High corrosion resistance granite processing method and construction process

A treatment method and construction technology, which are applied in the field of anti-corrosion treatment and construction technology for industrial buildings, can solve the problems of increasing the porosity of granite, affecting the anti-corrosion effect, etc., to reduce the water absorption rate, the construction technology is actually reliable, and the cost is low. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

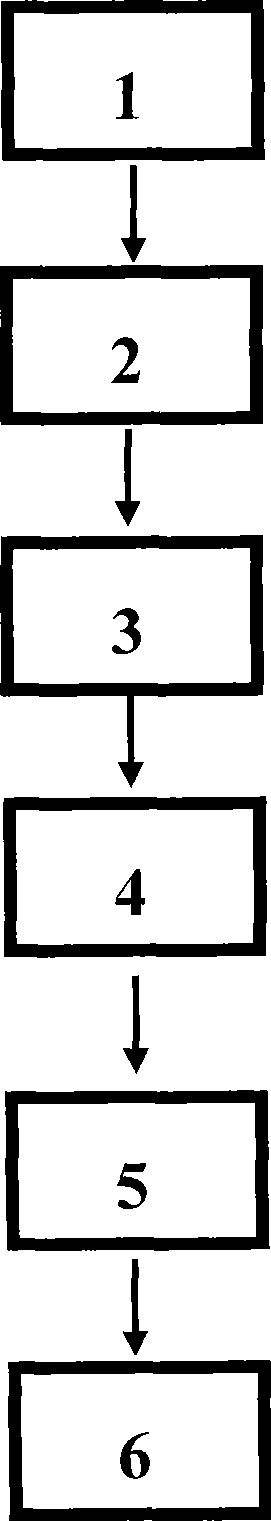

[0021] Immerse the granite in 20.0% industrial hydrochloric acid until no air bubbles appear on the surface, put it into a clear water pool to dissolve the soluble matter, rinse it with clean water, check for no acid, no reaction and water soluble matter, and dry it at room temperature for later use.

[0022] The above treated granite was dipped in high chlorinated polyethylene varnish for soaking. After the voids are completely filled, take out the resin liquid that cleans the surface of the granite to make the material surface even and smooth, and check the filling density of the resin after drying. In order to completely immerse the resin without leaving gaps, this process can be repeated 1-2 times.

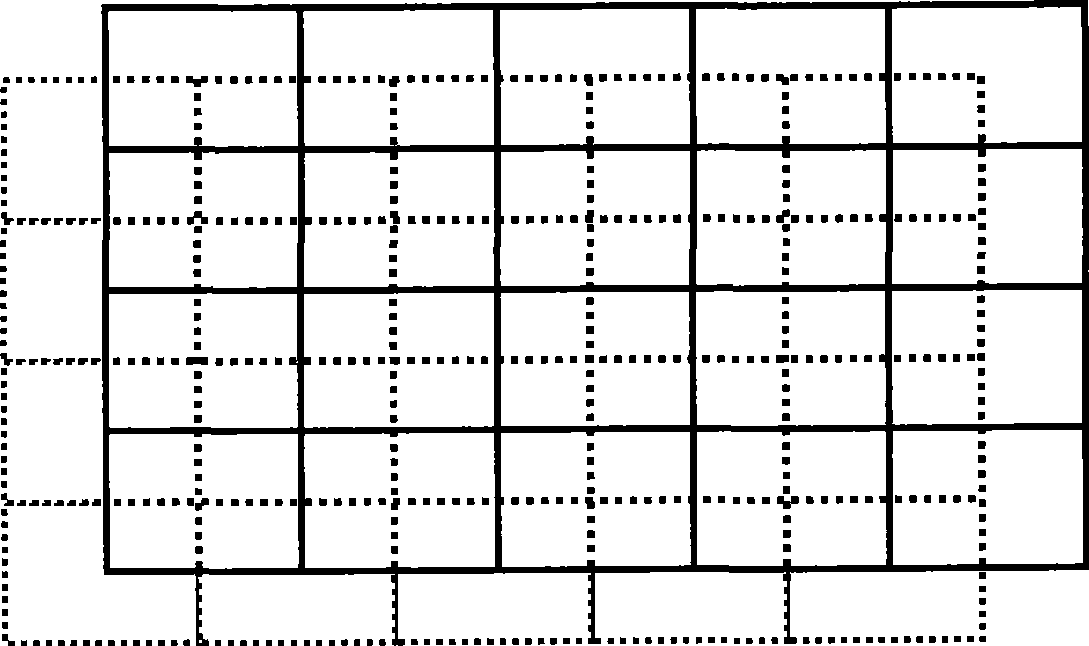

[0023] Paste the treated granite according to the construction process in the attached drawing (2) of the manual.

Embodiment 2

[0025] Immerse the granite in 15.0% industrial sulfuric acid and 5.0% acetic acid until no air bubbles appear on the surface, put it into a clear water pool to dissolve soluble matter, rinse with clean water, check for no acid, no reaction and water soluble matter, and dry at 105°C spare.

[0026] Dip the above treated granite into an acrylic varnish for soaking. After the voids are completely filled, take out the resin liquid that cleans the surface of the granite to make the material surface even and smooth, and check the filling density of the resin after drying. In order to completely immerse the resin without leaving gaps, this process can be repeated 1-2 times.

[0027] Paste the treated granite according to the construction process in the attached drawing (2) of the manual.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com