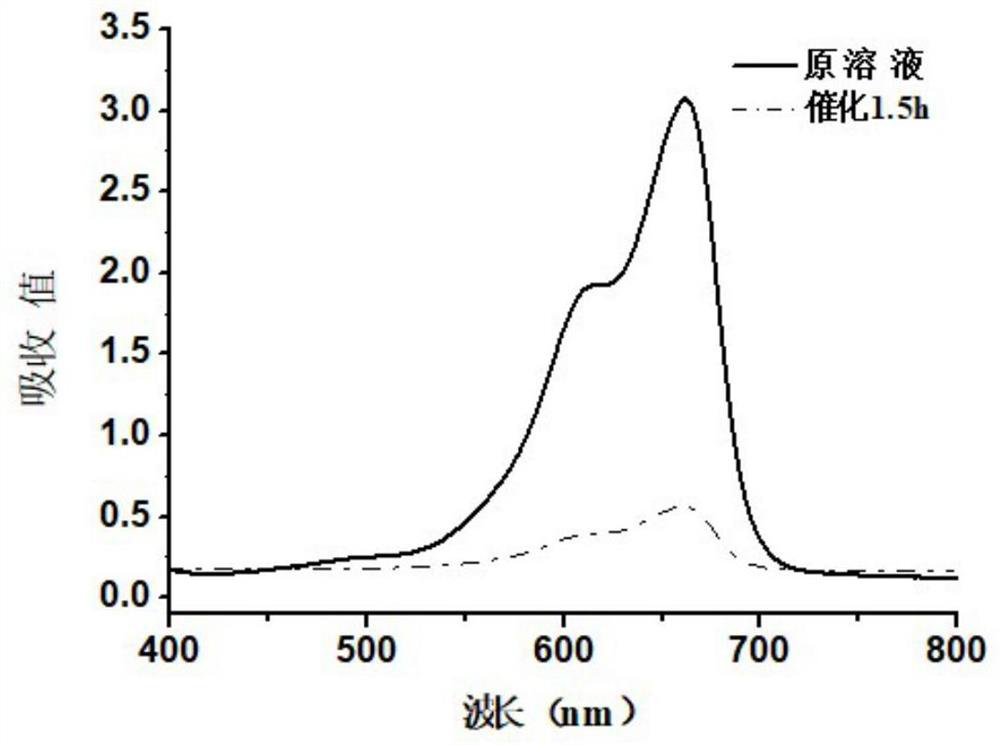

[0045] Such as figure 1 As shown, SnO 2 The nanosheets completely cover the substrate, and the distribution is relatively uniform, figure 2 It is the SnO of the embodiment of the present invention 1 The high power scanning electron microscope (SEM) photo of the nano sheet of preparation, as figure 2 As shown, SnO 2 The nanosheet has good uniformity, and its thickness is about 10nm. image 3 It is the SnO prepared by Example 1 of the present invention 2 The absorption spectrum of photocatalytic degradation of methylene blue by nanosheets, as shown in the figure, after 1.5h of photocatalytic degradation, the absorbance of methylene blue decreased from 3.06 to 0.25, which shows that SnO 2 Nanosheets have good photocatalytic degradation function.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com