Standard CMOS fully differential optical detector and manufacturing method thereof

A photodetector and fully differential technology, which is applied in semiconductor/solid-state device manufacturing, radiation control devices, electrical components, etc., can solve problems such as asymmetry of input signals, limitation of optical receiver bandwidth and sensitivity, and imbalance of differential branches. , to achieve the effect of improving bandwidth and sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

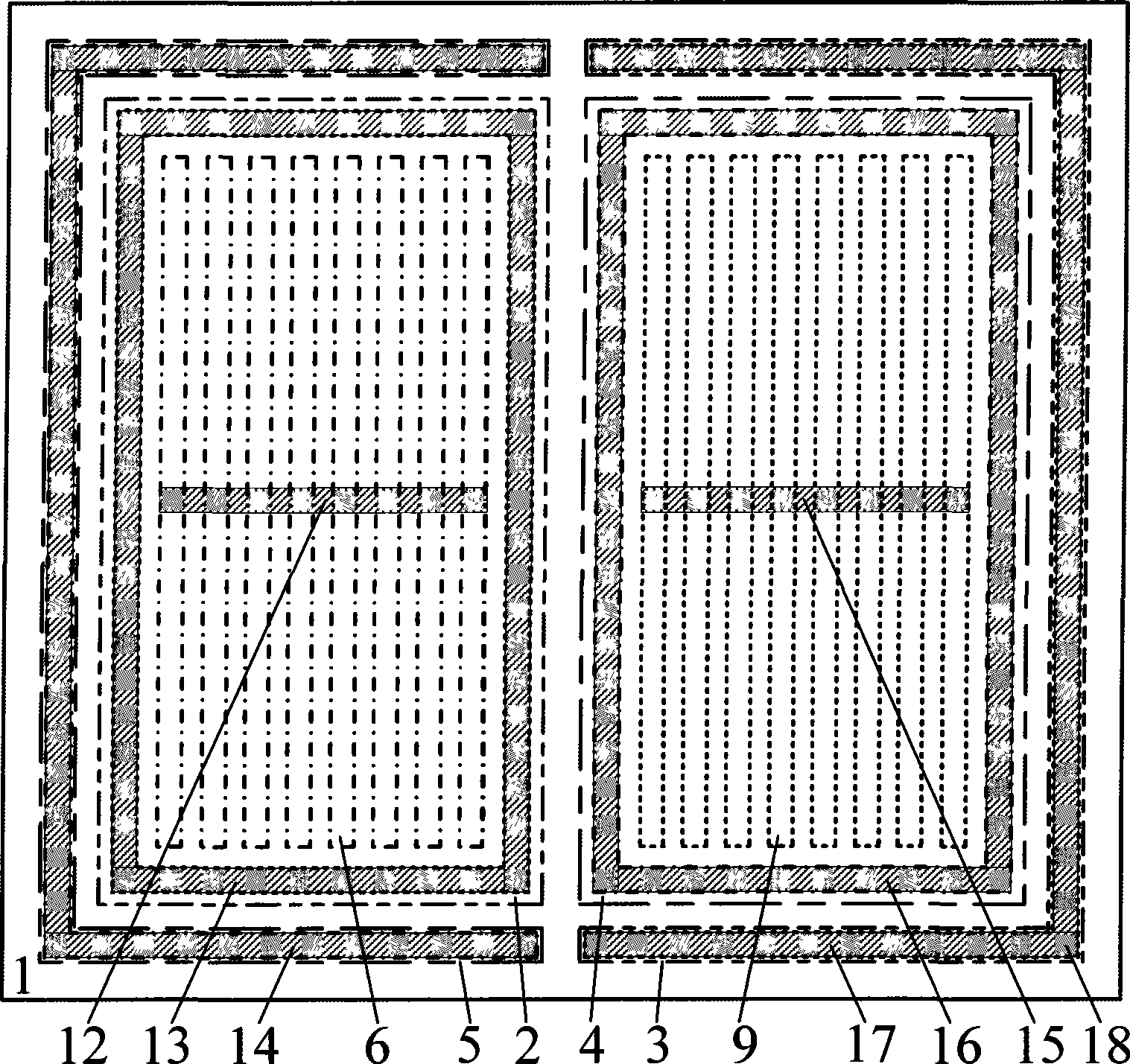

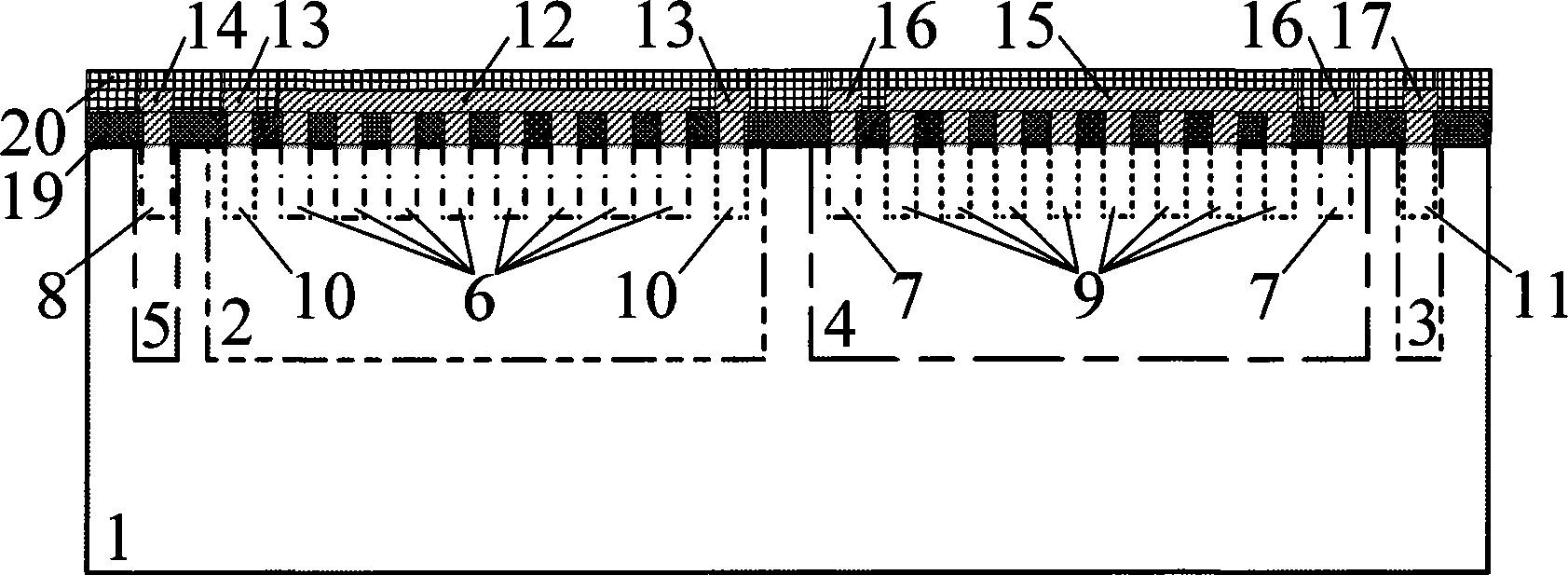

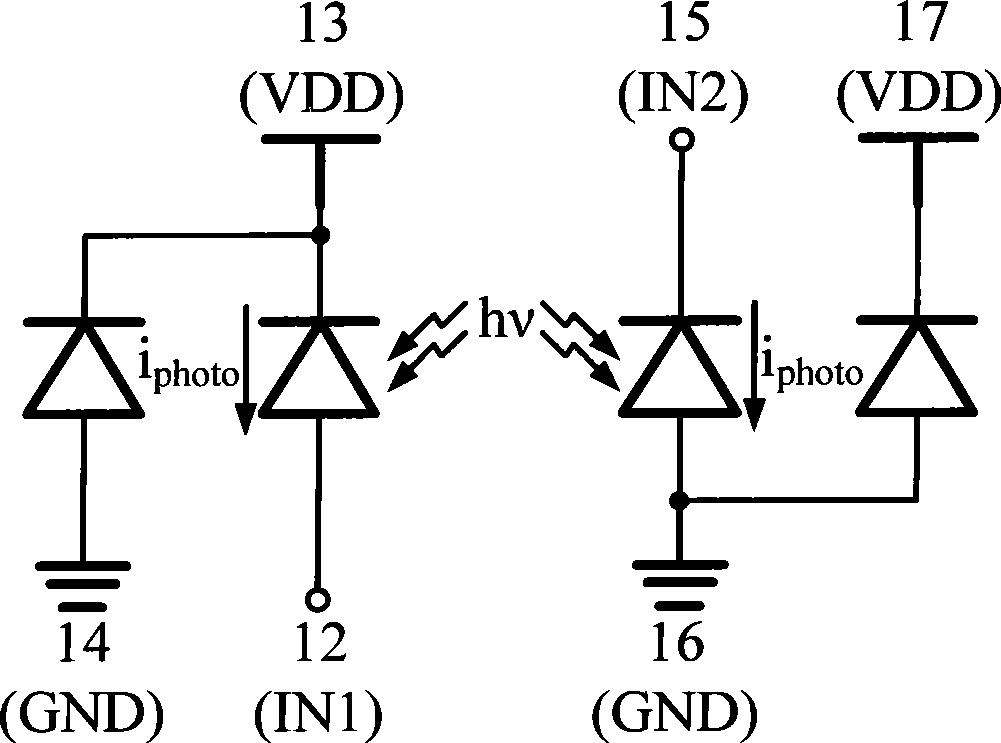

[0025] The present invention is achieved by the following methods: figure 1 It is a top view of the structure of the standard CMOS fully differential photodetector of the present invention; figure 2 It is a structural sectional view of the standard CMOS fully differential photodetector of the present invention along the longitudinal bisector; image 3 is the equivalent circuit model of the standard CMOS fully differential photodetector of the present invention when it works normally. The present invention is described in detail below in conjunction with accompanying drawing and embodiment:

[0026] figure 1 with figure 2 The manufacturing process flow of the standard CMOS fully differential photodetector shown is as follows:

[0027] First, a rectangular deep N well region 2 and a concave deep N well region 3 as well as a rectangular high voltage P well region 4 and a concave high voltage P well region 5 are sequentially fabricated on a P-type substrate 1 . Among them, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com