Coke oven alpha value on-line detecting system and coke oven heating system regulating method

A detection system and alpha value technology, which are applied in the heating of coke ovens, coke ovens, and combustible gas heating coke ovens, etc., can solve the problems of large maintenance, data lag, and complex systems, and achieve low dust interference, fast speed, and high efficiency. The effect of high detection accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

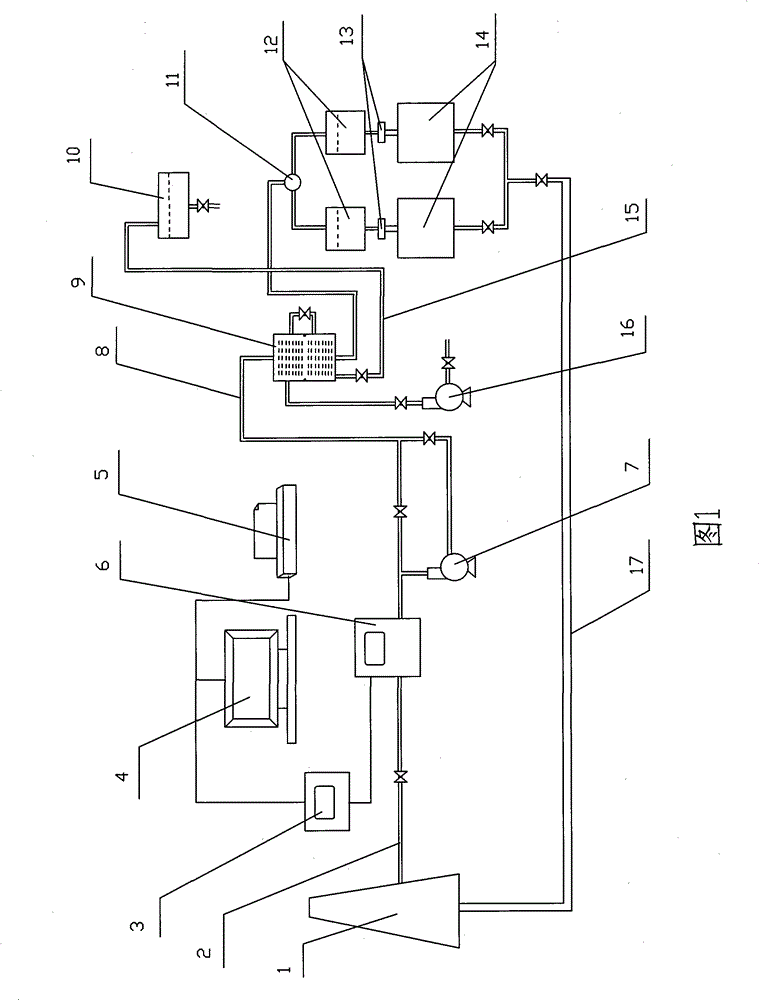

[0062] First, refer to figure 1 As shown in the schematic diagram of the system of the present invention, the gas analyzer 6 is installed between the flue gas pipe 8 and the chimney 1, so that the flue gas after the analysis of each gas content enters the chimney 1 through the pipe 2 and is discharged; the α value online analysis module 3. Connect with the gas analyzer 6 through the signal line, so that the data information of each gas content analyzed by the gas analyzer 6 is transmitted to the α value online analysis module 3 through the signal line to calculate the α value. The α value online analysis module 3 is connected to the central control room computer 4 and the printer 5, and the calculated α value can be transmitted to the central control room computer 4 in time or directly printed out by the printer 5.

[0063] Connect the side branch flue 14 of the machine coke with the vertical flue and ramp through which the flue gas passes during the heating process of the cok...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com