Paper comprising fiber of citrus peel

A technology of citrus peel and peel fiber, which is applied in the fields of fiber raw material processing, textile and papermaking, non-woody plant/crop pulp, etc. Bark powder and wolfberry fiber are not well bonded, bulky, etc., to achieve the effects of reduced production costs, good touch and hygroscopicity, and beautiful colors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

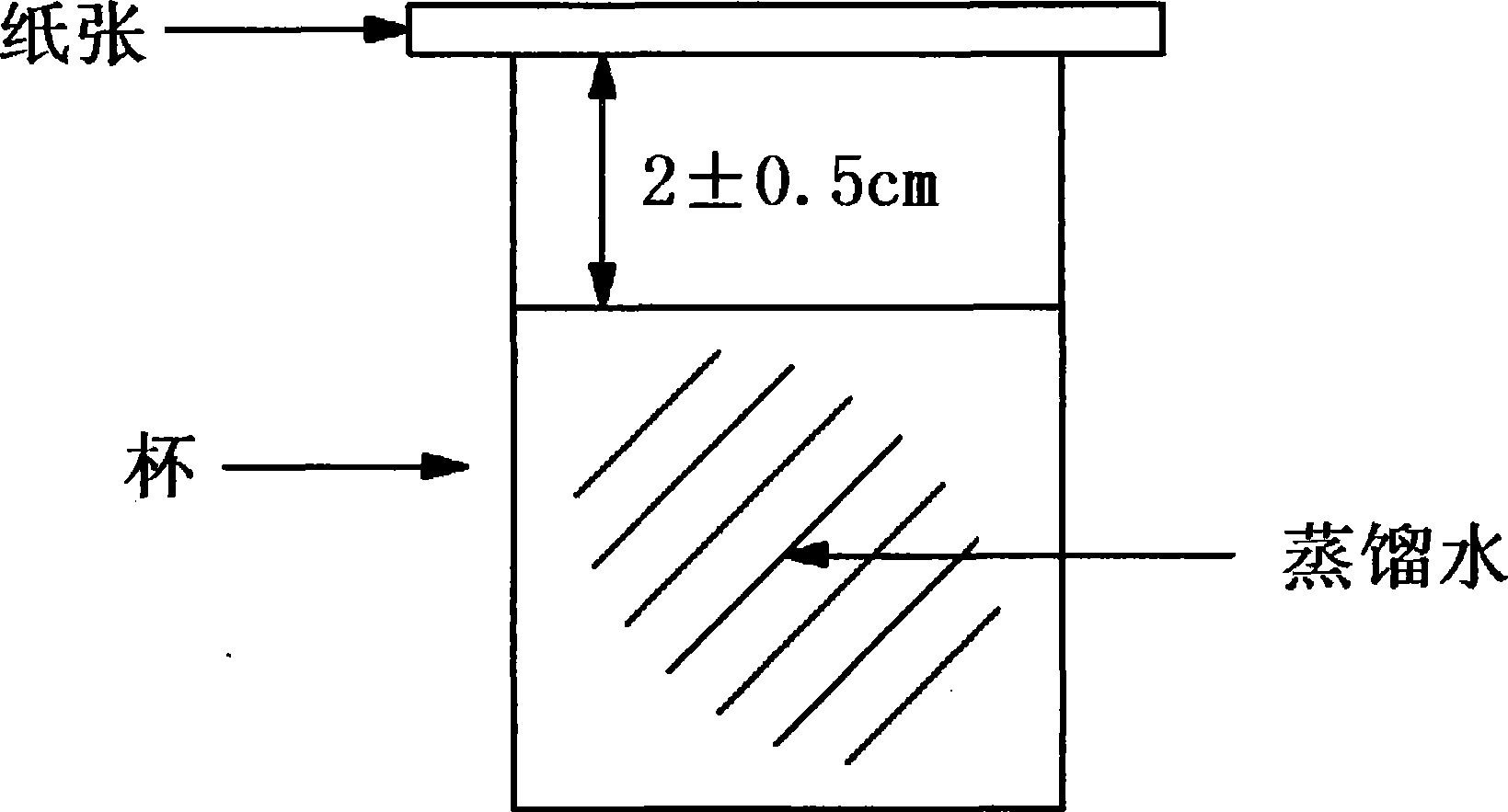

Method used

Image

Examples

Embodiment 1

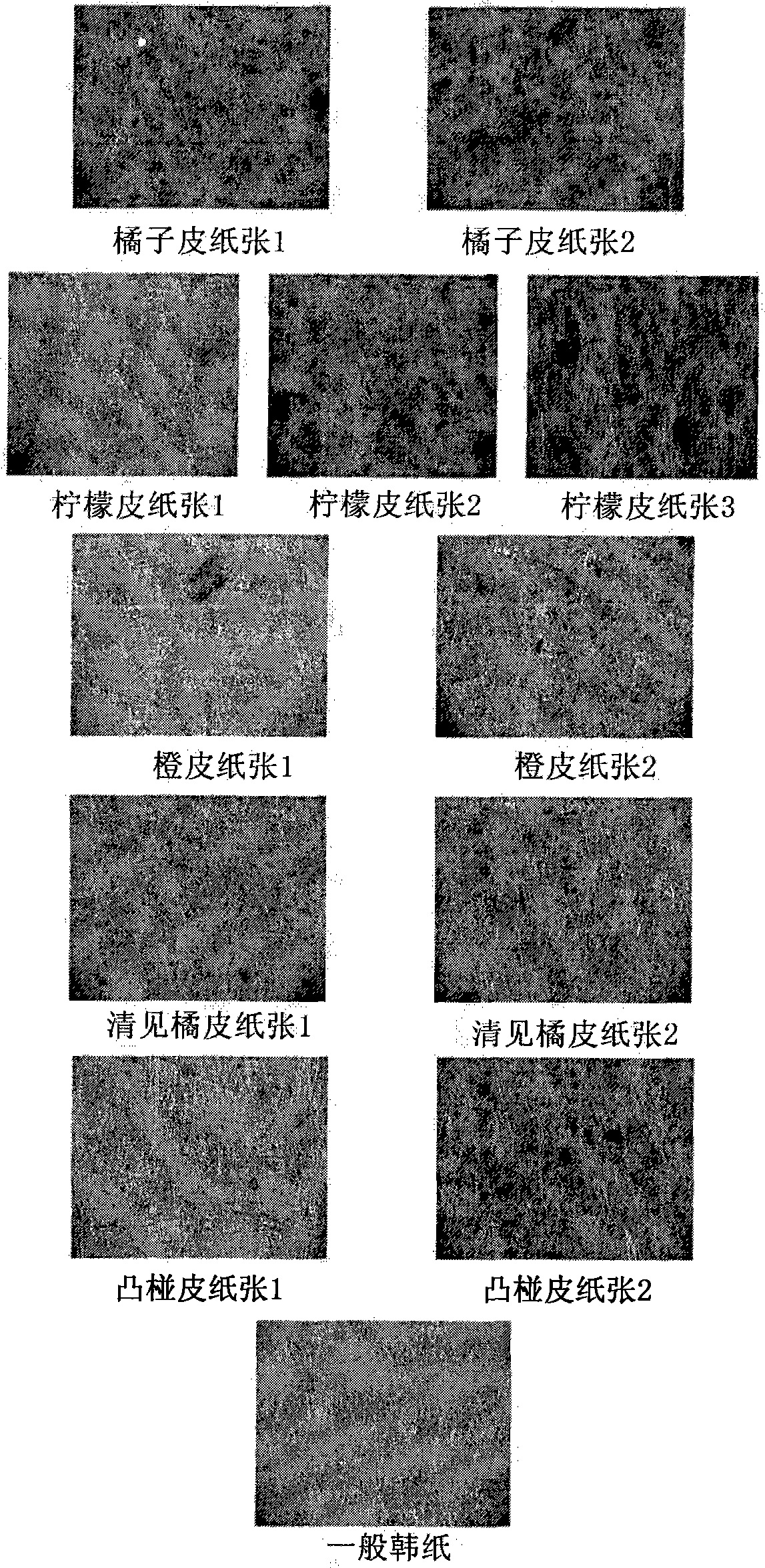

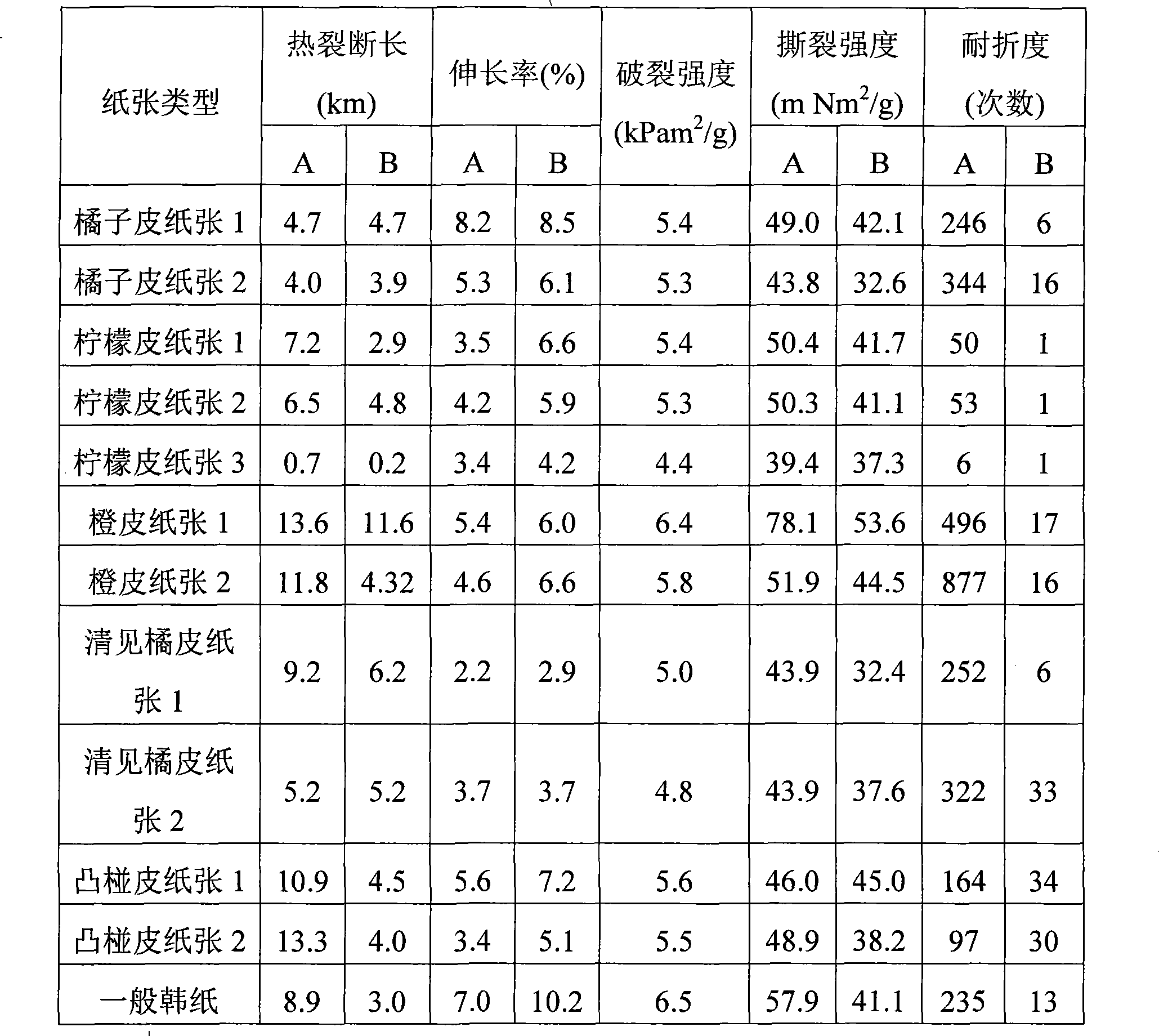

[0018] [Example 1] Making of Orange Peel Paper 1

