Heat-exchange intensification apparatus and method for indirect medium heating furnace

A technology of medium heating and heat strengthening, applied in heat storage heaters, fluid heaters, lighting and heating equipment, etc., to achieve low pollutant emissions, improved thermal efficiency, and obvious effects of energy saving and low pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

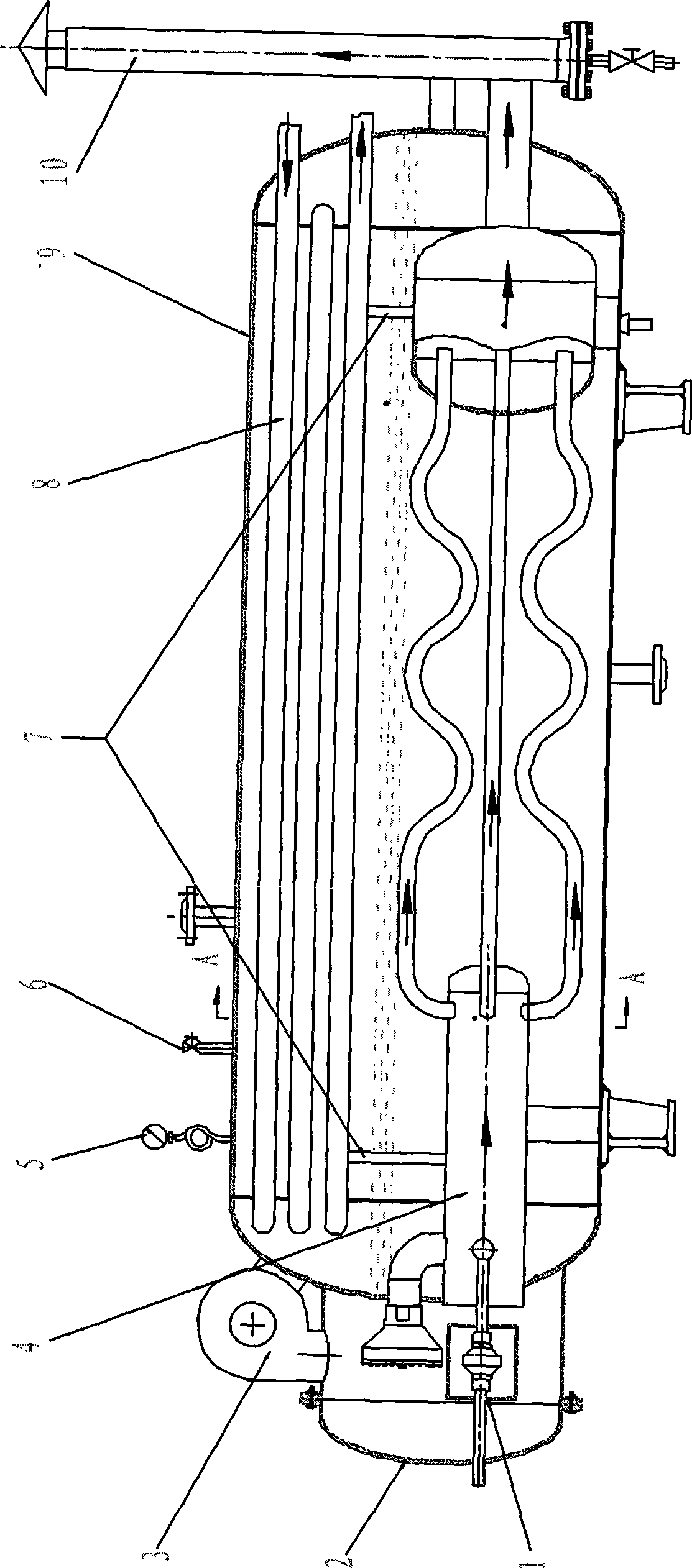

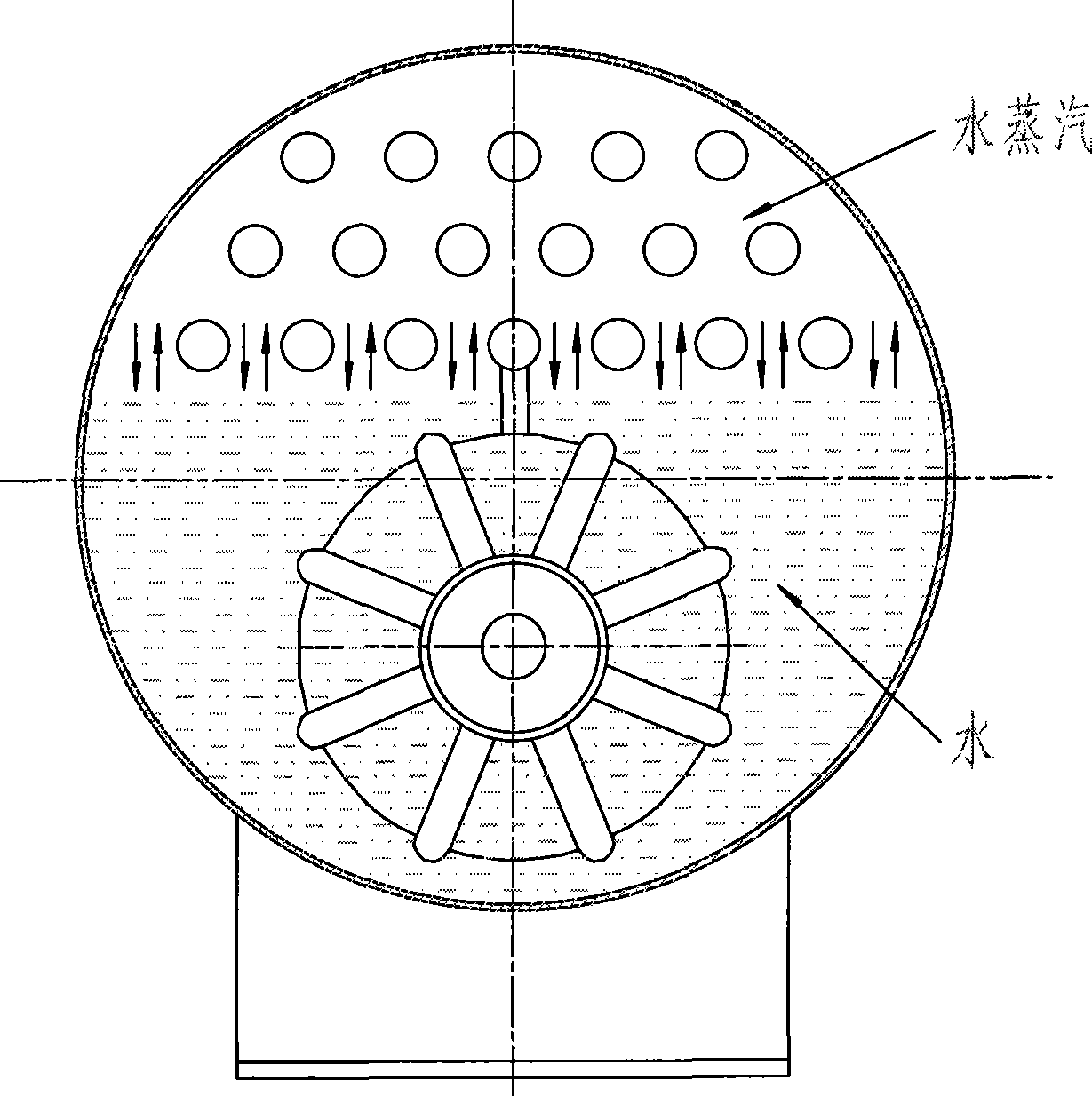

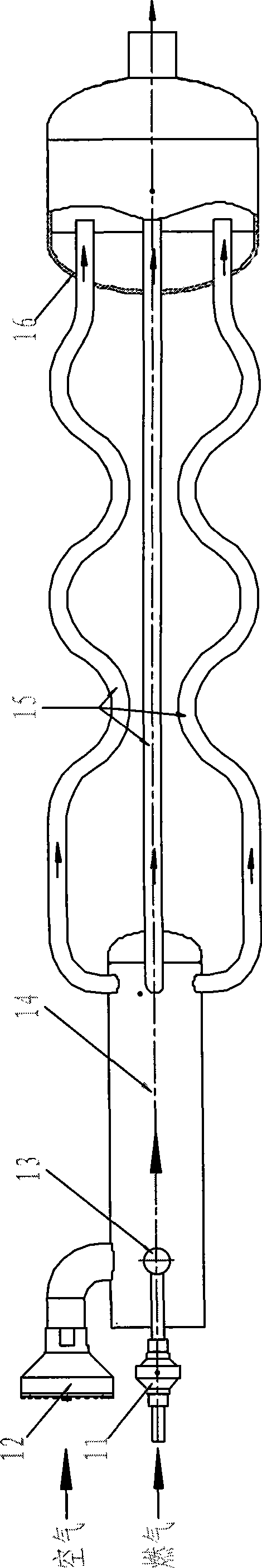

[0029] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0030] Embodiment (1) of the present invention is the mechanical structure part of the oilfield water jacket furnace such as figure 1 , figure 2 As shown, the heat exchange medium is water, which is used to heat crude oil or natural gas for export, and the fuel is natural gas. The heating furnace consists of a gas decoupling chamber 1, an air decoupling chamber 2, a start-up purge fan 3, a thermoacoustic coupling pulse burner 4, a pressure gauge or a vacuum gauge 5, a non-condensable gas exhaust device 6, a rigid connector 7, and a disc Pipe 8, pot shell 9 and exhaust pipe 10 are formed.

[0031]The connection relationship is as follows: the thermoacoustic coupling pulsation burner 4 and the coil 8 are installed in the pot shell 9 , and the thermoacoustic coupling pulsation burner 4 and the coil 8 are connected in the pot s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com