Method for manufacturing ceramic massage device

A production method and technology of a massager, applied in the direction of an instrument that compresses reflex points, can solve problems such as adverse effects on the skin, easy dryness, and insufficient smoothness, and achieve the effect of strong greasy feeling, large heat capacity, and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Below by example, in conjunction with accompanying drawing, can do further understanding to the present invention.

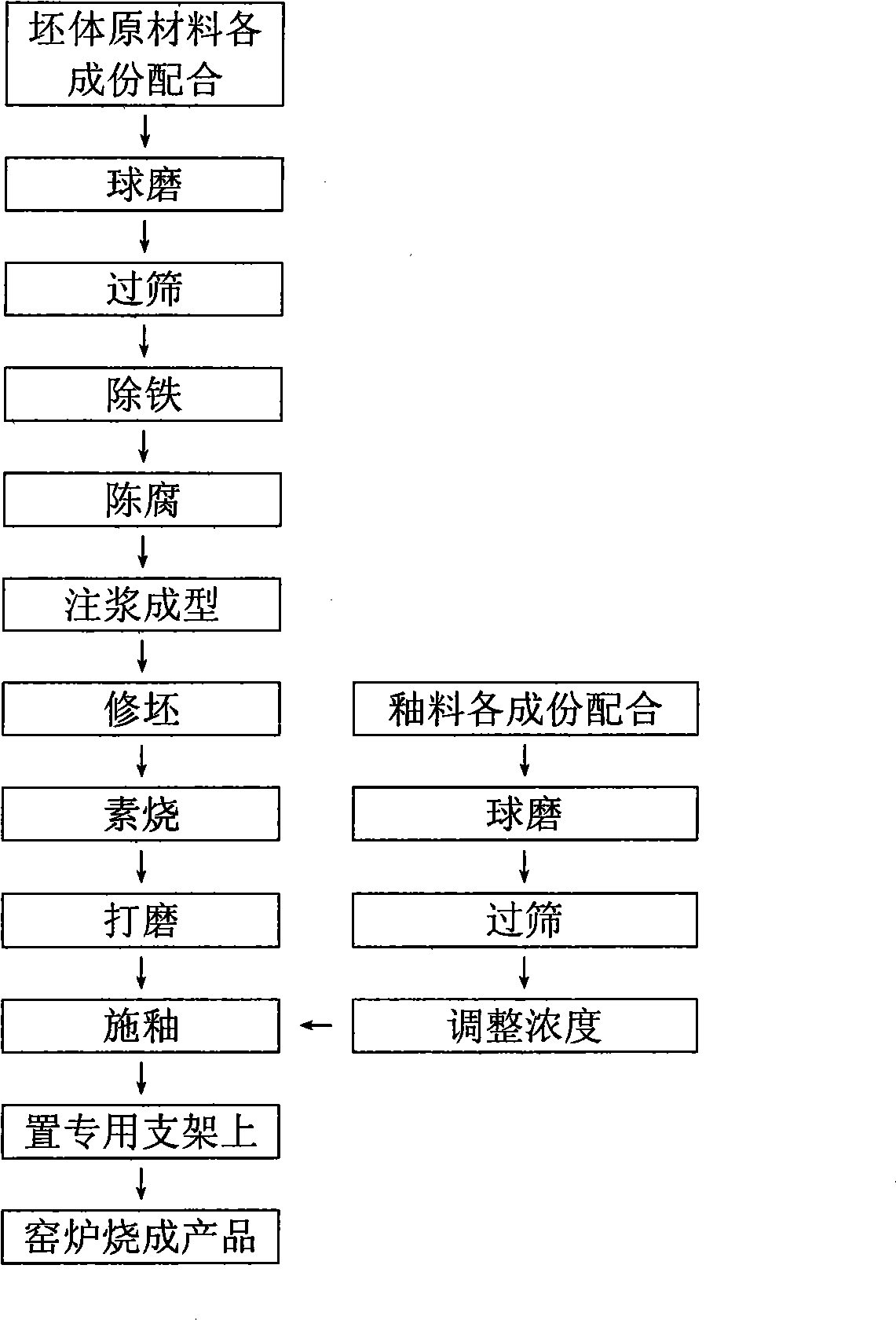

[0018] A method for manufacturing a ceramic massager, the method comprising the steps in the following order:

[0019] 1. Selection of porcelain clay, its main components are as follows: 70% talcum powder, 10% feldspar, 8% black clay, 5% kaolin washing mud, 3% quartz powder and 4% marble powder.

[0020] 2. Production of billet: The raw materials of the billet are weighed and mixed according to the above-mentioned formula design, and then ball milled for 22 hours with the ratio of material, ball and water: 1:1.6:0.7, and then sieved with a million-hole sieve, the fineness The sieve residue is 0.3%. After the iron removal process, it will be stale for 7 days.

