Electricity-oil dual-power laneway loader-digger transmission separating mechanism and chassis driving device

A backhoe loader and transmission separation technology, which is applied to the arrangement of multiple prime movers of the power unit, the general power unit, and the air pressure power unit, etc., can solve the problems of high noise, low energy utilization rate, expensive fuel, etc. Achieve the effect of strong climbing ability and good passability of the whole machine

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

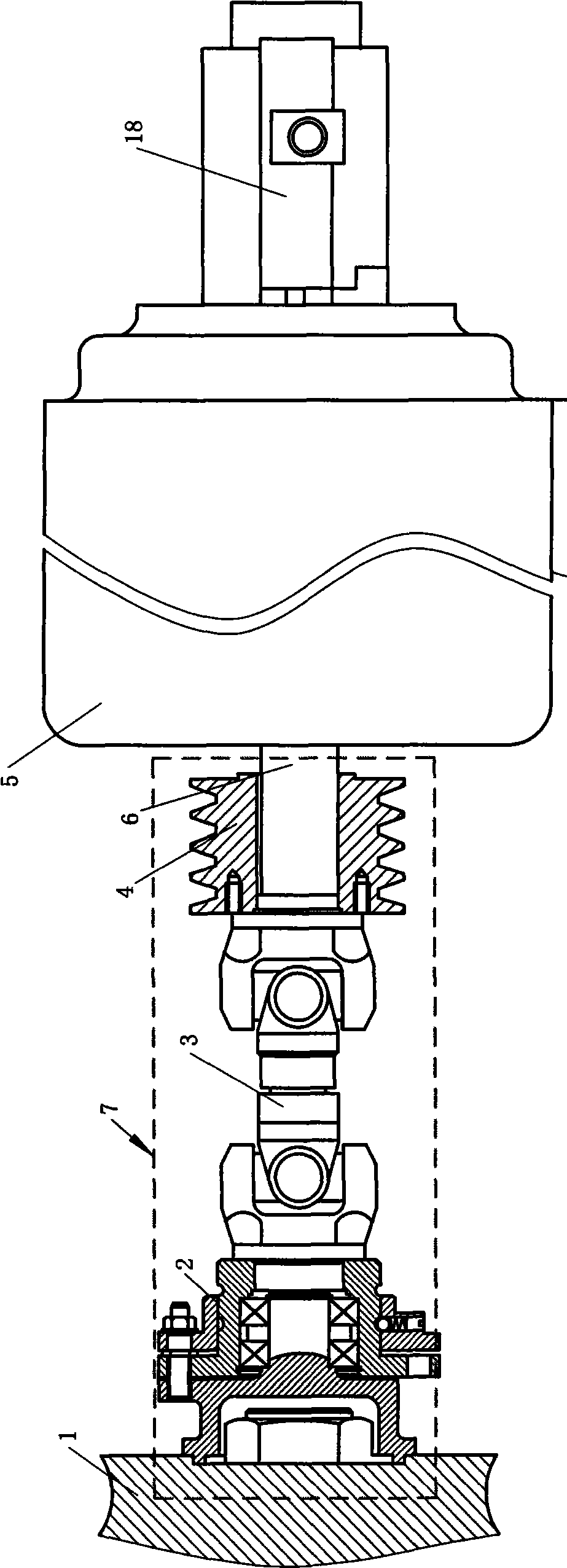

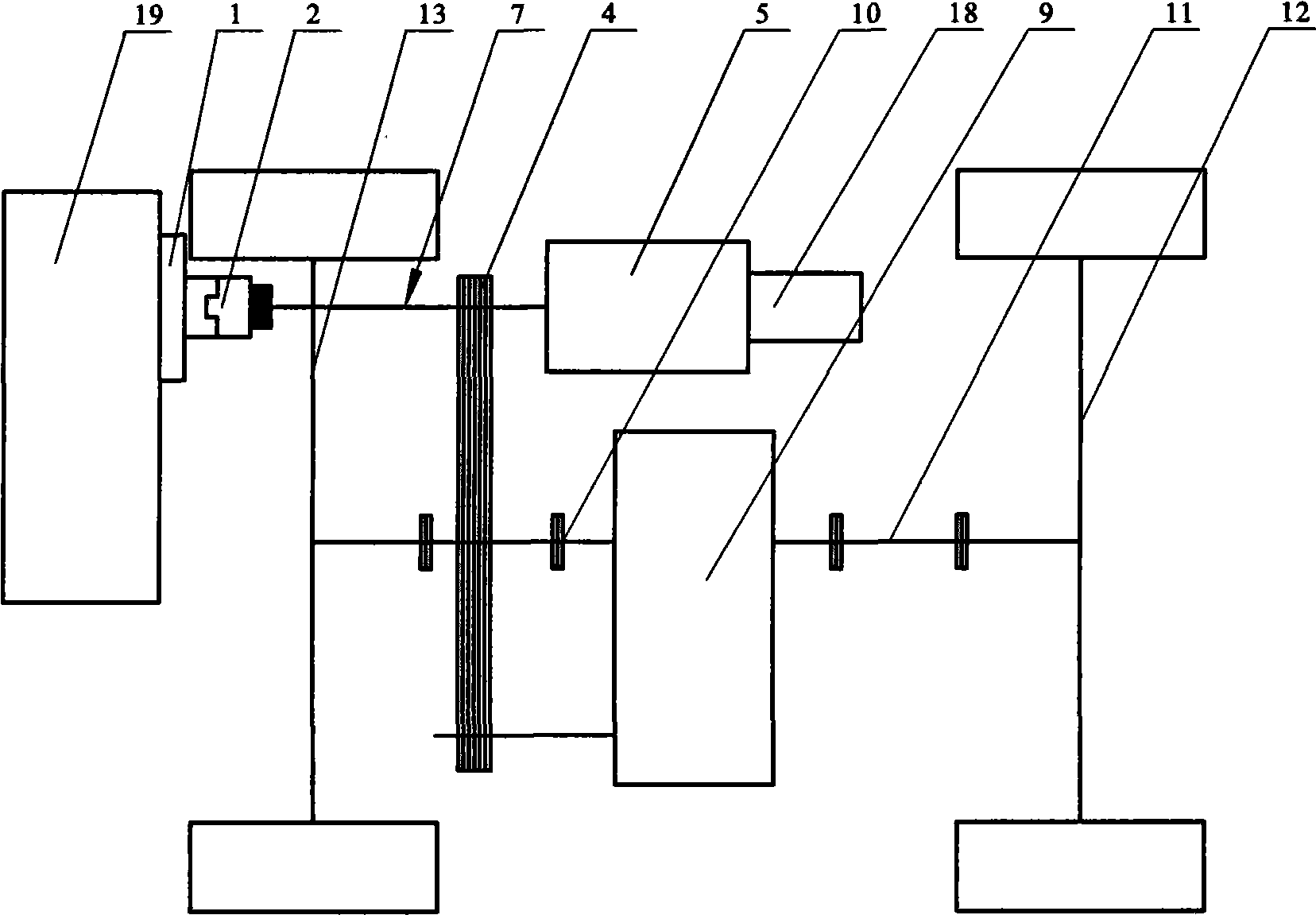

[0025] Embodiment one: see figure 1 , image 3 , an electric oil dual-purpose roadway backhoe loader transmission separation mechanism and chassis drive device, characterized in that the output shaft 1 of the internal combustion engine is coaxially connected with the output shaft 6 of the electric motor 5, and a transmission mechanism 4 is arranged on the coaxial. The coaxial shafts are connected through the cross coupling 3, which is beneficial to overcome the transmission quality affected by a certain swing amplitude caused by vibration and other reasons. In addition, a clutch 2 is also connected to the output shaft of the internal combustion engine 1 to ensure that the internal combustion engine is disconnected from the coaxial shaft in time when the internal combustion engine is not working, so as to facilitate the operation of the electric motor 5 . The above connection relationship is that the output shaft 1 of the internal combustion engine 19, the clutch 2, the Oldham...

Embodiment 2

[0026] Embodiment 2: The accompanying drawings are not drawn, and the meaning is basically the same as Embodiment 1, and the similarities will not be repeated. The difference is that a clutch is also provided between the driving shaft of the transmission mechanism and the output shaft of the motor. Compared with Embodiment 1, when the internal combustion engine is working (when driving the locomotive), it can be disconnected from the output shaft of the motor, and when the motor starts to work, it is guaranteed that the output shaft at one end of the motor or the output shaft at the other end directly drives the transmission. Institutions get to work. The gear pump can be connected with the output shaft at the other end of the motor or can be connected with the coaxial transmission.

