Sedan B-post high-strength plate cold stretching-forming die and technique

A high-strength plate and stretch forming technology, applied in the field of disciplines, can solve the problems of complex forming process, low work efficiency, increased energy consumption, etc., and achieve the effects of reducing environmental pollution, high work efficiency, and energy saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

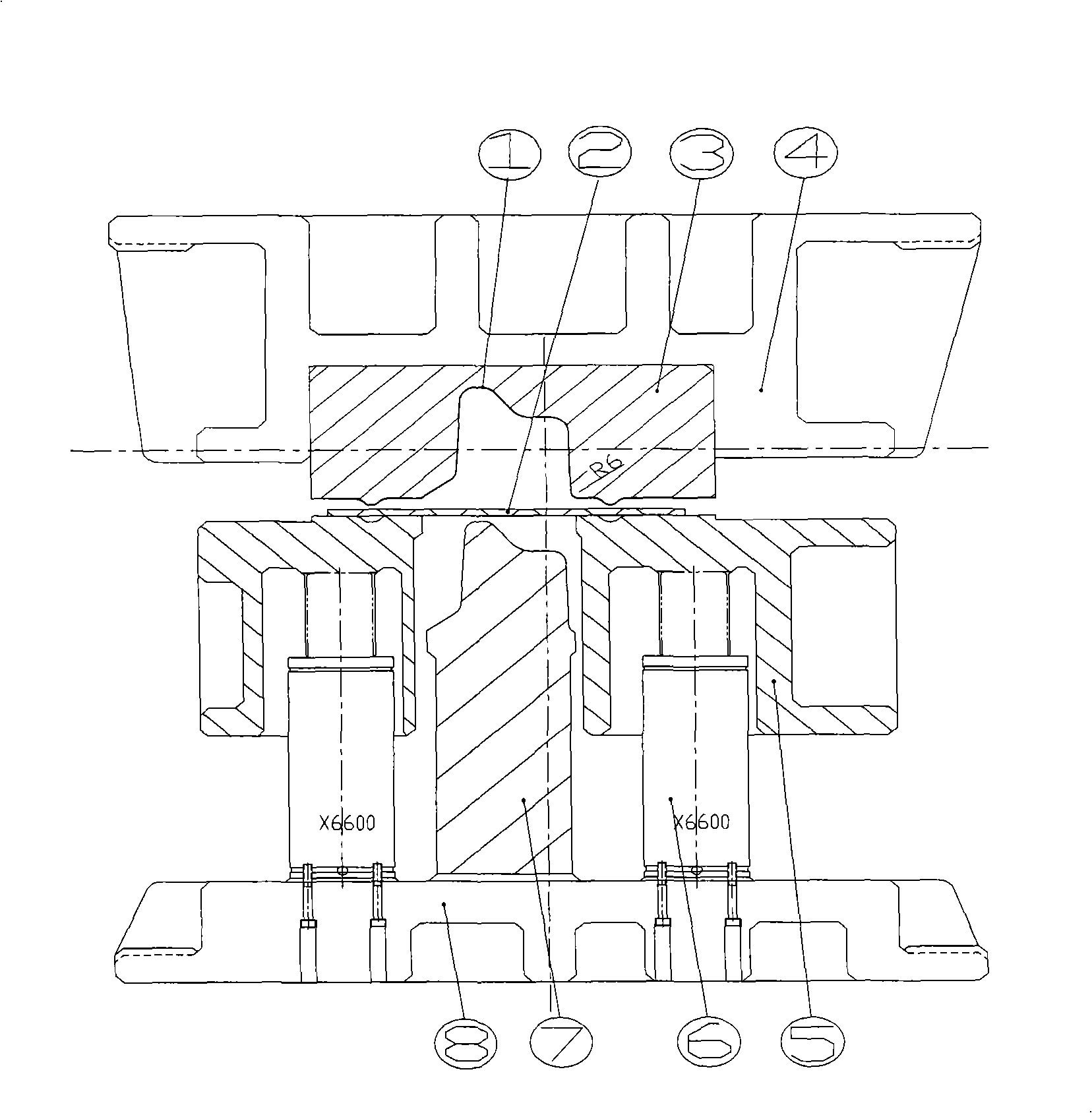

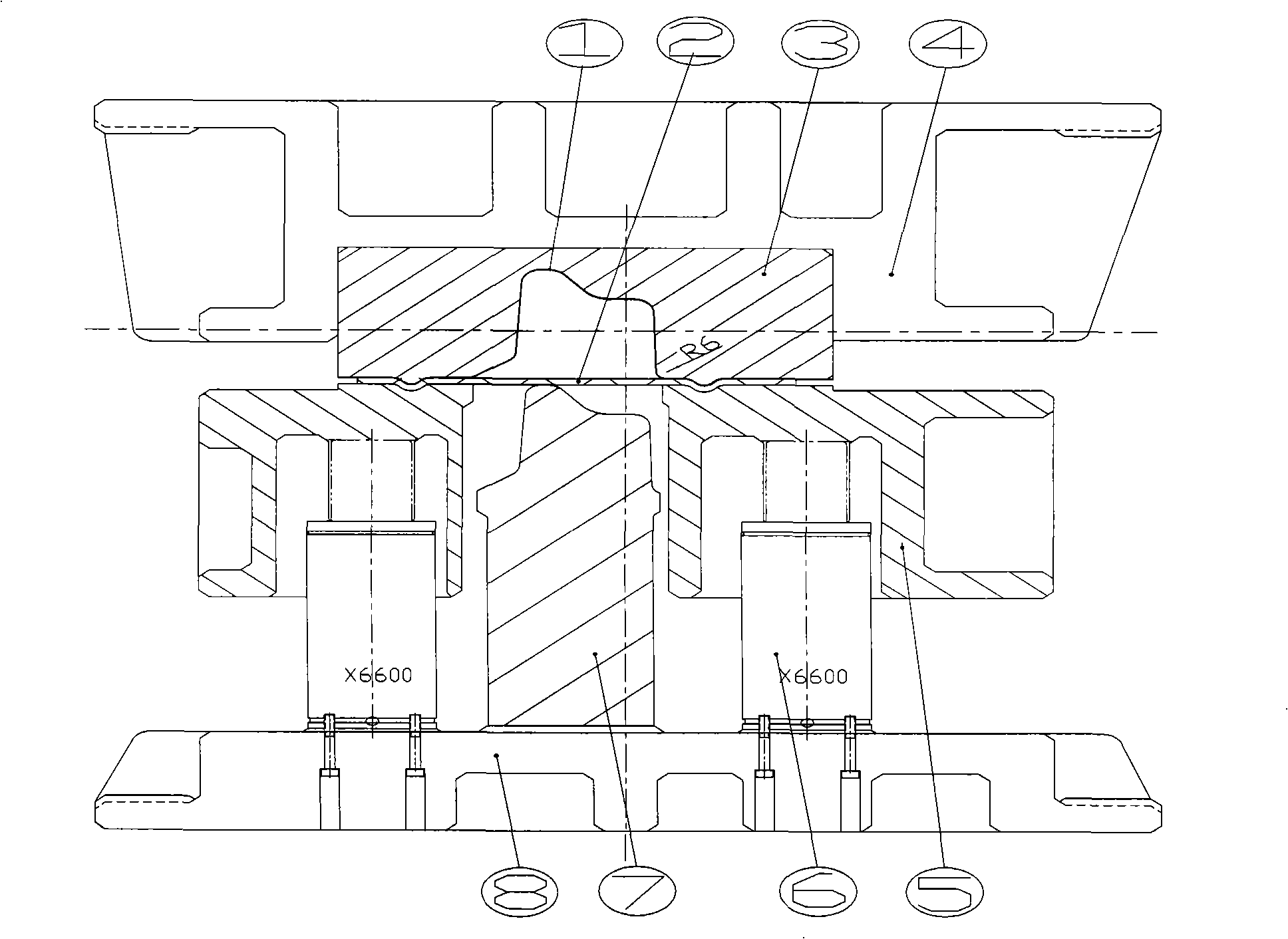

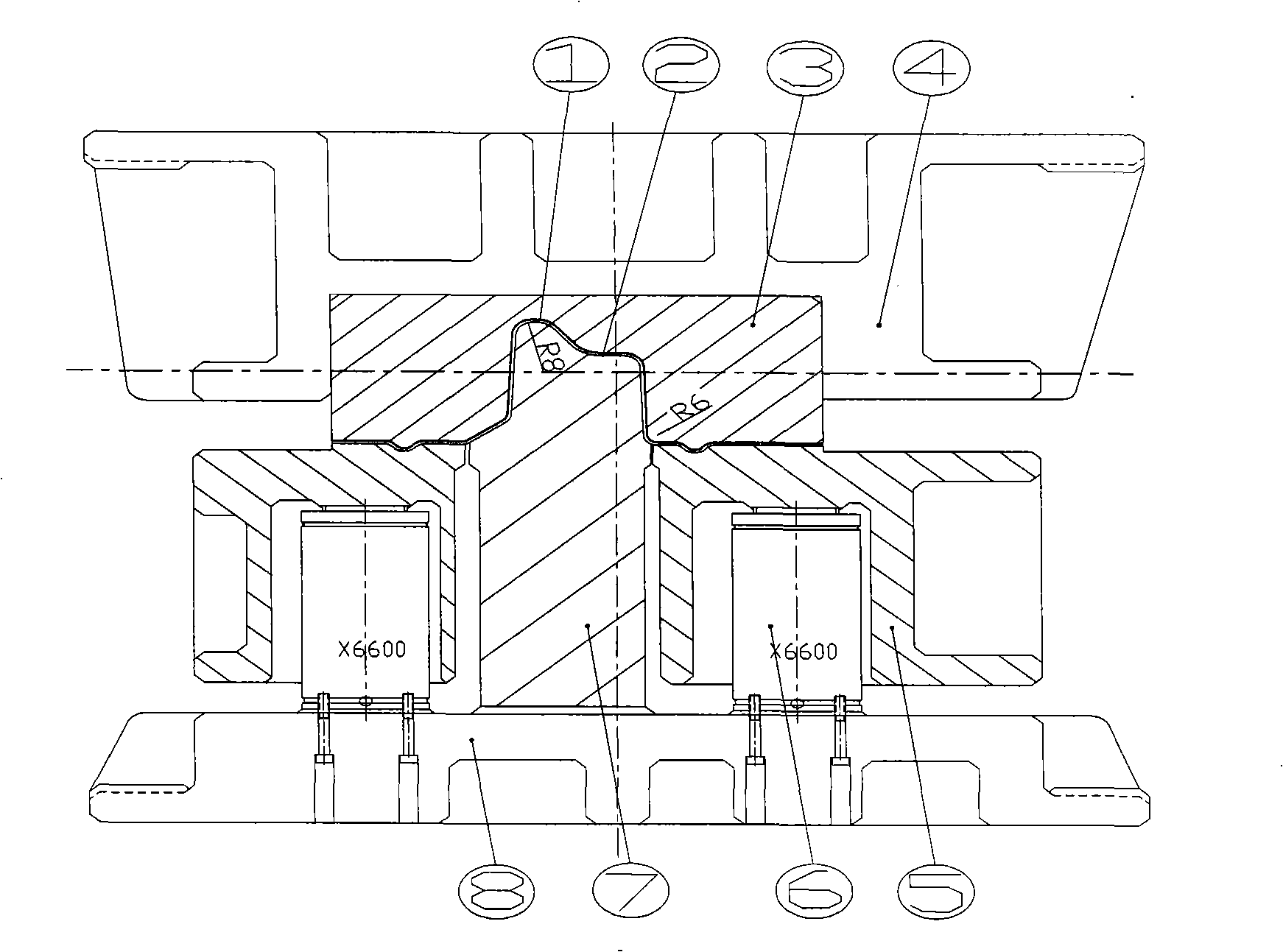

[0026] Below in conjunction with the embodiment shown in the drawings, the specific content and working process of the present invention will be further described.

[0027] The car B-pillar high-strength plate cold stretch forming structure is mainly composed of the punch 7, the die 3, the blank holder 5 and the nitrogen spring 6. The TD coating 1 is fused on the die 3, and the punch 7 is fixed on the bottom. On the die base 8; the die 3 is fixed on the upper die base 4; The bottom of the blank holder 5 is supported by a nitrogen spring 6 mounted on the lower mold base 8 .

[0028] refer to figure 1 The shown car B-pillar high-strength plate cold stretch forming die of the present invention is mainly composed of TD cladding 1, die 3, upper die holder 4, blank holder 5, nitrogen spring 6, punch 7, lower die holder 8 and back Composition of material screws and connecting screws. Among them, the die 3 is fixed on the upper die base 4 through the connecting screw; the blank hol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com