Preparation method for material with self-lubricating property and lubricating self-regulation function and with LiPbAg-BC as regulation agent

A technology of functional materials and regulating agents, which is applied in the field of preparation of functional materials with self-lubricating properties and self-lubricating self-regulating properties using LiPbAg-BC as a regulating agent, can solve the problems of restricting wide application and poor friction and wear resistance, and achieve technological parameters The effects of stability, excellent anti-friction and anti-wear performance, excellent mechanical properties and thermodynamic properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

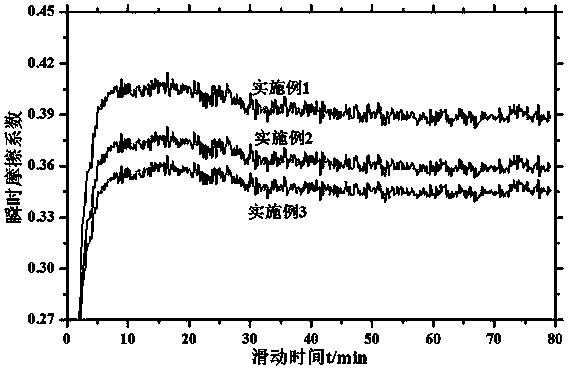

Embodiment 1

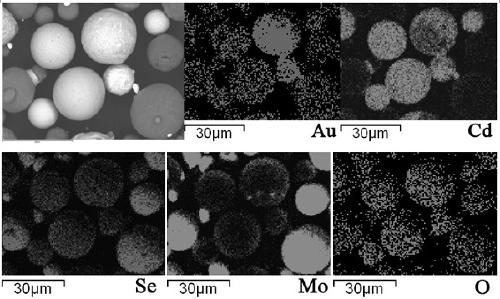

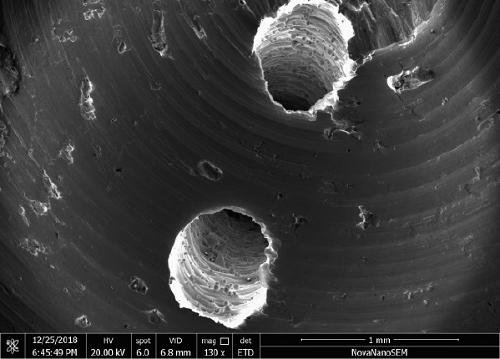

[0031] A material with self-lubricating properties and lubrication self-regulating function using LiPbAg-BC as a regulating agent. The mass ratio (wt.%) of the matrix TiNiAlZrNbSiMoY to the solid lubricating phase AuCdSe-MoO is 5:1. The element mass ratio (wt.%) of the matrix material is 10:16:6:5:3:0.45:0.4:0.3; the mass ratio (wt.%) of the solid lubricant phase AuCdSe to MoO is 5:1, and the mass ratio of the AuCdSe element ( wt.%) is 3:2:3, MoO element mass ratio (wt.%) is 1:2. The mass ratio (wt.%) of the matrix material to the regulator LiPbAg-BC is 2:0.1, the mass ratio (wt.%) of LiPbAg to BC is 20:3, and the atomic ratio (at.%) of LiPbAg is 2:3:5. BC atomic ratio (at.%) is 2:1;

[0032] Weigh Ti, Al, Zr, Nb, Si, Mo, Y elemental powders, Au, Cd, Se, MoO powders, and Li, Pb, Ag, BC powders according to the proportion, and use a vibrating mixer to mix the base material and solid lubrication. The phase and regulator are vibrated and mixed, the vibration frequency is 10Hz, ...

Embodiment 2

[0038] A material with self-lubricating properties and lubricating self-regulating function using LiPbAg-BC as a regulating agent. The mass ratio (wt.%) of the matrix to the solid lubricating phase AuCdSe-MoO is 1:2. The element mass ratio (wt.%) of the matrix material is 10:16:6:5:3:0.45:0.4:0.3; the mass ratio (wt.%) of AuCdSe to MoO in the solid lubricant phase is 10:3, and the mass ratio of AuCdSe element ( wt.%) is 3:2:4, MoO element mass ratio (wt.%) is 1:3. The mass ratio (wt.%) of the matrix material to the regulator LiPbAg-BC is 10:1, the mass ratio (wt.%) of LiPbAg to BC is 20:3, and the atomic ratio (at.%) of LiPbAg is 2:3:6. BC atomic ratio (at.%) is 1:1;

[0039] Weigh Ti, Al, Zr, Nb, Si, Mo, Y elemental powders, Au, Cd, Se, MoO powders, and Li, Pb, Ag, BC powders according to the proportion, and use a vibrating mixer to mix the base material and solid lubrication. The phase and the regulating agent are vibrated and mixed, wherein the vibration frequency is 50Hz...

Embodiment 3

[0045]A material with self-lubricating properties and lubrication self-regulating function using LiPbAg-BC as a regulating agent. The mass ratio (wt.%) of the matrix TiNiAlZrNbSiMoY to the solid lubricating phase AuCdSe-MoO is 10:9. The element mass ratio (wt.%) of the matrix material is 10:16:6:5:3:0.45:0.4:0.3; the mass ratio (wt.%) of AuCdSe to MoO in the solid lubricant phase is 1:2, and the mass ratio of AuCdSe element ( wt.%) is 3:2:5, MoO element mass ratio (wt.%) is 1:5. The mass ratio (wt.%) of the matrix material to the regulator LiPbAg-BC is 20:3, the mass ratio (wt.%) of LiPbAg to BC is 20:3, and the atomic ratio (at.%) of LiPbAg is 2:3:8. BC atomic ratio (at.%) is 2:3;

[0046] Weigh Ti, Al, Zr, Nb, Si, Mo, Y elemental powders, Au, Cd, Se, MoO powders, and Li, Pb, Ag, BC powders according to the proportion, and use a vibrating mixer to mix the base material and solid lubrication. Phases and regulators were vibrated and mixed, wherein the vibration frequency was ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com