Aqueous enteric coating solution and preparation method thereof

An enteric coating, water-based technology, applied in enteric coating liquid and its preparation, water-based enteric coating liquid in the field of preparation of enteric-coated preparations, can solve the problem of insufficient combination of polymer particles and plasticizers, organic solvents Problems such as high viscosity of the coating liquid and leakage loss of plasticizers, etc., to achieve the effect of tight combination, dense coating film, and less leakage loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] The preparation of embodiment 1 aqueous enteric coating solution

[0047] Take 1.3g of sodium hydroxide and add it into distilled water to make a sodium hydroxide solution for use; mix 100g Slowly add L100-55 powder to 210g ethanol in batches, stir while adding to avoid agglomeration or precipitation, stir for 2 hours to a clear solution; add plasticizer to the clear solution, stir for 30 minutes, then slowly drop The above sodium hydroxide solution is used to obtain a milky white liquid; the milky white liquid is distilled off under reduced pressure to remove ethanol to obtain an aqueous enteric coating solution. The plasticizers used in the examples are triethyl citrate (TEC) and dibutyl phthalate (DBP) as examples, and the amounts of distilled water and plasticizers used in the preparation process are shown in Table 1 and Table 2.

[0048] Amounts of Distilled Water and TEC in Examples F1-F5 of Table 1

[0049]

F1

F2

F3

F4

F5

...

Embodiment 2

[0052] The preparation of embodiment 2 free films

[0053] The water-based enteric coating solution prepared by F1-F8 in Example 1 is poured into the bottom placed horizontally. In a rectangular box (15cm×15cm×1.0cm) of the material, age at 40°C until the polymer forms a dense and uniform film; move the film to a container filled with saturated KNO 3 Put the solution in a desiccator with a relative humidity of (92.5±5)%, place it at room temperature for 10 hours to soften the film by absorbing moisture, so as to facilitate the complete removal of the film; then remove the film and dry it again at 40°C for 24 hours ; Finally, store in a desiccator with a relative humidity of 45-50%. The aqueous enteric coating solutions of F1-F8 all obtained uniform coating films.

