Take up type vacuum vapor deposition device

A winding-type, vacuum technology, applied in the direction of vacuum evaporation plating, sputtering plating, ion implantation plating, etc., can solve the problems of reduced cooling effect, weak adhesion force, insufficient irradiation of film 52, etc., to prevent Effect of generation of heat-affected area and prevention of reduction of cooling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Embodiments of the present invention will be described below with reference to the drawings.

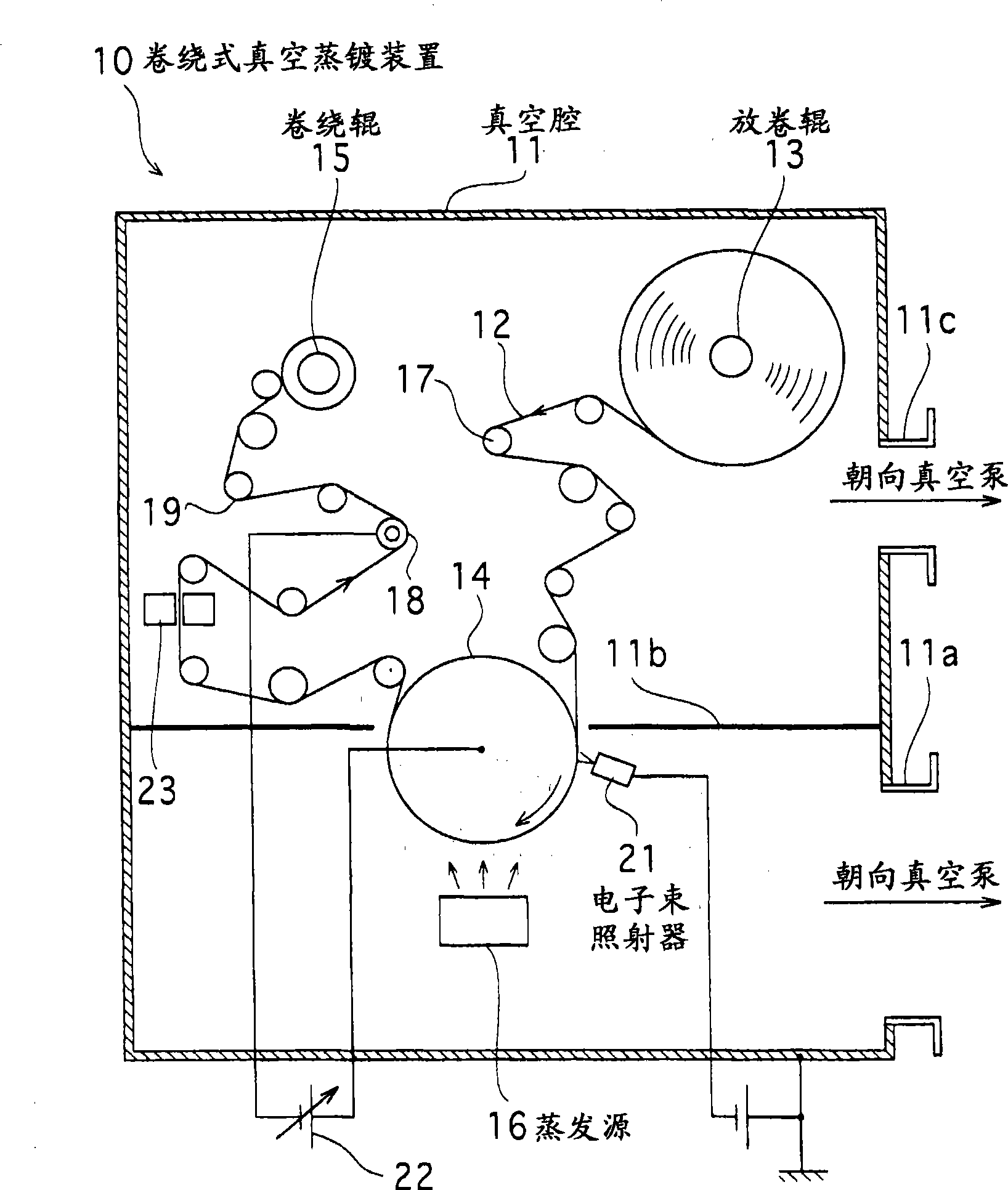

[0029] figure 1 It is a schematic configuration diagram of the roll-to-roll vacuum deposition apparatus 10 in the embodiment of the present invention. The roll-to-roll vacuum evaporation device 10 in this embodiment includes a vacuum chamber 11 , an unwinding roll 13 for a film 12 , a barrel roll 14 for cooling, a winding roll 15 and an evaporation source 16 for an evaporation material.

