Novel method for crosslinking acrylonitrile butadiene by supported transient metal

A transition metal and nitrile rubber technology, applied in the field of cross-linked nitrile rubber, can solve the problems of material properties, uncoordinated metal salts, and low coordination efficiency, and achieve stable performance, excellent mechanical properties, and coordination efficiency. added effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Dissolve 2 grams of anhydrous copper sulfate in 300 mL of water, then add the resulting solution into 20 grams of carbon black N220 under stirring, impregnate for 48 hours, and then slowly evaporate the water to dryness under stirring to obtain a loaded sample. At this time, the surface of the sample and No white or blue copper salt particles appeared on the container wall. The loaded samples were dried at 160°C for 24 hours. Then it was mixed evenly with 40 grams of nitrile rubber (DN003, with acrylonitrile content of 50%, Mooney viscosity of 78) on a two-roll mill, and then hot pressed at 180° C. for 20 minutes to prepare a sample. Meanwhile, a comparative sample was also prepared. The process was to mix 2 grams of anhydrous copper sulfate with 20 grams of carbon black and 40 grams of nitrile rubber DN003, and then hot press at 180° C. for 20 minutes to prepare a comparative sample.

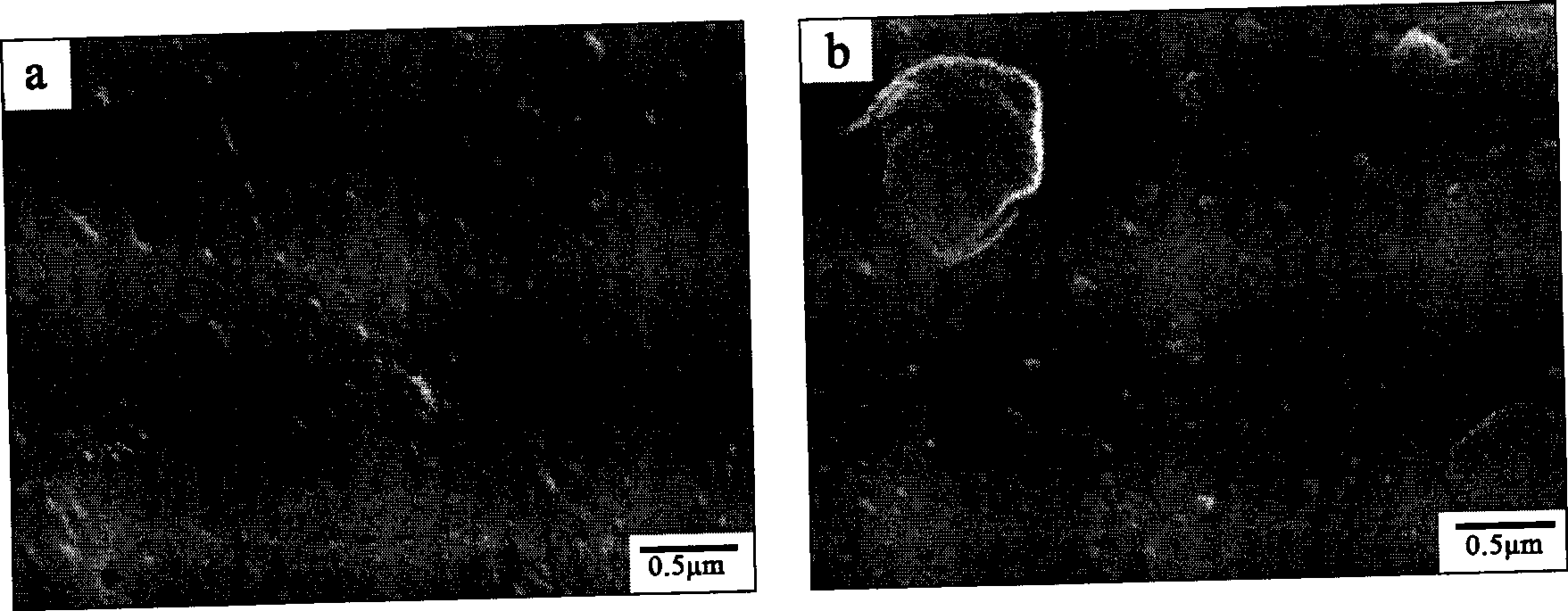

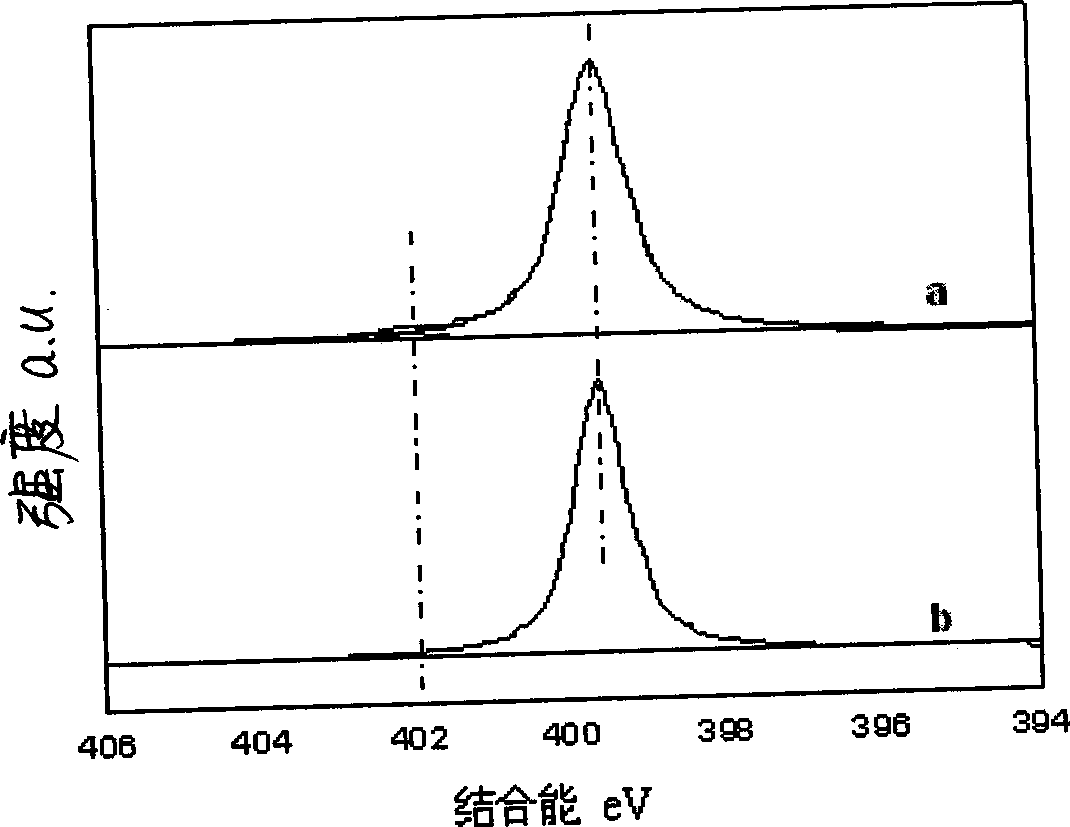

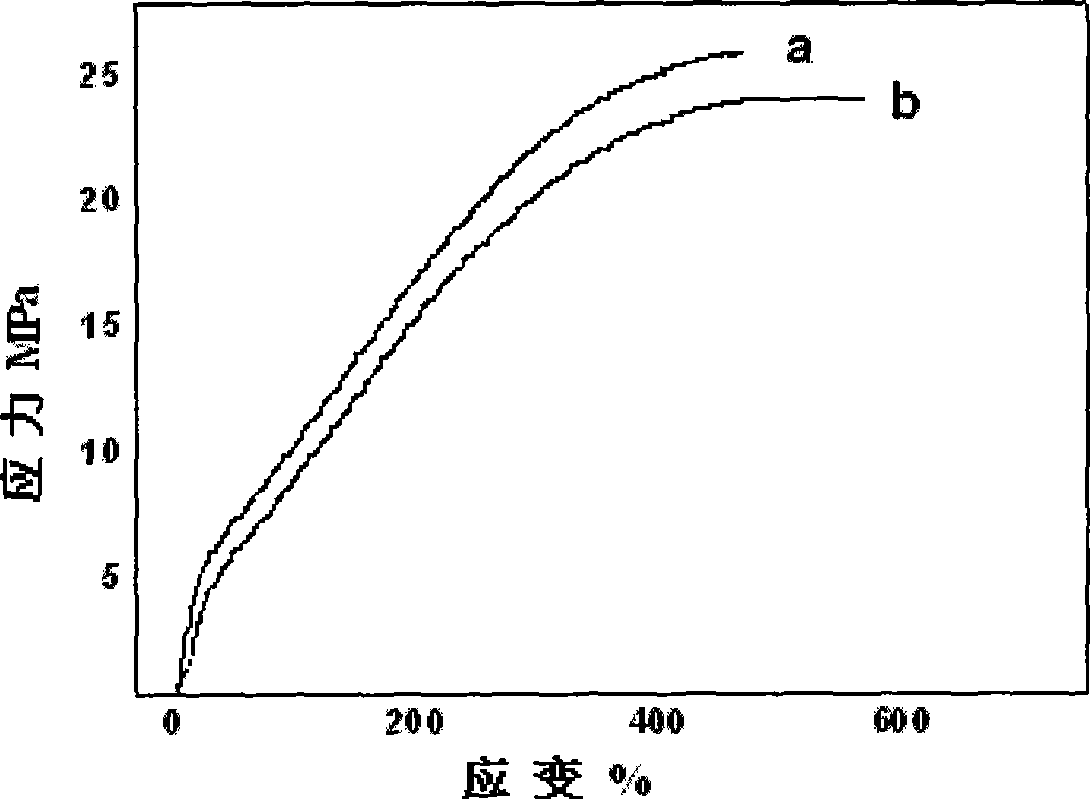

[0024] The SEM photos of the sample of this embodiment and the sample of comparativ...

Embodiment 2

[0029] Dissolve 2 grams of anhydrous copper sulfate in 400 mL of water, then add the resulting solution to 20 grams of fumed silica (with a particle size of 20 to 50 nanometers) under stirring, soak for 48 hours, and then slowly distill the water under stirring. Dry to obtain loaded samples. The loaded samples were dried at 160°C for 24 hours. Then it was mixed evenly with 40 grams of nitrile rubber (DN003, with acrylonitrile content of 50%, Mooney viscosity of 78) on a two-roll mill, and then hot pressed at 180° C. for 20 minutes to prepare a sample. Except for the loading process, comparative samples were prepared according to the same raw material ratio and the same processing conditions.

[0030] The crosslink density of the obtained sample was 1.07×10 4 (mol / cm 3 ), while the comparative sample is only 0.71×10 4 (mol / cm 3 ); The tensile strength of the obtained sample is 21.1MPa, obviously better than 16.6MPa of the comparative example sample.

Embodiment 3

[0032] Dissolve 2 grams of cobalt chloride in 300 mL of water, then add the resulting solution into 20 grams of carbon black N330 under stirring, impregnate for 48 hours, and slowly evaporate the water to dryness under stirring to obtain a loaded sample. The loaded samples were dried at 160°C for 24 hours. Then it was mixed evenly with 40 grams of nitrile rubber (acrylonitrile content is 45%, Mooney viscosity is 67) on a two-roll mill, and then hot-pressed at 180° C. for 20 minutes to prepare a sample. Except for the loading process, comparative samples were prepared according to the same raw material ratio and the same processing conditions.

[0033] The crosslink density of the obtained sample was 0.68×10 4 (mol / cm 3 ), while the comparative sample is only 0.20×10 4 (mol / cm 3 ). The tensile strength of the example sample is 23.5MPa, which is better than 20.4Mpa of the comparative example sample.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com