Embodiment 3

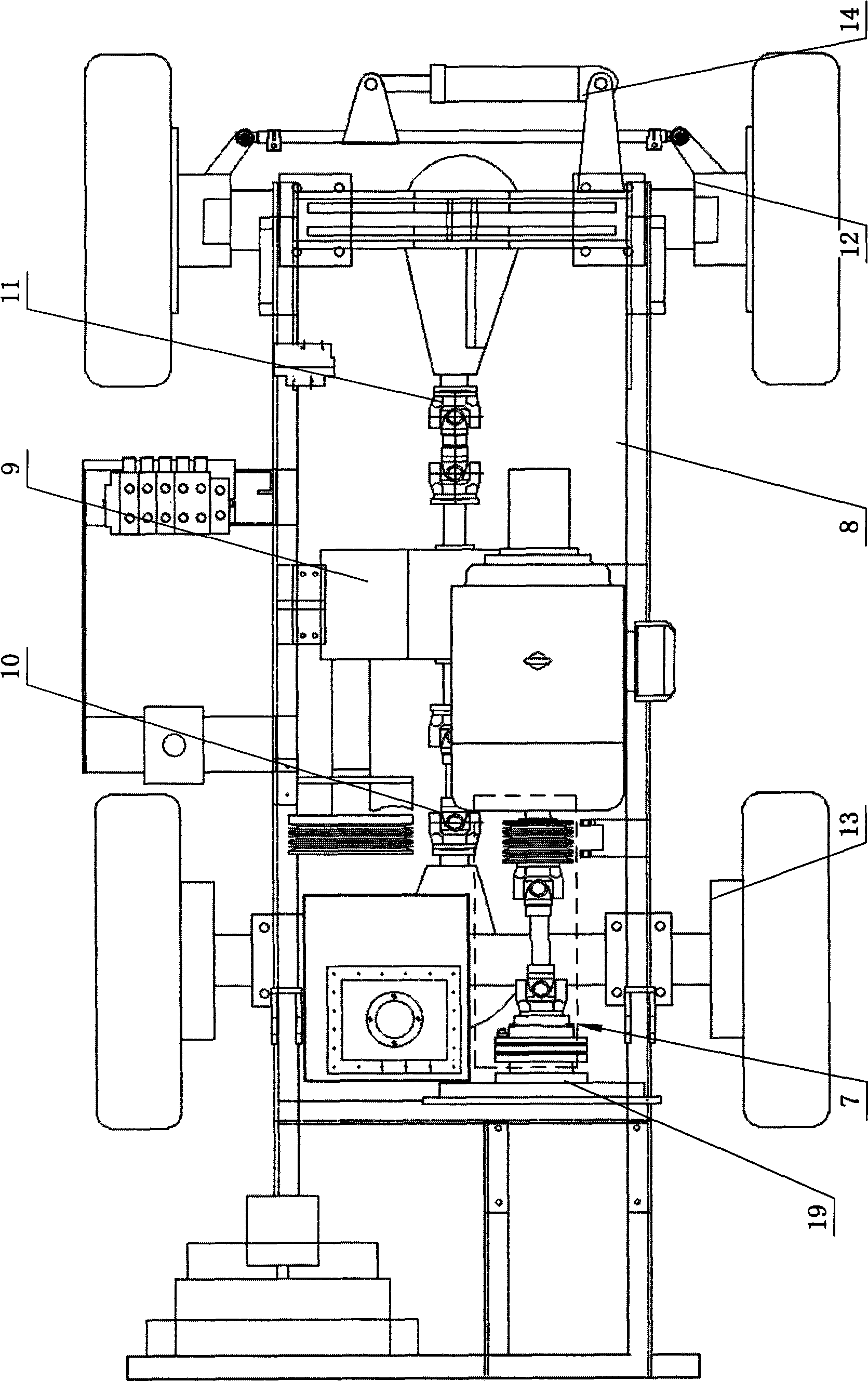

[0027] Embodiment three: see figure 1 , figure 2 , image 3 , Figure 4 , a chassis driving part of an electric-oil dual-purpose roadway backhoe loader, including a chassis 8, a driving mechanism positioned on the chassis 8, a transmission mechanism 4, front and rear axles 12, 13 and wheels installed on both sides thereof, the driving mechanism It includes a power unit, a clutch 2 and a gearbox 9, wherein the power unit is a coaxial dual-power driving machine composed of an electric motor 5 and an internal combustion engine 19, that is, the internal combustion engine 19 is coaxially connected with the electric motor 5, and a transmission mechanism ( Pulley) 4. Internal combustion engine 19 (such as diesel engine) on the complete machine chassis 8 is used for the power of hydraulic pressure walking, drives clutch 2, power transmission shaft (coaxial), motor pulley 4 and motor 5 by internal combustion engine, and motor pulley 4 is connected the pulley of gearbox 9, thereby m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com