[0030] The vacuum chamber 11 is connected to a vacuum exhaust system such as a vacuum pump (not shown) through pipe connection portions 11a and 11c, and its interior is decompressed and exhausted to a predetermined vacuum degree. The inner space of the vacuum chamber 11 is partitioned by a partition 11 b into a chamber in which the unwinding roll 13 and the winding roll 15 are disposed, and a chamber in which the evaporation source 16 is disposed.

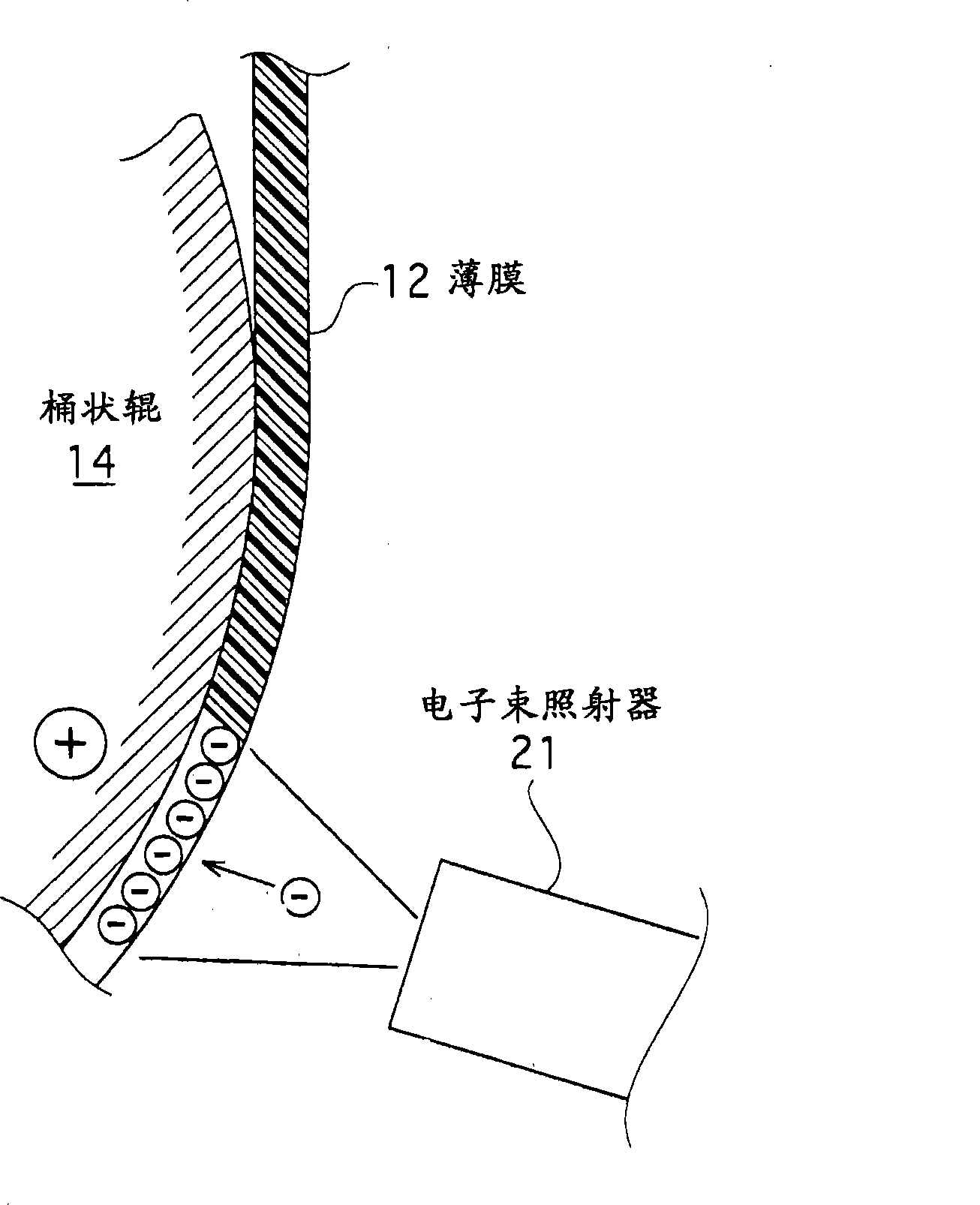

[0031] The film 12 is made of an insulat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com