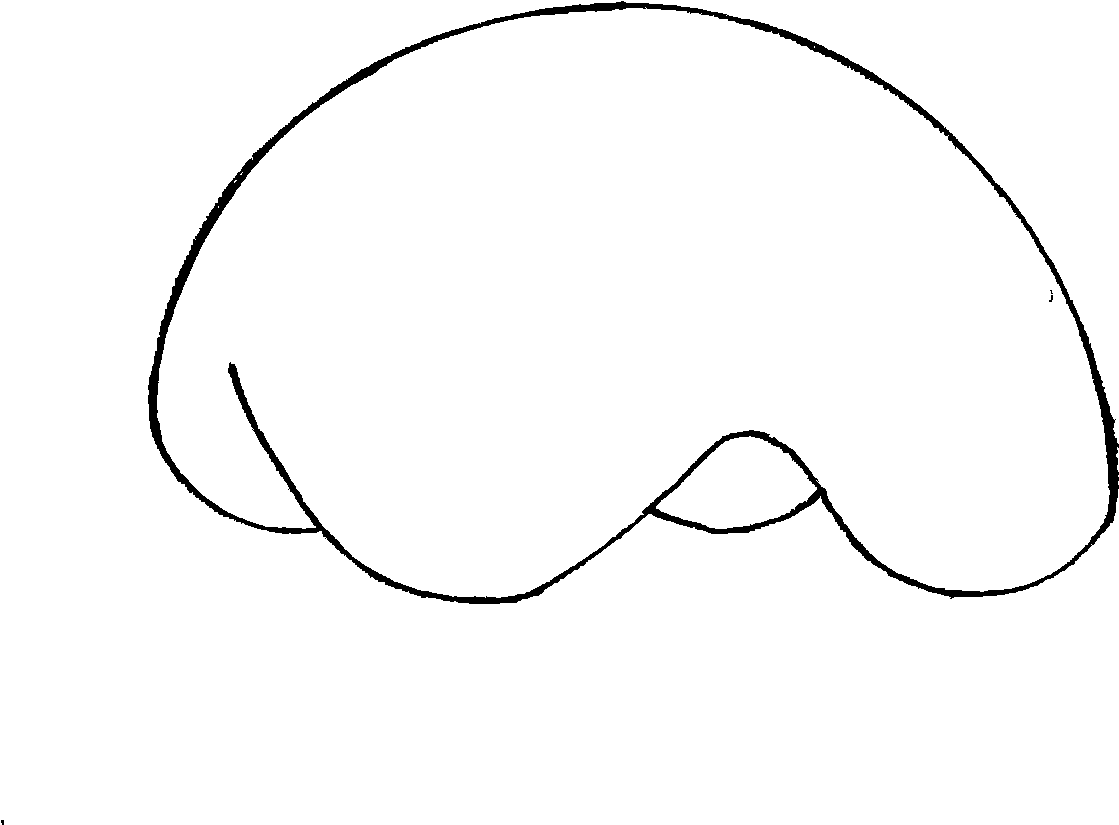

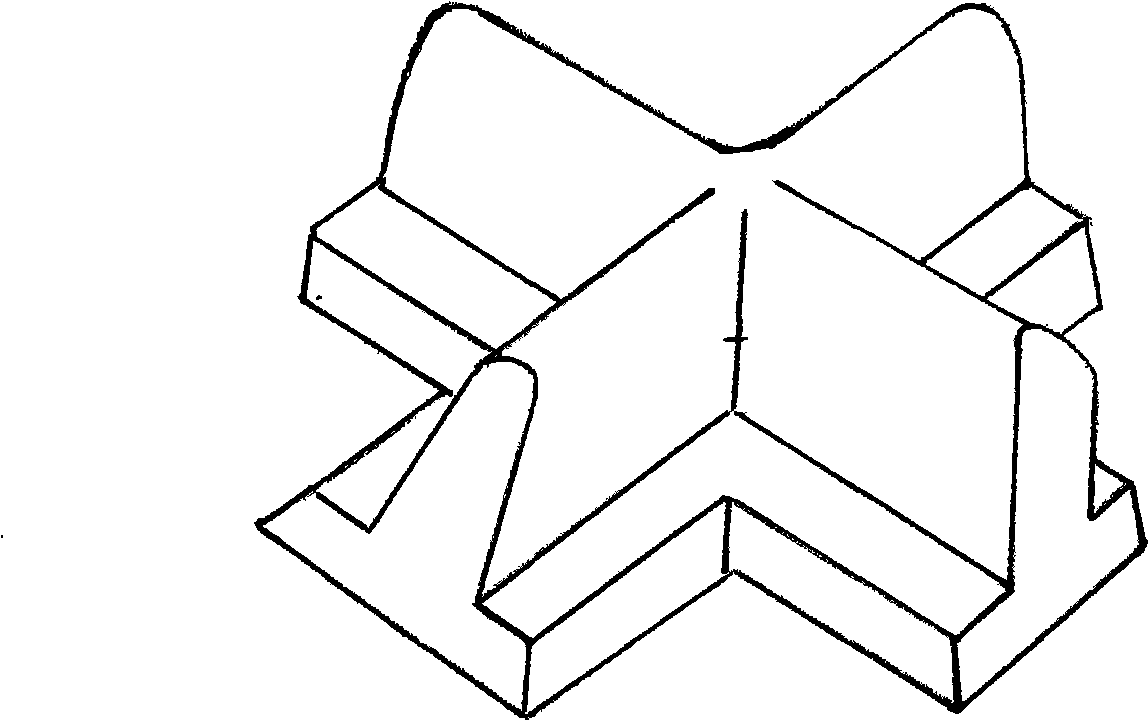

[0021] 3. Grouting molding: According to the structural characteristics of the human body and the characteristics of meridians, the product is designed so that the top surface protrudes into a turt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com