Method of manufacturing object with low reflection film

A technology of low-reflection film and manufacturing method, which can be applied to devices, coatings, instruments and other directions for coating liquid on the surface, which can solve the problems of difficulty in forming a low-reflection film, poor controllability of film thickness, etc., and achieve short drying or sintering time. , The effect of short coating time and excellent film thickness controllability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0136] Hereinafter, the present invention will be further described in detail through examples.

[0137] Examples 1 to 4 are examples, and examples 5 and 6 are comparative examples.

[0138] (Average primary particle size of fine particles)

[0139] The average primary particle size of fine particles is obtained by converting the specific surface area measured by the BET method and the volume of the spherical particles assuming that the spherical particles are uniformly dispersed in the carrier.

[0140] (Average aggregation particle size of fine particles)

[0141] The average aggregated particle size of the fine particles was measured with a dynamic light scattering particle size analyzer (manufactured by Nikkiso Co., Ltd. (Nikkiso Co., Ltd., MICROTRAC UPA).

[0142] (viscosity)

[0143] The viscosity of the coating composition was measured after adjusting the liquid temperature to 25° C. with a constant temperature bath using a B-type viscometer (manufactured by Toki San...

example 1

[0175] Embossed glass (manufactured by Asahi Glass Co., Ltd., trade name: "Solite" (soda-lime glass (ultra-clear flat glass) with low iron content and high transmittance) was prepared as a base material, and embossed glass with pear skin-like patterns formed on the surface Embossed glass), size: 100mm×100mm, thickness: 3.2mm), use cerium oxide aqueous dispersion to grind and clean the pear skin pattern surface of embossed glass, wash away cerium oxide with water, rinse with ion-exchanged water, Let it dry.

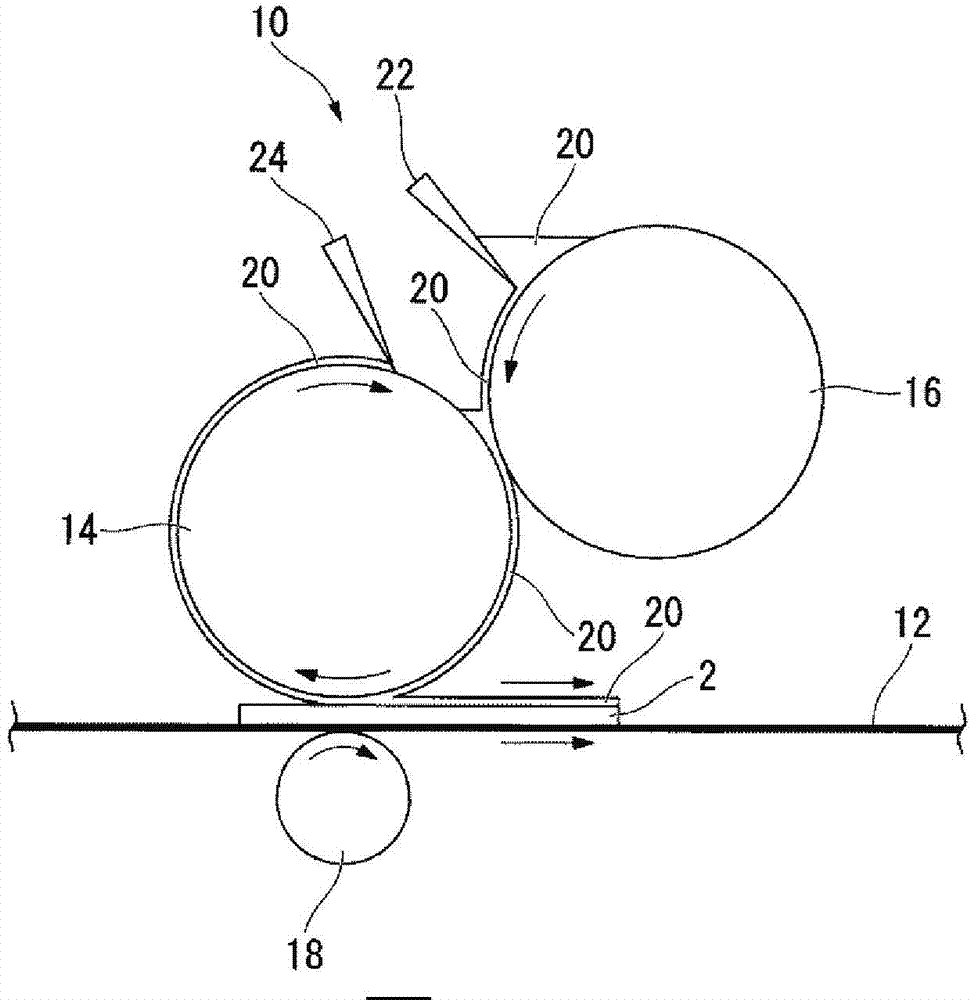

[0176]Preheat the patterned glass with a preheating furnace (manufactured by ISUZU Co., Ltd., VTR-115), and keep the glass surface temperature of the patterned glass at 30°C. On the surface, the coating composition (A) was applied by a coating roll of a reverse roll coater (manufactured by Sanwa Seiki Co., Ltd. (Sanwa Seiki Co., Ltd.). Coating conditions are as follows.

[0177] The conveying speed of the substrate: 13.8m / min,

[0178] Rotational speed of coating roller...

example 2~5

[0185] Except having changed the coating composition and coating conditions into the coating composition and coating conditions shown in Table 2, it carried out similarly to Example 1, and obtained the article which formed the low reflection film. Rate this item. The results are shown in Table 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com