[0019] Put 200g of dried orange peel into 5% sodium hydroxide solution, cook at 100°C for 30 minutes, and soak out the cellulose oil. Pull out the boiled pericarp and wash it with water for 3 times, then put it into a beater together with 1.8kg of water and carry out a 20-minute beating process to make orange peel fiber.

[0020] The Chinese wolfberry fiber 10kg (moisture content is 90% by weight) that Chinese wolfberry beating is made, the orange peel fiber 2kg that above-mentioned beating is made and PEO 45g are mixed and stirred and put into the paper-making cylinder, utilize sandwich former (twin -wire sheet former) after papermaking, put it into a dehydrator for dehydration and compression to obtain a uniform basis weight. Paper in a compressed and semi-dry state (moisture content 40% by weight) is brushed with a dry brush on a hot plate dryer and made flat and in close contact (stack-by-stackmanner), and then dried to m...

Embodiment 2

[0021] [Example 2] Making of Orange Peel Paper 2

[0022] Except that the orange peel fiber 10kg made after the wolfberry beating, the orange peel fiber 4kg made by beating and the PEO 45g are mixed and stirred, all the other production processes are the same as in Example 1, and the paper made in this embodiment is orange peel paper2.

Embodiment 3

[0023] [Example 3] Production of Lemon Peel Paper 1

[0024] Except that lemons are used instead of oranges, the rest of the production process is the same as in Example 1, and the paper made in this example is Lemon Peel Paper 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com