Color temperature-adjustable high-color development LED lamp and manufacturing method thereof

A technology for an LED lamp and a manufacturing method, which is applied to parts of lighting devices, semiconductor devices of light-emitting elements, optical elements used to change the spectral characteristics of emitted light, etc. Brightness and other issues, to achieve high brightness, reduce consumption, improve brightness and color rendering index

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

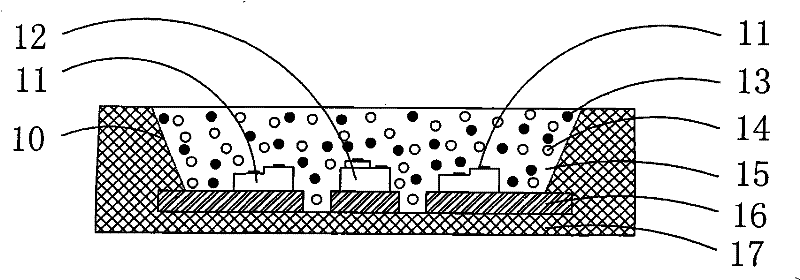

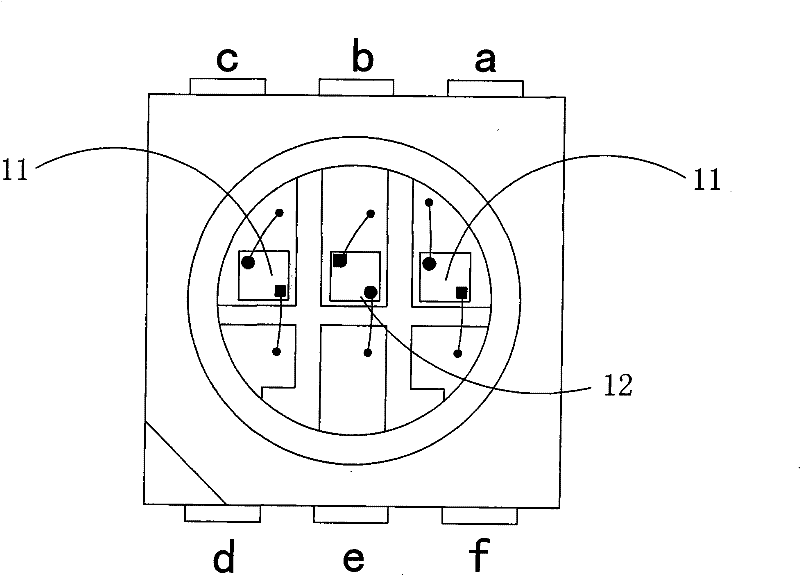

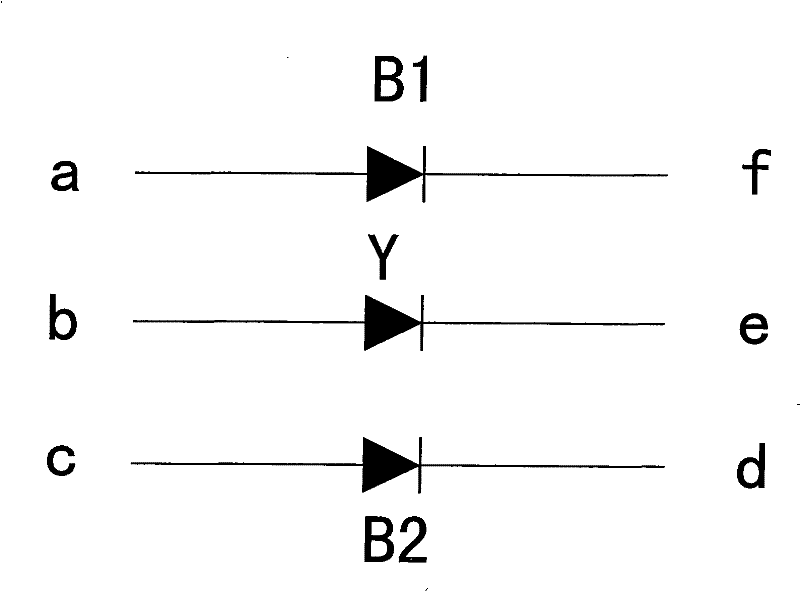

[0022] Please refer to figure 1 and figure 2 , which are respectively a schematic cross-sectional view and a schematic structural view of an embodiment of the LED lamp provided by the present invention; as shown in the figure, this embodiment mainly includes:

[0023] There is a cavity 10 in the encapsulation material 17 and two blue light chips 11 and at least one yellow light chip 12 placed at the bottom of the cavity 10. Red phosphor 13, green phosphor 14 and glue 15 form a phosphor, which is filled in Inside the chamber 10.

[0024] The bottom of the chamber 10 is provided with a metal lead frame 16 for fixing the LED chip; and the lead frame 16 is provided with at least two blue light chips 11 and one yellow light chip 12, and the yellow light chip 12 is fixed in the middle of the blue light chip 11 . The bottom layer of the yellow light chip 12 is a transparent substrate.

[0025] The glue 15 is silica gel or silicone resin or epoxy resin; and the encapsulation mat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com