Multi-structured light binocular composite vision weld joint tracking method and device

A tracking device, multi-structure technology, used in auxiliary devices, welding equipment, welding equipment and other directions, can solve the problems of low precision, unable to eliminate leading errors, poor anti-interference ability, etc., to eliminate leading errors and improve anti-interference. Performance, compact effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

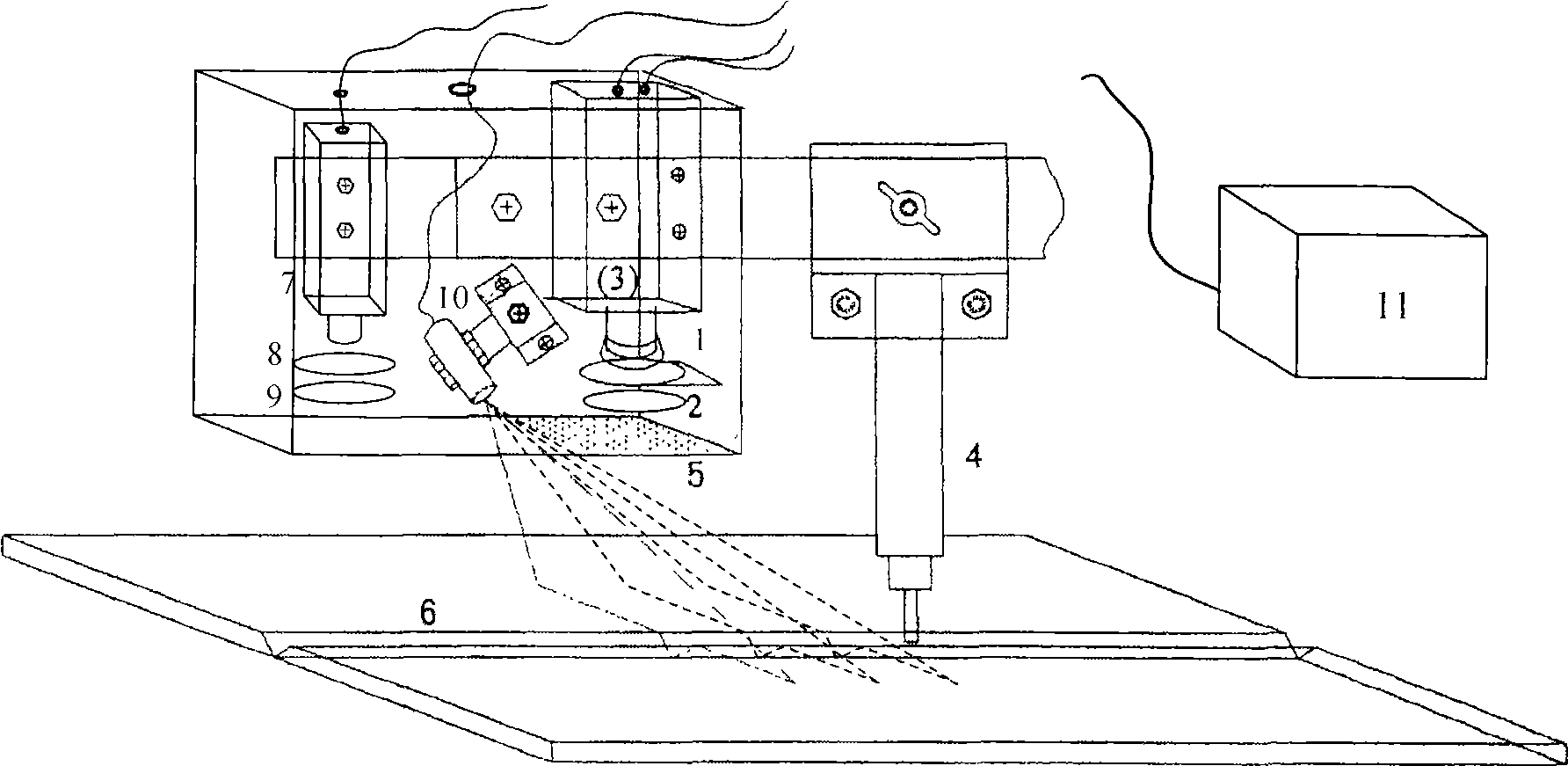

[0017] Such as figure 1 As shown, the multi-structured light composite visual welding seam tracking device of the present invention includes a narrow-band filter 1, a neutral light-reducing film A, a camera A, a splash guard 5, a camera B, and a band-pass filter 8 (which can transmit light wave with a wavelength of 650nm), a neutral light reduction film B, a multi-line laser 10, and a controller 11. Both cameras are industrial cameras. Among them, the laser and the camera are packaged together, and are rigidly connected to a frame with the welding torch 4. The camera head is equipped with a light reduction sheet and a light filter, and the welding seam tracking device is fixedly connected to the welding torch. The plane intersects the plane formed by the welding seam and is perpendicular to the surface of the workpiece to be welded; the camera is connected to the controller cable through the signal line.

[0018] Above-mentioned controller 11 comprises computer and parts the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com