Embodiment 3

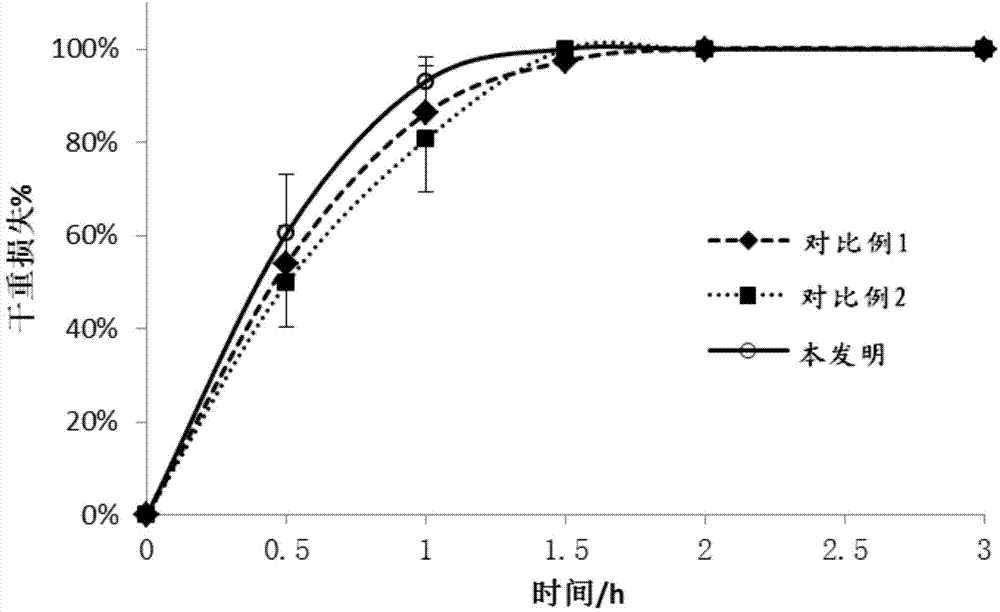

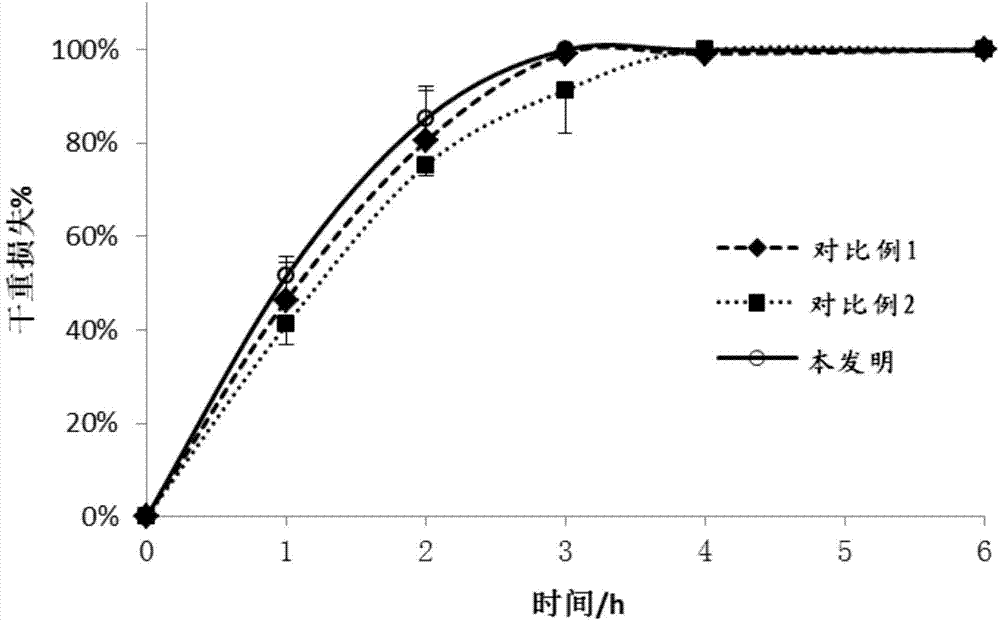

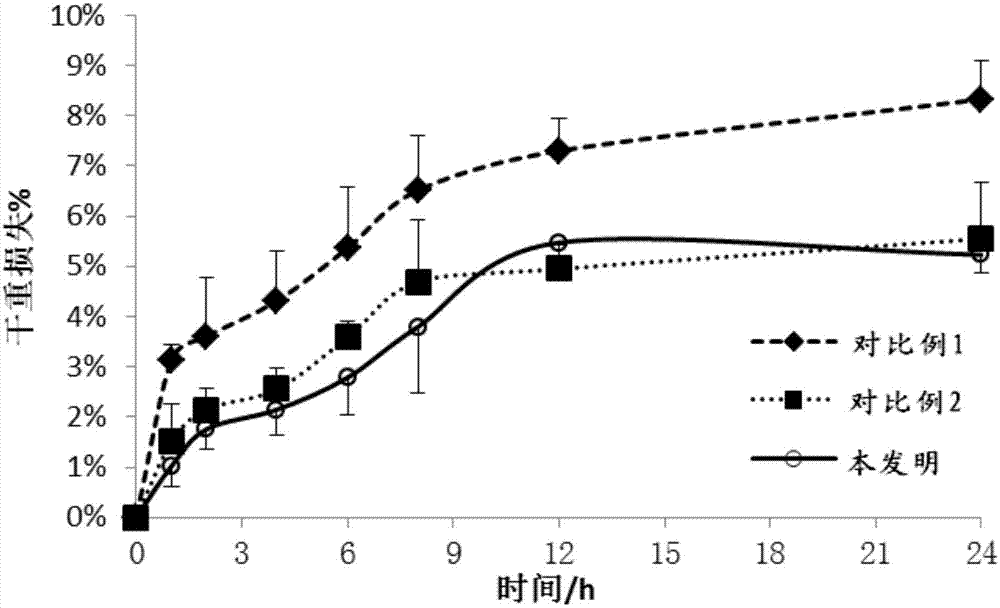

[0054] Embodiment 3 film dry weight loss rate investigation

[0055] When the film is prepared from the F4 water-based enteric coating solution in Example 2, the film is softened after absorbing moisture and cut into a rectangle of 3 cm × 1.5 cm with a scalpel, and then through subsequent drying steps, the obtained film is used as the water-based enteric coating solution of the present invention. Coating film.

[0056] Take 10g of triethyl citrate and add it to 333g of water and stir for 10min, then add 333g of coating material L30D55, stir to mix well. Prepare the film according to the preparation method of Example 2. After the film absorbs moisture and softens, cut it into a rectangle of 3cm×1.5cm with a scalpel, and then go through the subsequent drying step to make L30D55 water-based film, as comparative example 1.

[0057] 100g Slowly pour L100-55 into 600g of 95% ethanol solution in batches to avoid agglomeration or precipitation. Stir for 30-60 minutes to form ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com